Film mulching machine for garlic sprouts

A technology of laminating machine and garlic seedlings, which is applied in the agricultural field, can solve the problems of poor lamination quality, air generated by the film, time-consuming and labor-intensive, etc., and achieve the effects of improving lamination quality, preventing inflation and high delivery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

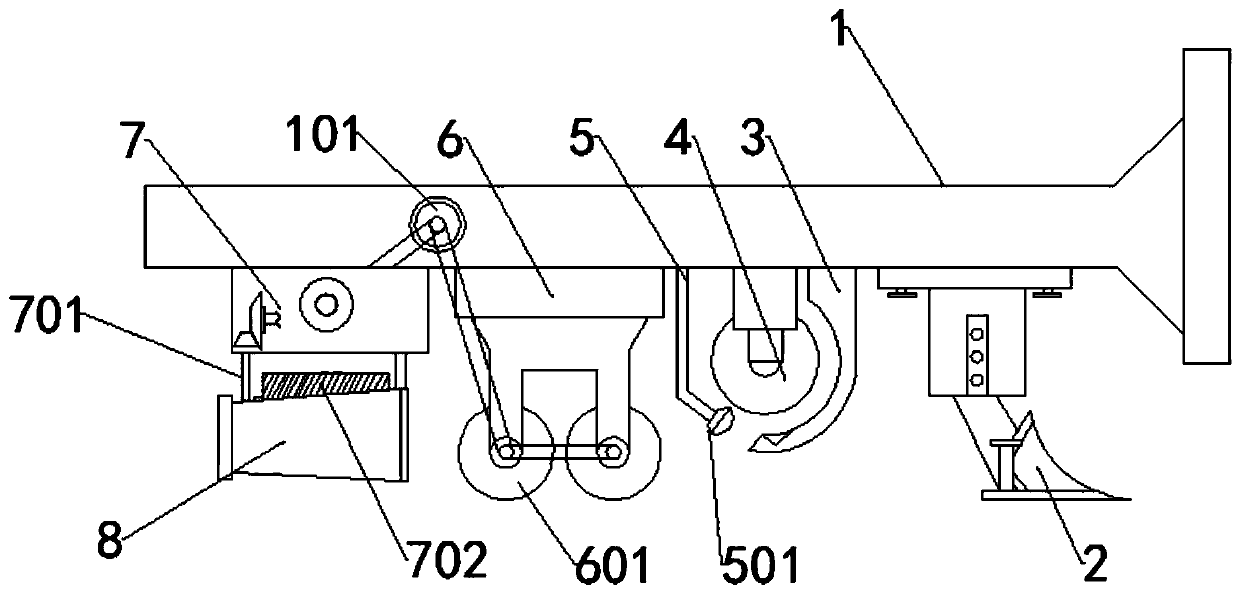

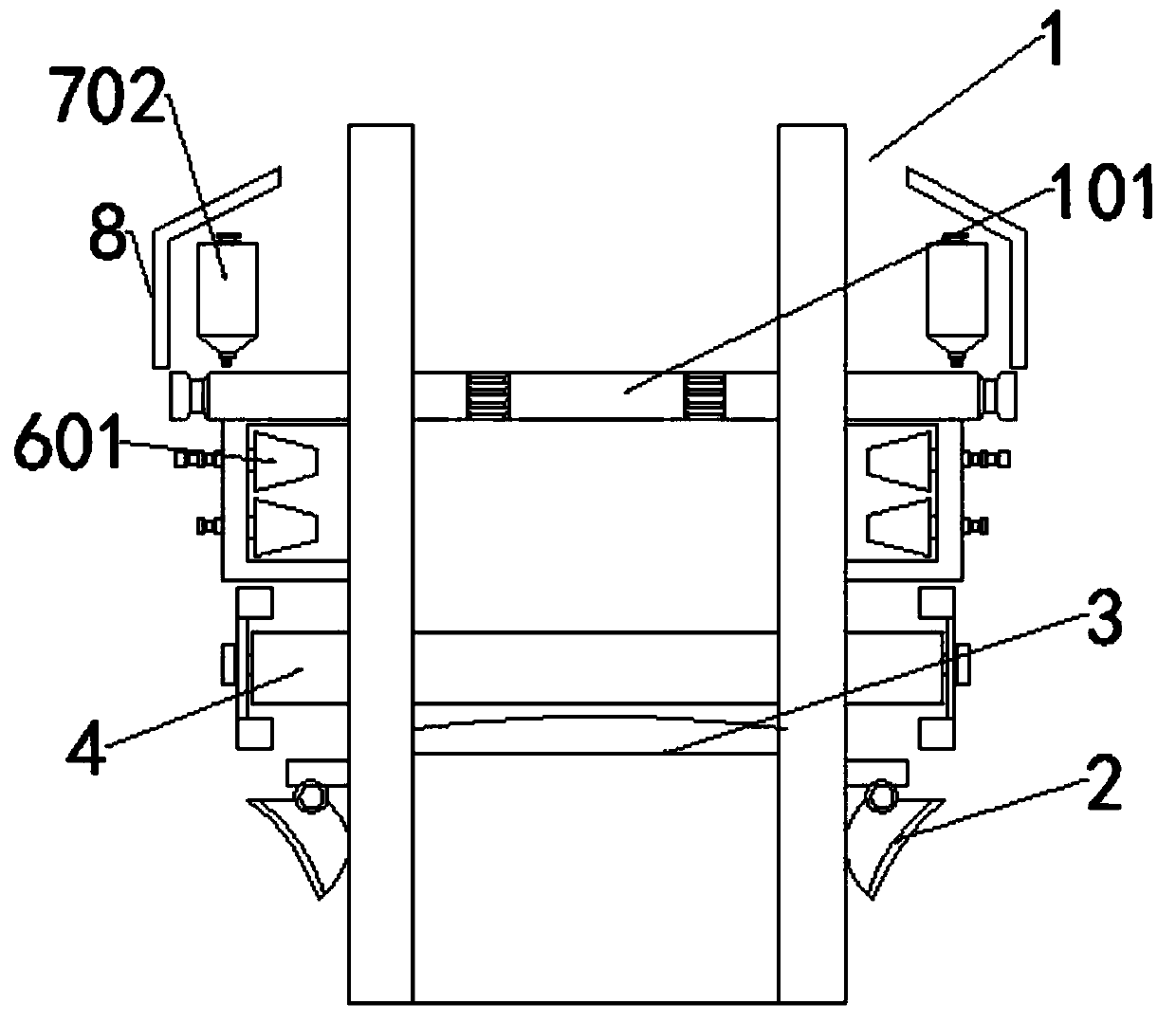

[0031] as attached figure 1 to attach Image 6 Shown:

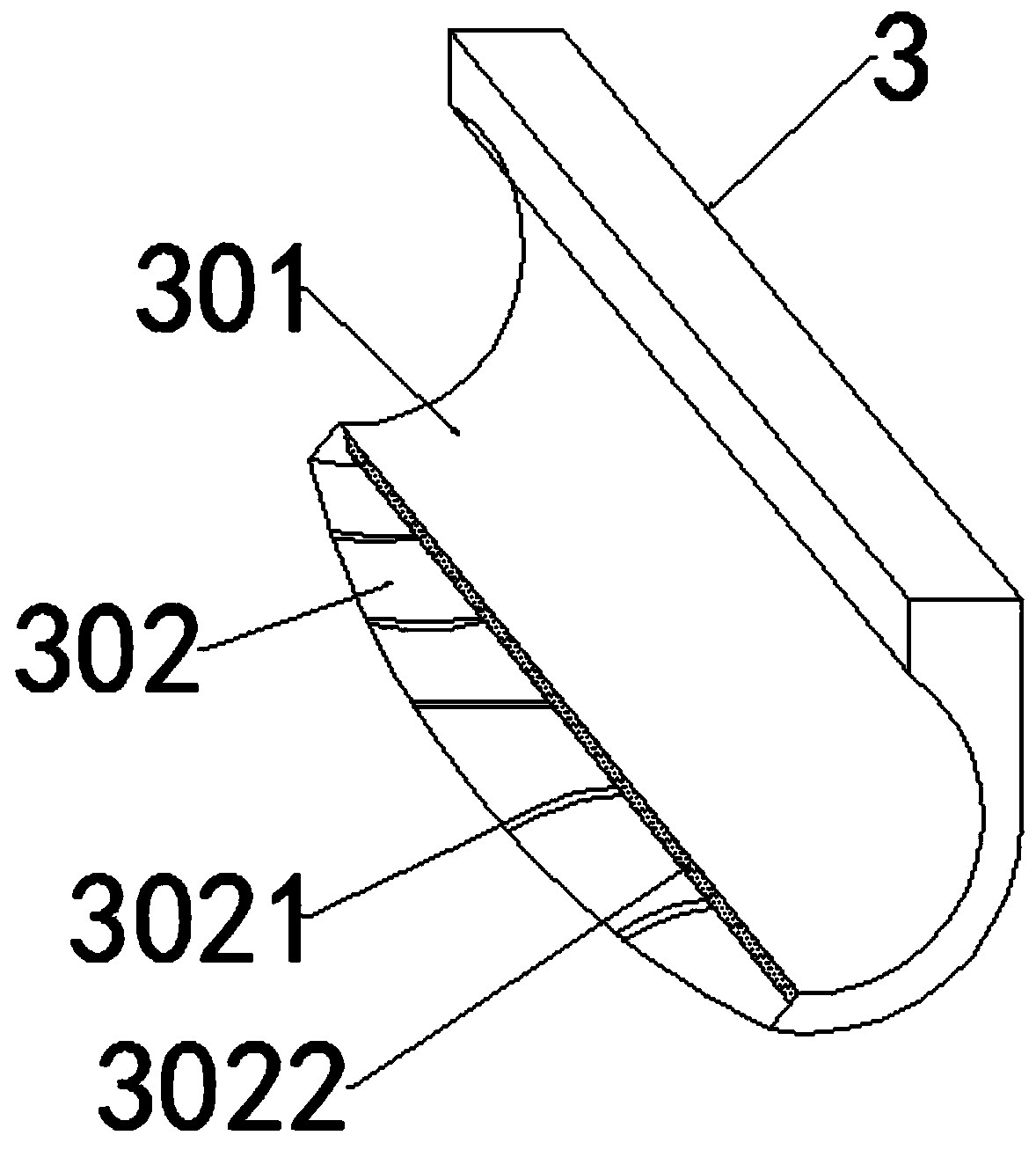

[0032] The invention provides a garlic seedling laminating machine, which includes a connecting truss 1, a plow 2, an induced draft fan 3, a thermal insulation film roll 4, a support rod 5, a linkage frame 6, a right-angle drive 7, and a deflector 8 , spline shaft 101, hollow concave plate 301, air inlet 302, guide groove 3021, convex plate 3022, heating plate 501, auxiliary roller 601, linkage rod 701, soil covering wheel 702 and guide tooth 7021; From one side to the other side, a plow 2, an induced draft fan 3, a support rod 5, a linkage frame 6, and a right-angle drive 7 are fixedly connected in sequence, and the heat preservation film roll 4 is located between the induced draft fan 3 and the support rod 5, and 4 and the connecting truss 1 are rotationally connected by connecting bolts. A spline shaft 101 is provided through the inside of the connecting truss 1. A hollow concave plate 301 is nested under the induced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com