Workpiece table device and immersive lithographic device

A technology of workpiece table and edge position, which is applied in the field of lithography machine and can solve problems such as thermal deformation of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

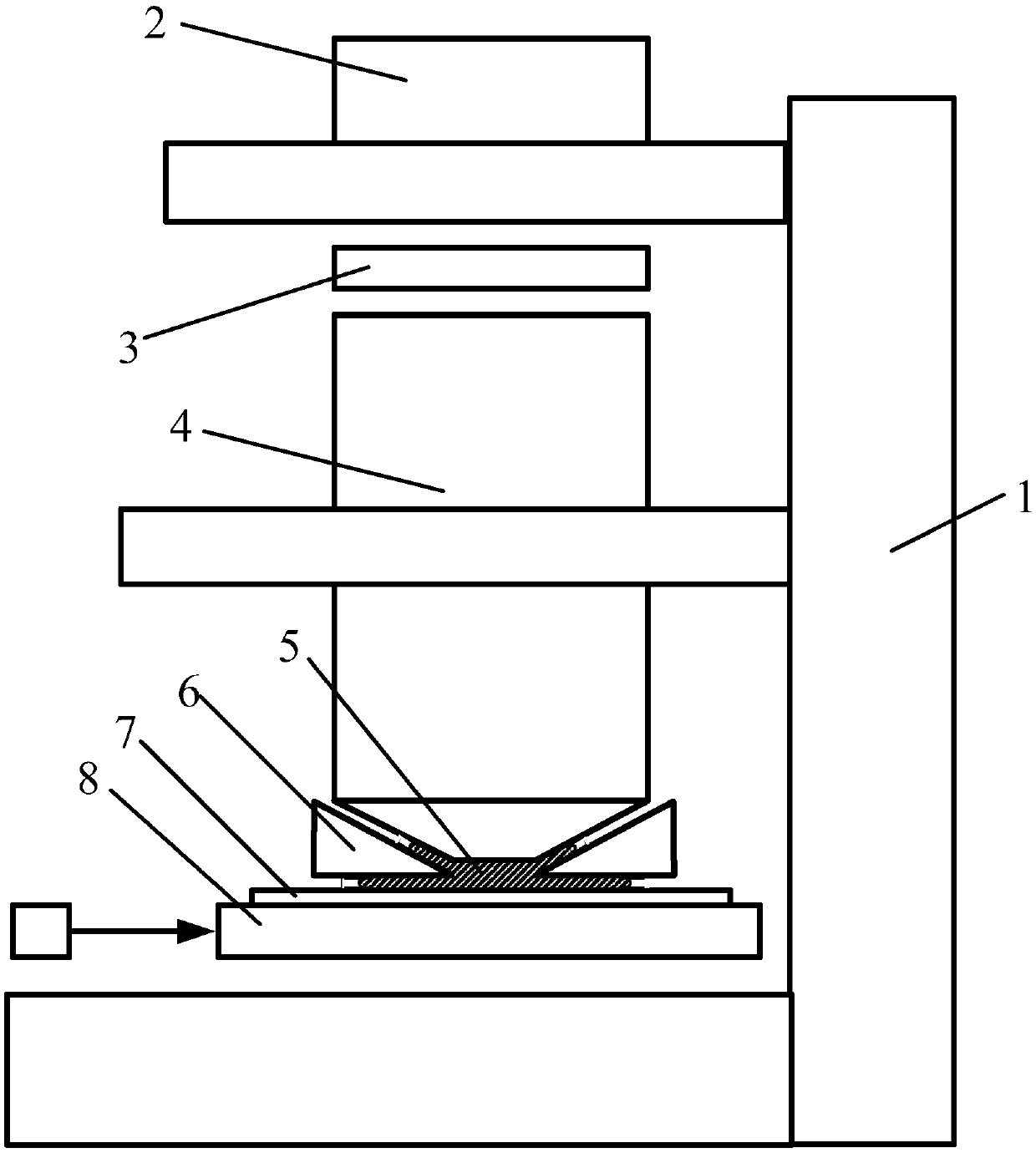

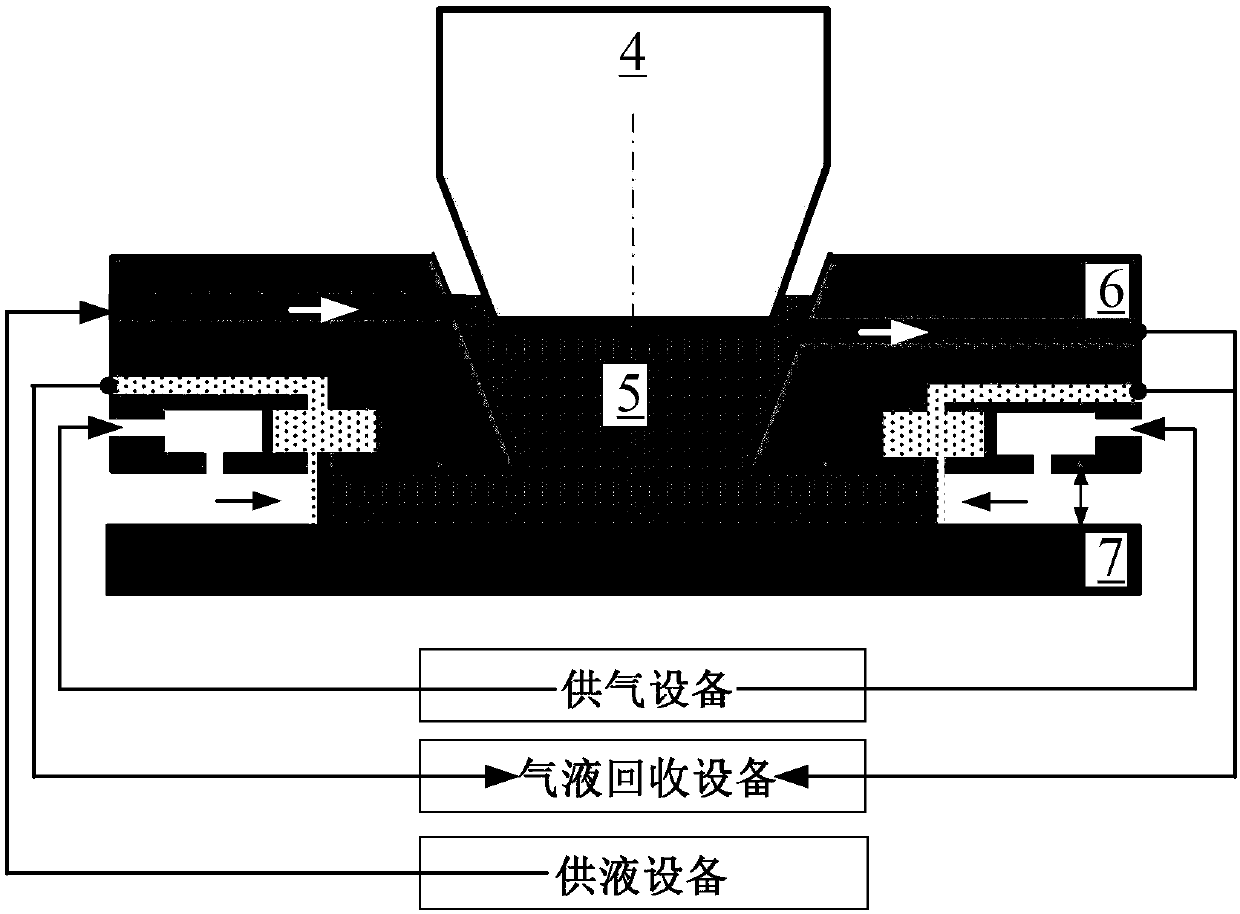

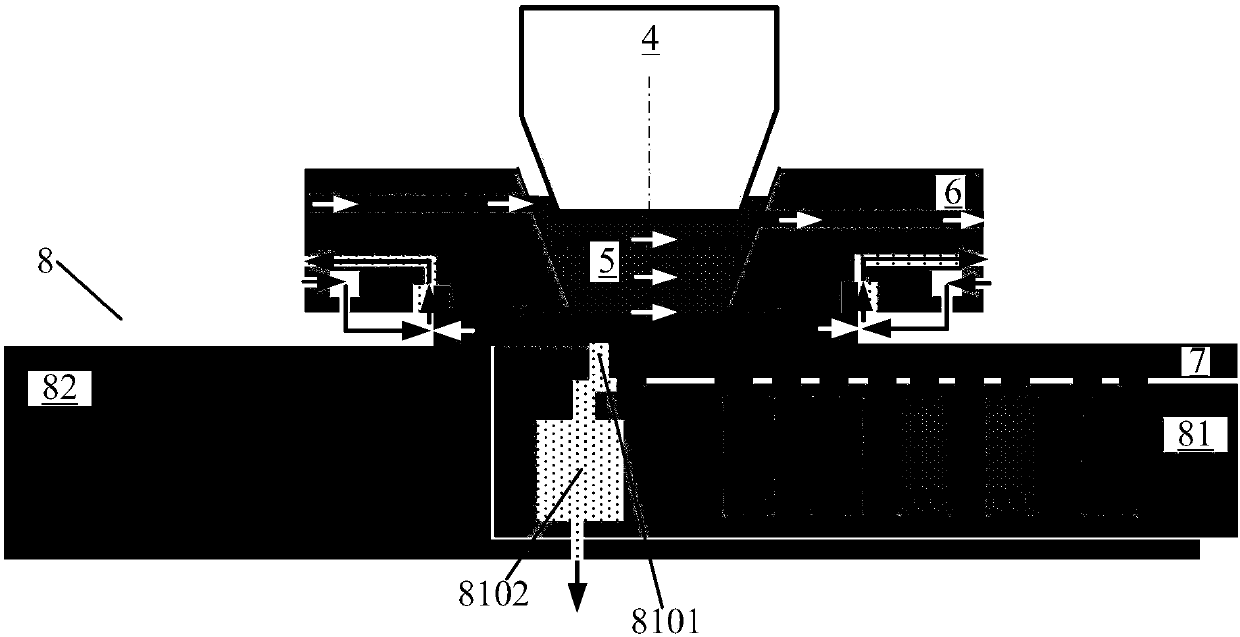

[0048] like Figure 4-9 As shown, the present invention provides a workpiece table device, including: a workpiece table unit 8, an edge gas-liquid recovery unit, a heat isolation unit and a heat external introduction unit, and the edge gas-liquid recovery unit is arranged around the workpiece table unit 8, the heat isolation unit is arranged around the inside and / or outside of the edge gas-liquid recovery unit, and the heat external introduction unit is used to extract the energy at the edge gas-liquid recovery unit to The workpiece table unit 8 is outside.

