Construction method of spin digging pile

A construction method and technology of rotary excavation piles, which are applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reduced pile foundation bearing capacity, excessive construction period increase, and high cost, so as to reduce soil drop, The effect of shortening the construction period and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

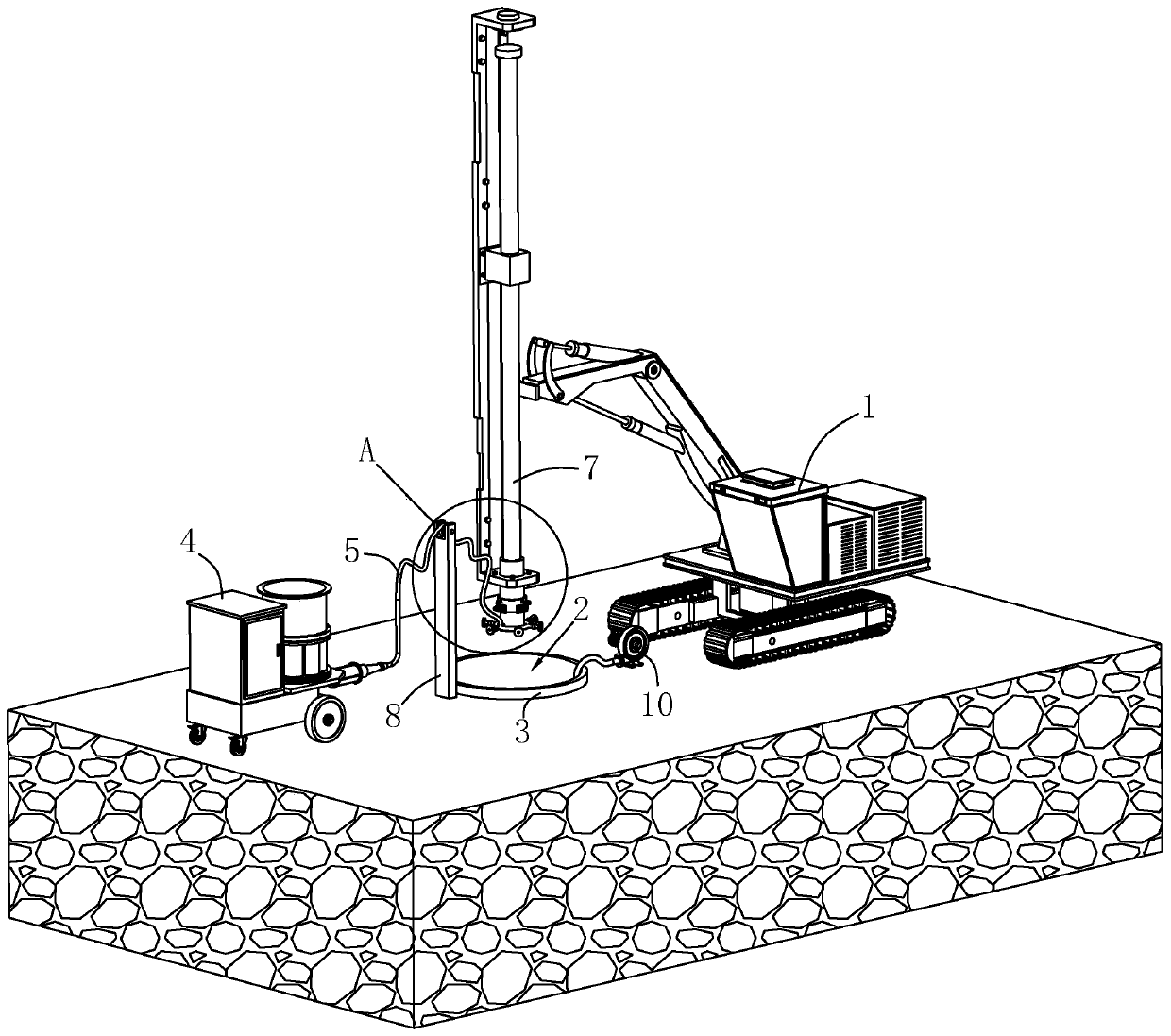

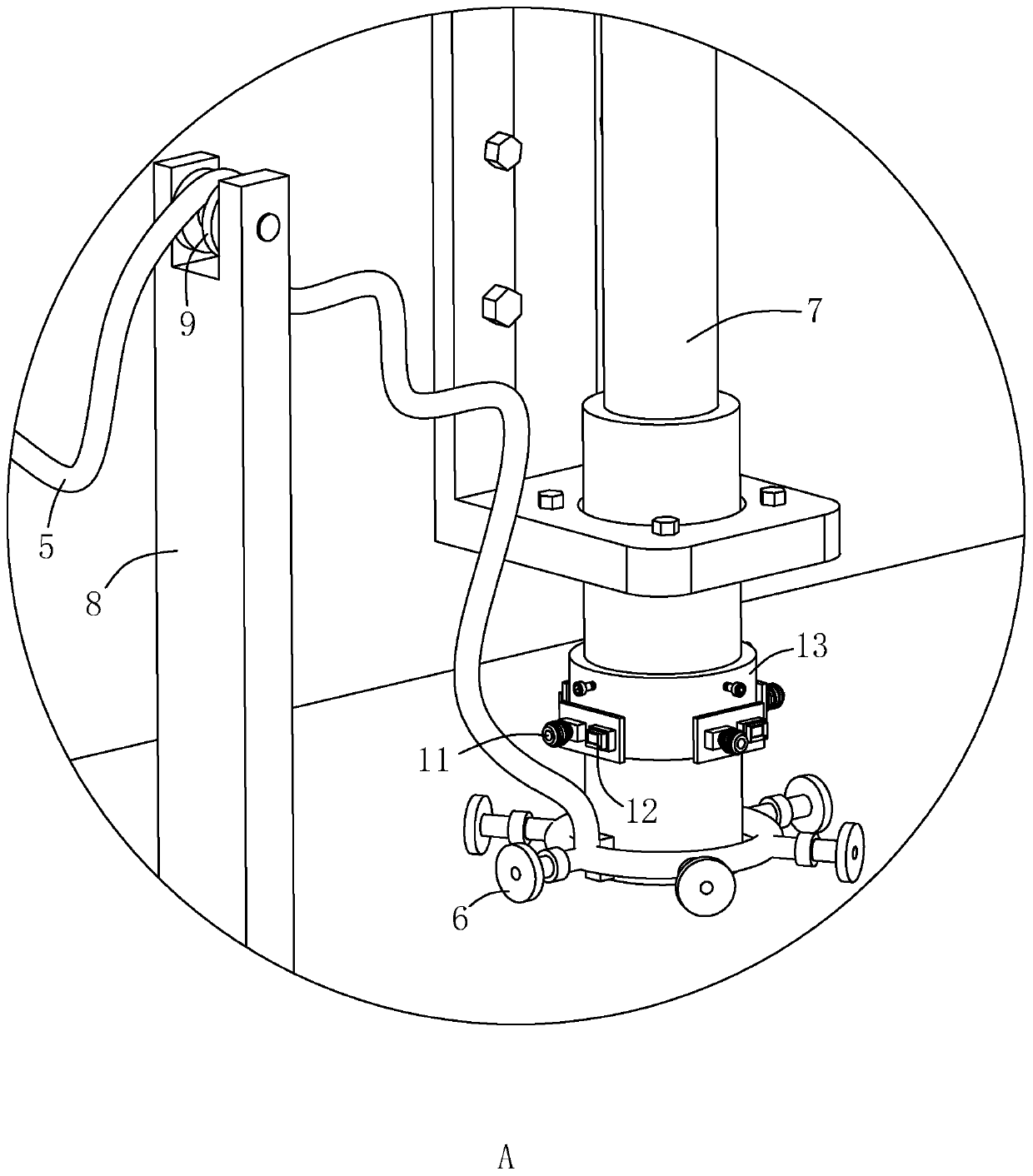

[0036] combine figure 1 with figure 2 , the rotary drilling rig 1 is located on one side of the pile hole 2, the drill pipe 7 of the rotary drilling rig 1 is aligned with the pile hole 2, and an all-steel casing 3 is buried at a depth of 1 meter to 2 meters in the pile hole 2. Retain the wall at the opening. Concrete injection machine 4 is positioned at the other side of pile hole 2, and concrete injection machine 4 comprises grouting pipe 5 and nozzle 6, and grouting pipe 5 is connected with the body of concrete injection machine 4, and the other end of grouting pipe 5 is connected with nozzle 6 connected. There are six nozzles 6, and a circumferential pipe is arranged at the connection between the grouting pipe 5 and the nozzle 6, and the six nozzles 6 are connected to the peripheral pipe respectively, and are evenly arranged on the peripheral pipe, and the six nozzles 6 are on the same plane. The outer ring of the circumferential pipe is provided with a magnet, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com