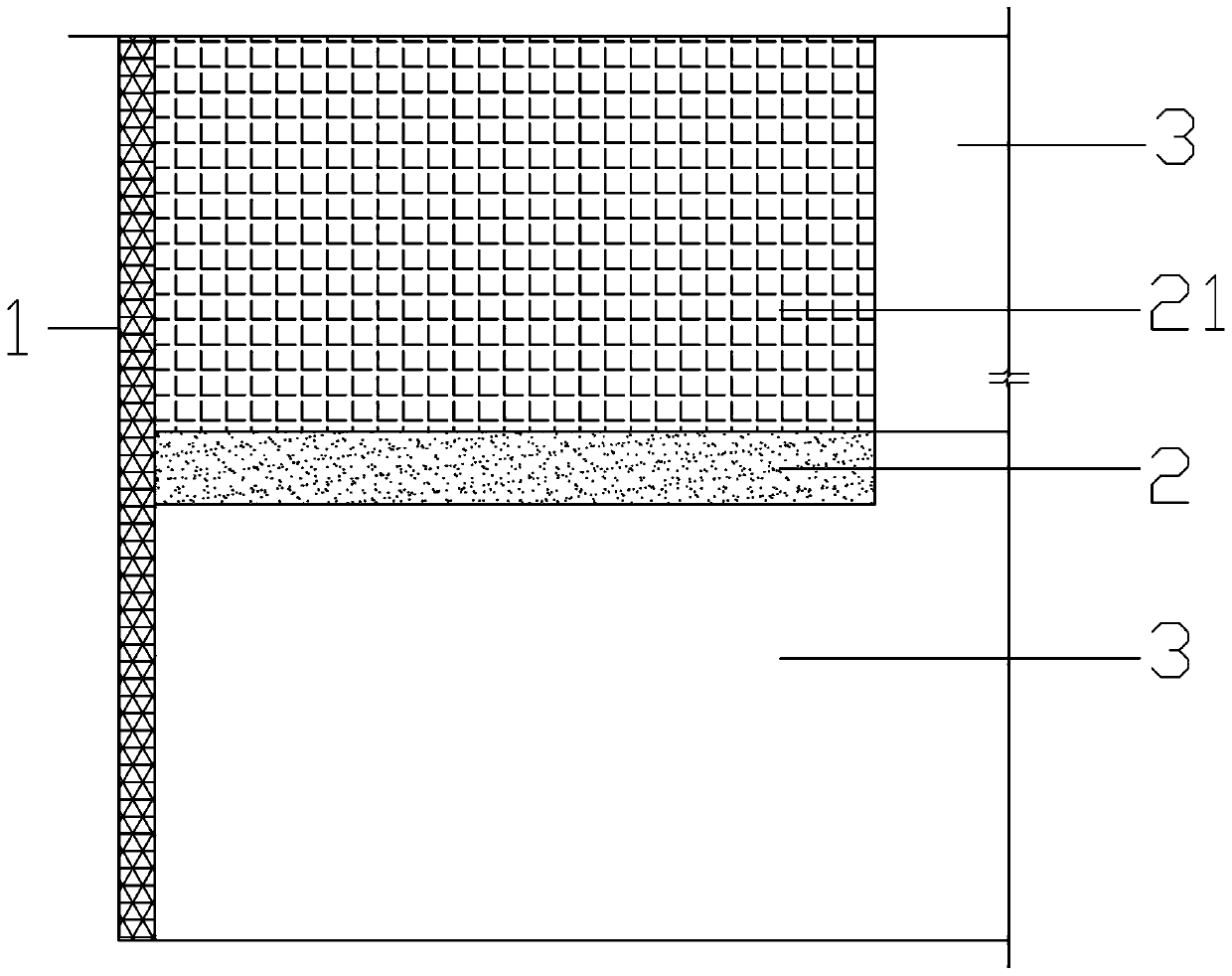

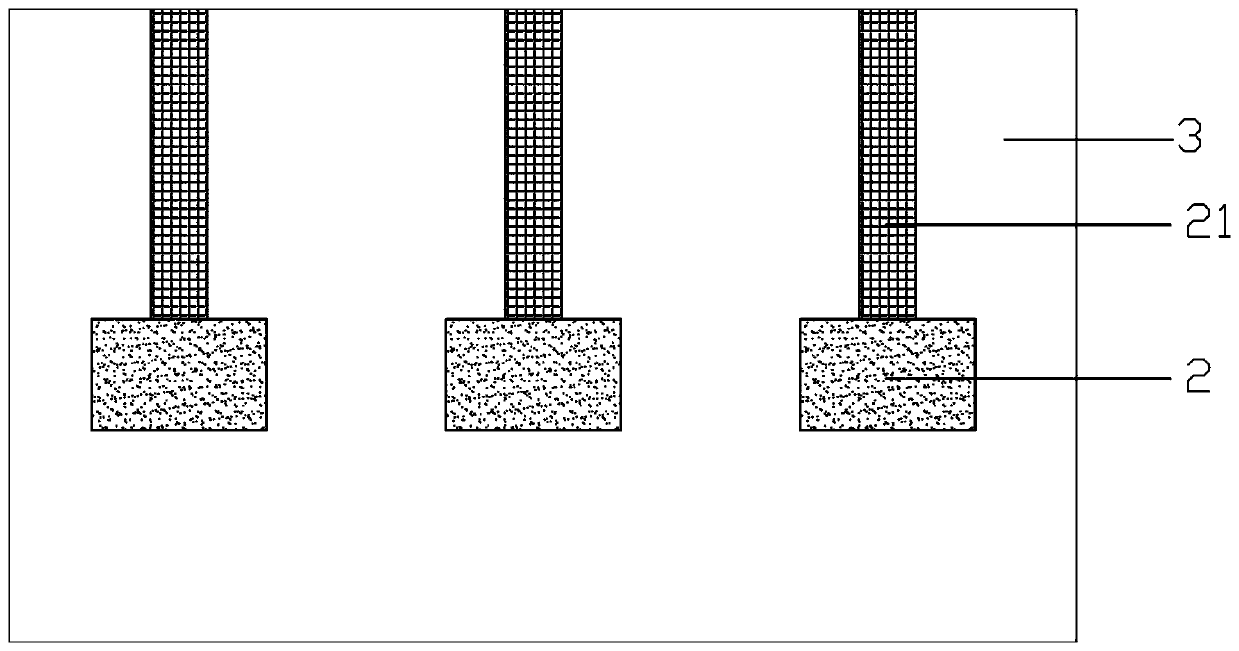

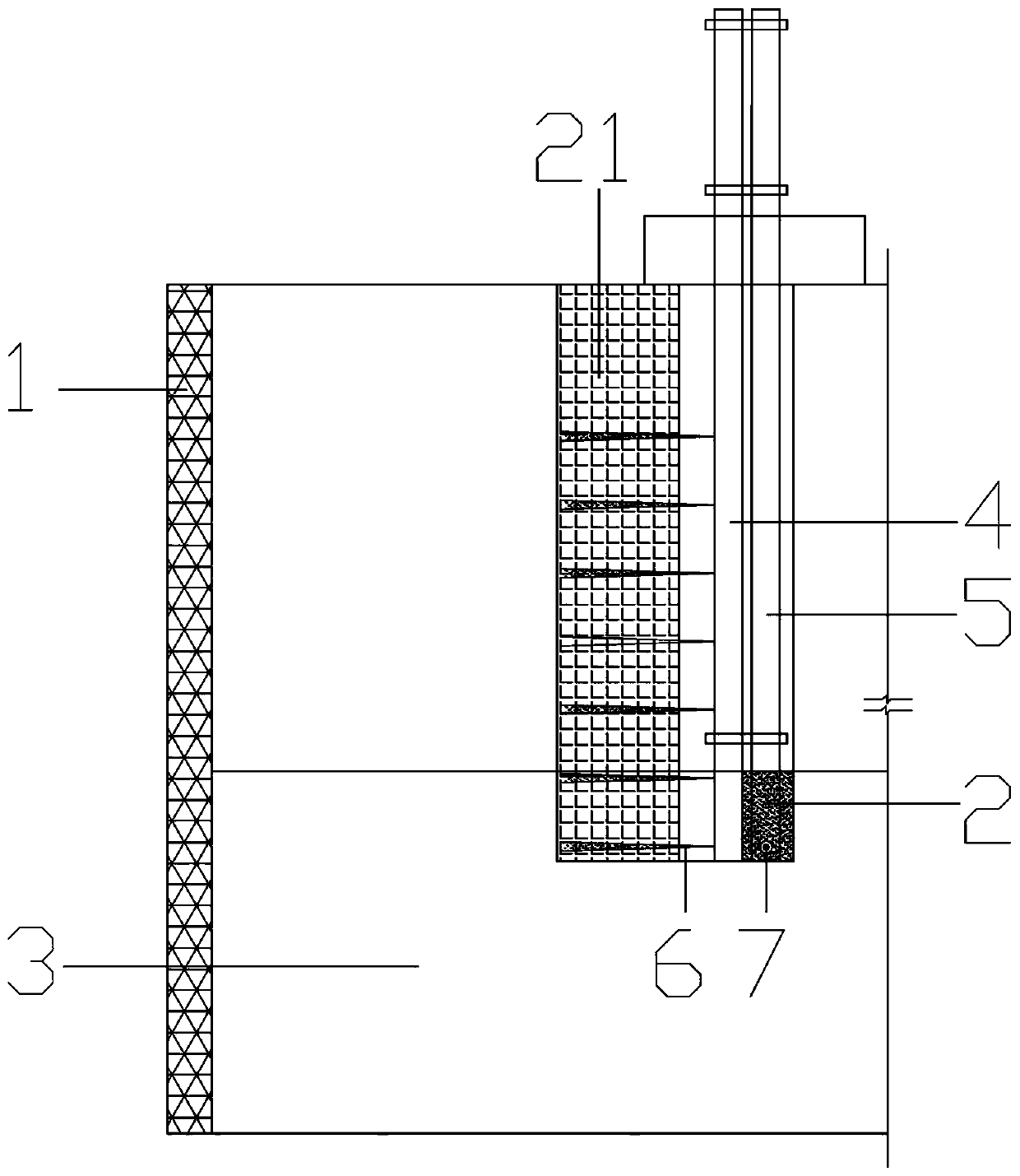

Construction device for floor support with ribbed trough

A technology of construction equipment and ground support, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., which can solve the problems of frequent machine movement, low work efficiency, and impact on efficiency, and achieve convenience Improvement in speed and speed, low reinforcement cost and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Step 1: Laying out wires on site, forming holes manually, setting up guide rails and leveling them for positioning, and assembling slot propellers and ground support formers at the same time.

[0057] Step 2: Using pile holes or artificial holes, place the lower end of the grooving propeller and the ground support former in the hole, install the upper end on the guide rail and assemble it with the conventional power device and transmission device; put the grooving propeller and ground support The strut former is connected with a high pressure pump.

[0058] Step 3: Start the high-pressure pump, start pumping high-pressure water, gas or cement slurry, then start the conventional power plant, start running, and drive the equipment to move horizontally while reciprocating up and down.

[0059] Part 4: The construction equipment for floor support with rib grooves completes the construction of a floor support, lifts the equipment with a crane, and starts the construction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com