[0049] Wherein, the edge gas-liquid recovery unit is annularly arranged at the edge position in the workpiece table unit, the edge gas-liquid recovery unit includes a gas-liquid recovery cavity 8102, and the workpiece table unit 8 includes a workpiece table body 81 and Work table base 82.

[0050] The heat isolation unit is used to prevent the refrigeration power in the edge gas-liquid recovery unit from “leaking” to ot...

Embodiment 2

[0061] Please refer to Figure 11 and Figure 12 , in this embodiment, the heat diffusion mechanism 8107 is located at the bottom of the workpiece table base 82 . That is to say, the heat diffusion mechanism 8107 can be designed to be close to the workpiece table base 82 , or directly have a certain distance from the workpiece table base 82 , so as to improve the heat dissipation capability and further reduce the temperature influence on the workpiece table base 82 . The heat isolation unit is used to prevent the cooling power in the gas-liquid recovery chamber 8102 from “leaking” into the workpiece table base 82 , which is beneficial to improve the overall temperature uniformity of the wafer table base 82 .

Embodiment 3

[0063] In this embodiment, a heat diffusion mechanism is provided at the bottom of the workpiece table base 82 and the bottom of the workpiece table body 81 at the same time, that is, the heat diffusion mechanism includes a first heat diffusion mechanism arranged at the bottom of the workpiece table body 81 and a first heat diffusion mechanism arranged at the bottom of the workpiece table body 81. The second heat diffusion mechanism at the bottom of the workpiece table base 82 . The first heat diffusion mechanism and the second heat diffusion mechanism may be connected to the heat transfer mechanism 8106 respectively. A connection structure capable of realizing heat transfer may be provided between the first heat diffusion mechanism and the second heat diffusion mechanism, and the connection structure may be a part of the heat transfer mechanism 8106 or an independent structure. Setting the first heat diffusion mechanism and the second heat diffusion mechanism at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com