Immersion type liquid-cooled cabinet

An immersed, liquid-cooled technology, used in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc., can solve the problems of staying, unsatisfactory heat dissipation and cooling effect, etc., to reduce consumption and facilitate operation and maintenance. , Improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

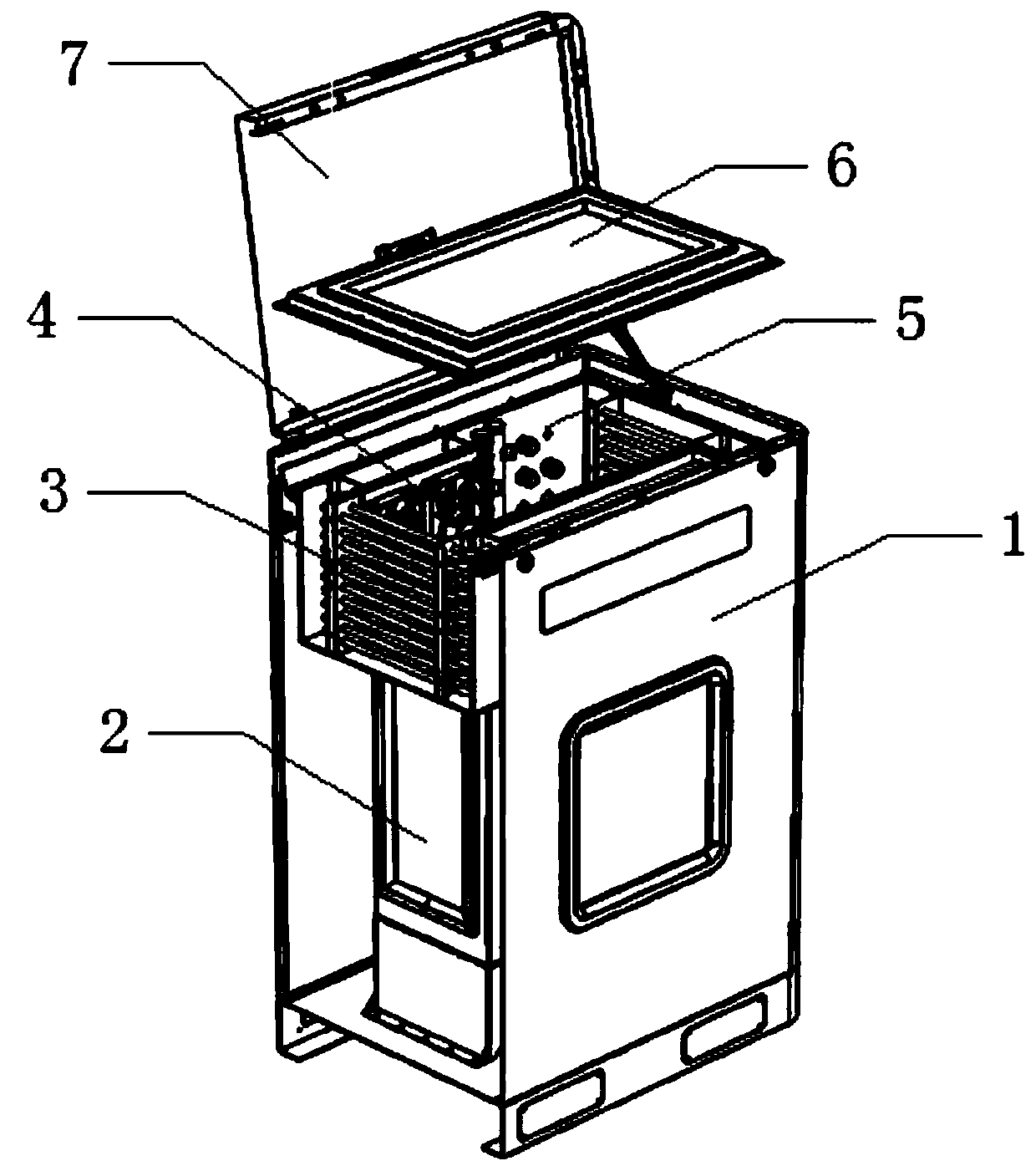

[0015] Such as figure 1 As shown, the submerged liquid-cooled cabinet of this embodiment includes an outer box 1 and an inner box 2, the inner box 2 is fixed inside the outer box 1, the inner box 2 is filled with a non-conductive liquid, and the liquid is immersed inside to generate heat Components and propeller devices, above the liquid level, on the inner wall of the inner box 2, the condenser tube group 3, fan assembly 4 and electrical accessories are installed through the interface 5, the top of the inner box 2 is provided with a removable sealing cover 6, and the top of the outer box 1 A reversible upper cover 7 is set. The top of the inner box 2 is equipped with a detachable sealing cover 6 with 8 to 16 flange holes around it, which are screwed and fixed with the inner box 2. The detachable sealing cover 6 is provided with a viewing window, which is convenient for observing the inner workings of the inner box 2. In this case, the inside of the inner box body 2 is a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com