Apparatus for preparing diamond coating in inner bores of wire-drawing dies

A diamond coating and wire drawing die technology is applied in metal material coating process, coating, gaseous chemical plating, etc. The effect of uniform deposition of coatings and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

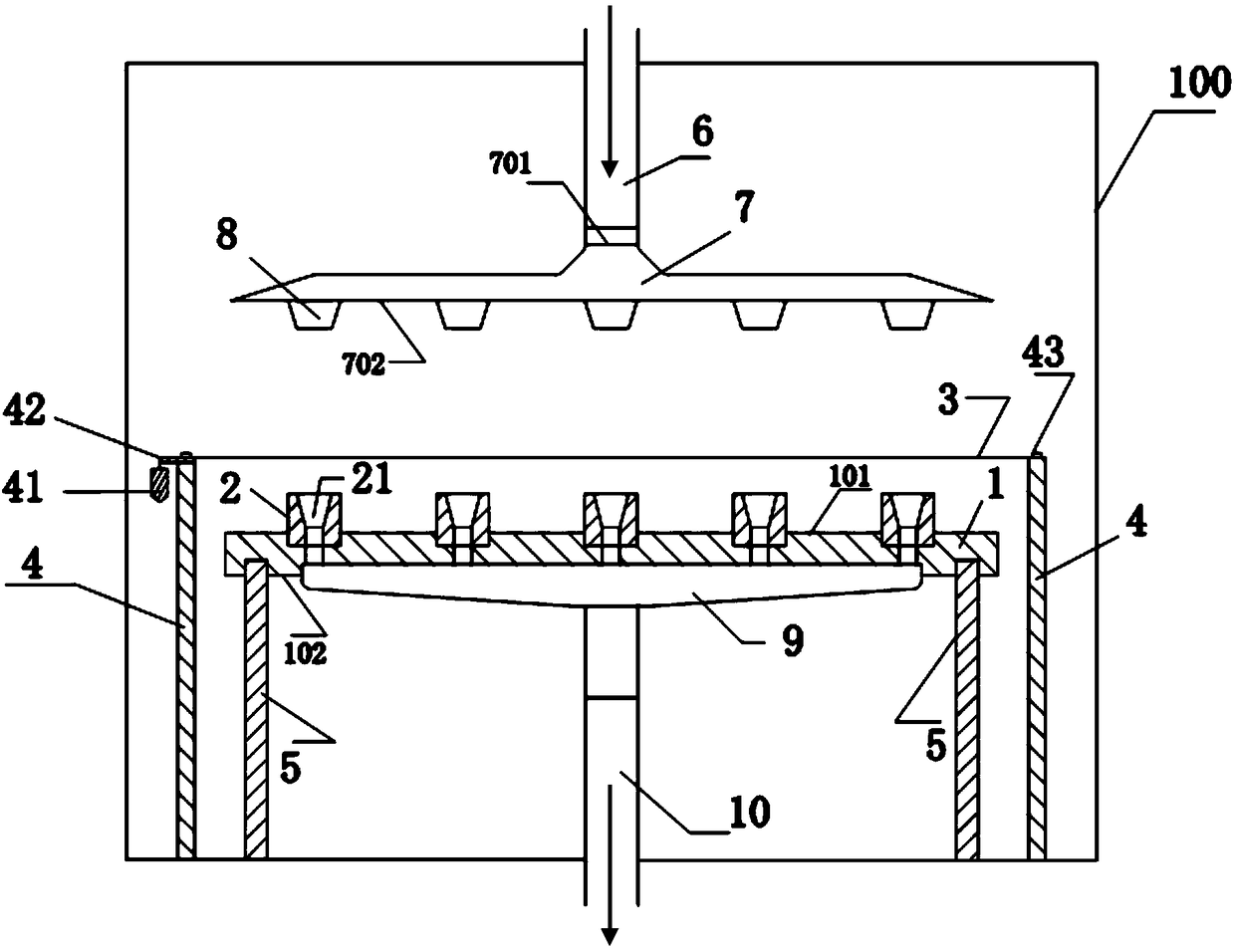

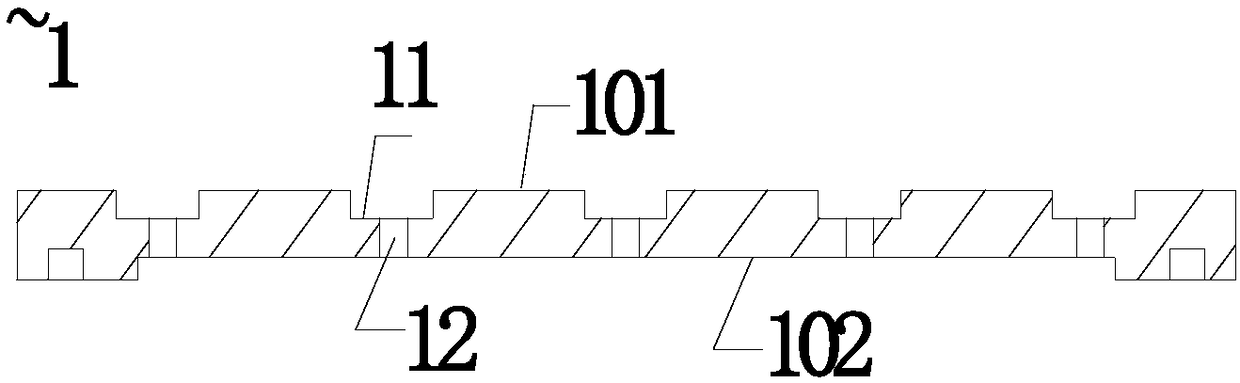

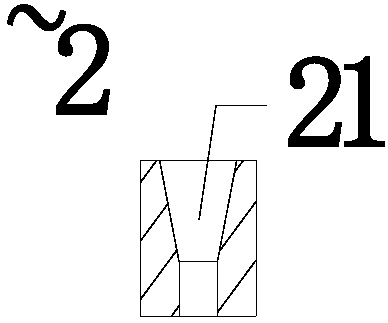

[0024] Please also refer to Figure 1-Figure 4 , is a schematic structural diagram of a device for preparing a diamond coating on the inner hole of a wire drawing die provided by a preferred embodiment of the present invention. The device includes a vacuum chamber 100 , and a sample stage 1 , a drawing die 2 , and a hot wire 3 arranged in the vacuum chamber 100 .

[0025] A heating wire 3 is arranged horizontally above the sample stage 1 , and two ends of the heating wire 3 are respectively connected to electrode columns 4 . The two ends of the heating wire are respectively connected to the electrode column to realize the support of the heating wire, and provide voltage and current for the heating wire to make the heating wire generate heat, and complete the thermal ionizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com