A kind of preparation method of chitosan nanofiber

A technology of chitosan nanometer and chitosan solution, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of easy introduction of other impurities, poor dispersion stability, and limited application, so as to improve product quality, Guarantee product quality and use quality, and the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

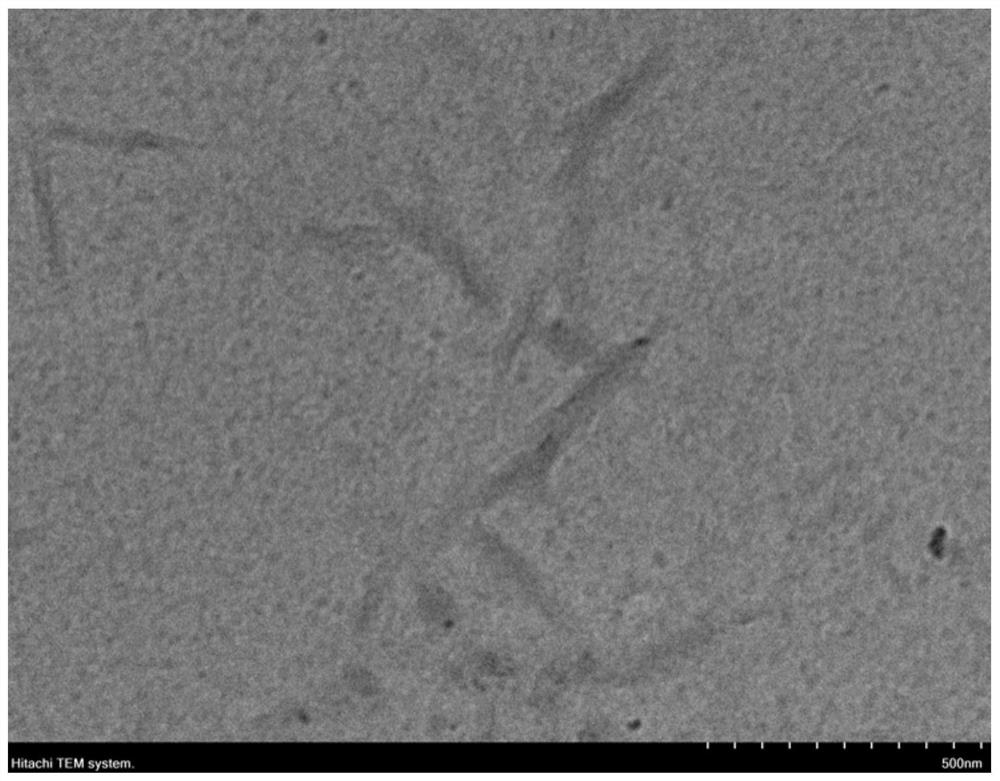

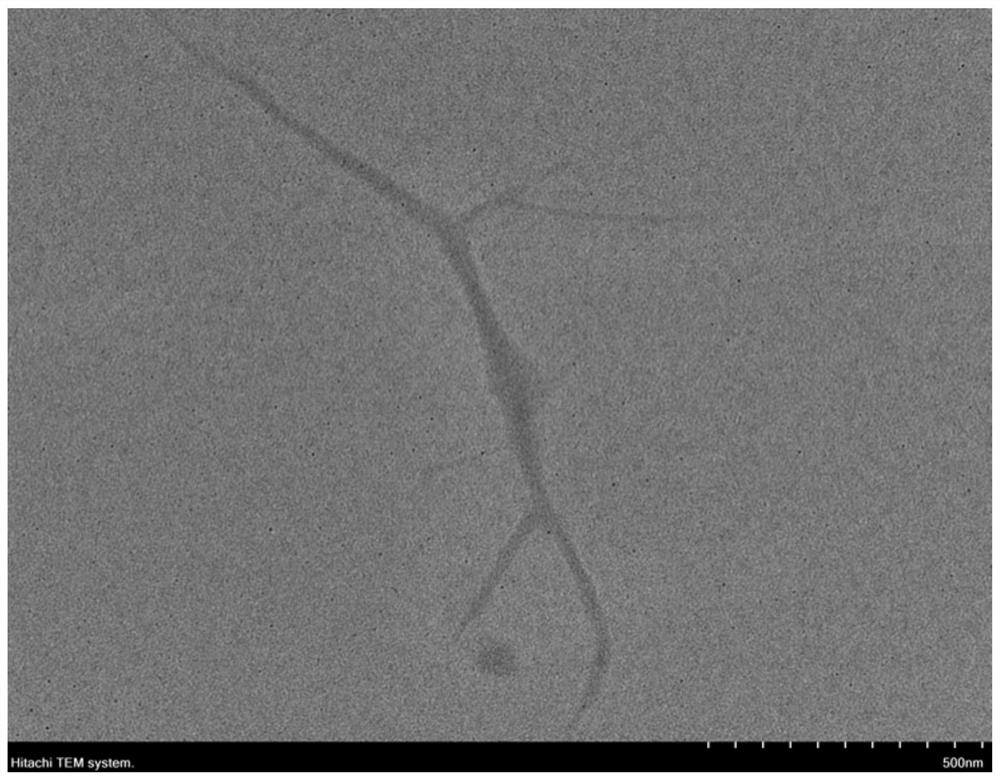

Image

Examples

Embodiment 1

[0032] 1) Prepare 100ml of 1% acetic acid solution, add 1g of chitosan with a molecular weight of 50,000 and a degree of deacetylation of 90% to the acetic acid solution at 50°C and continue stirring until the chitosan is completely dissolved. Chitosan solution;

[0033] 2) Prepare 10ml of hydrogen peroxide solution with a mass fraction of 6%, add the hydrogen peroxide solution dropwise under the stirring condition of the chitosan solution, control the dropping time within half an hour, then continue to stir for 2h, then let it stand and cool to room temperature naturally to obtain A suspension containing degradation product A;

[0034] 3) Prepare 30ml of 1mol / L sodium hydroxide aqueous solution, slowly add it dropwise to the suspension of step 2), adjust its pH to neutral, collect the filter cake by suction, and repeat the filter cake with deionized water Wash to neutral to obtain degradation product B;

[0035] 4) Disperse the degradation product B in deionized water and stir it ...

Embodiment 2

[0038] 1) Prepare 100ml of 3% acetic acid solution, add 1g of chitosan with a molecular weight of 100,000 and a degree of deacetylation of 95% to the acetic acid solution at 55°C, and continue stirring until the chitosan is completely dissolved. Chitosan solution;

[0039] 2) Prepare 10ml of a hydrogen peroxide solution with a mass fraction of 3%, add the hydrogen peroxide solution dropwise under the stirring condition of the chitosan solution, control the dropping time within half an hour, and then continue to stir for 6 hours, then let it stand and cool to room temperature naturally to obtain A suspension containing degradation product A;

[0040] 3) Prepare 30ml of 2mol / L sodium hydroxide aqueous solution, slowly add it dropwise to the suspension of step 2), adjust its pH to neutral, collect the filter cake by suction, and repeat the filter cake with deionized water Wash to neutral to obtain degradation product B;

[0041] 4) Disperse the degradation product B in deionized water...

Embodiment 3

[0044] 1) Prepare 100ml of acetic acid solution with a mass fraction of 5%, add 3g of chitosan with a molecular weight of 200,000 and a degree of deacetylation of 80% to the acetic acid solution at 40°C, and continue stirring until the chitosan is completely dissolved. Chitosan solution;

[0045] 2) Prepare 10ml of hydrogen peroxide solution with a mass fraction of 6%, add the hydrogen peroxide solution dropwise under the stirring condition of the chitosan solution, control the dropping time within half an hour, and then continue to stir for 4 hours, then let it stand and cool to room temperature naturally to obtain A suspension containing degradation product A;

[0046] 3) Prepare 30ml sodium hydroxide aqueous solution with a concentration of 3mol / L, slowly add it dropwise to the suspension of step 2), adjust its pH to neutral, collect the filter cake by suction, and repeat the filter cake with deionized water Wash to neutral to obtain degradation product B;

[0047] 4) Disperse t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com