Temperature-gradient rising sterilization device for crayfishes and using method of device

A sterilizing device and segmental heating technology, applied in chemical instruments and methods, cleaning methods and utensils, applications, etc., can solve problems such as crayfish shell attachment, unfavorable conveyor belt cleaning, easy to damage crayfish meat quality, etc., to achieve convenient cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

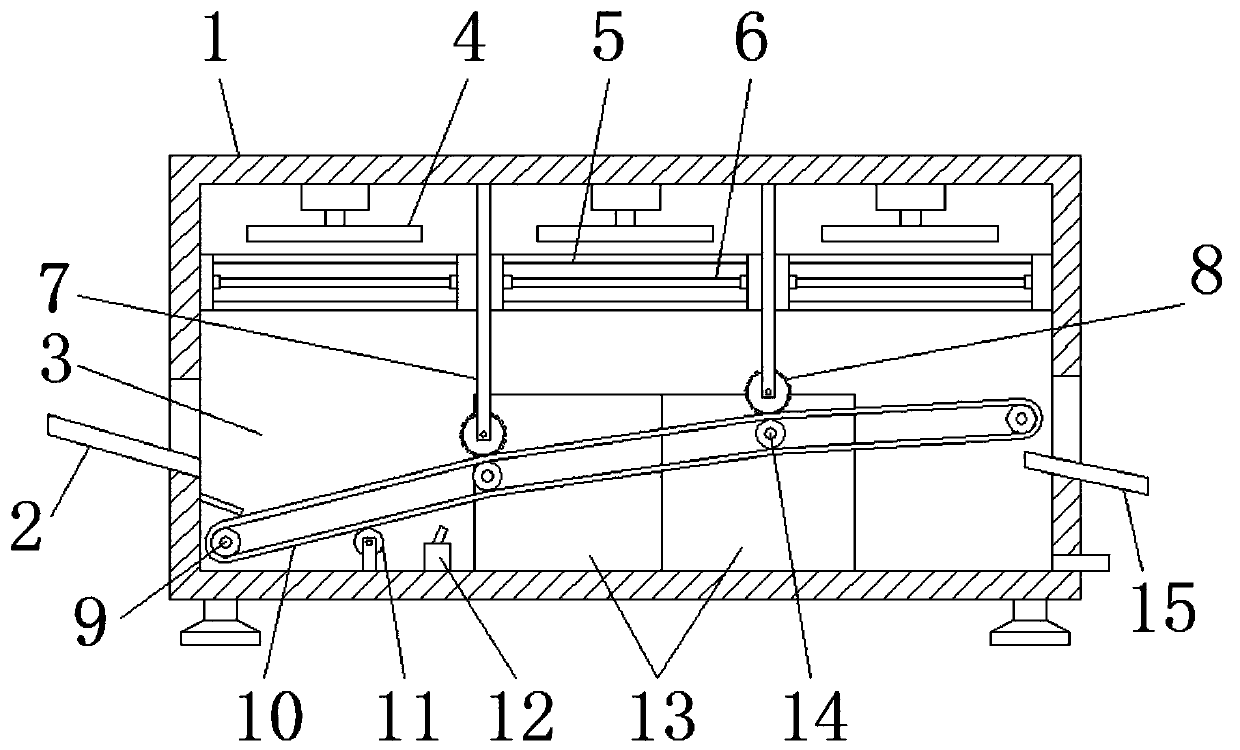

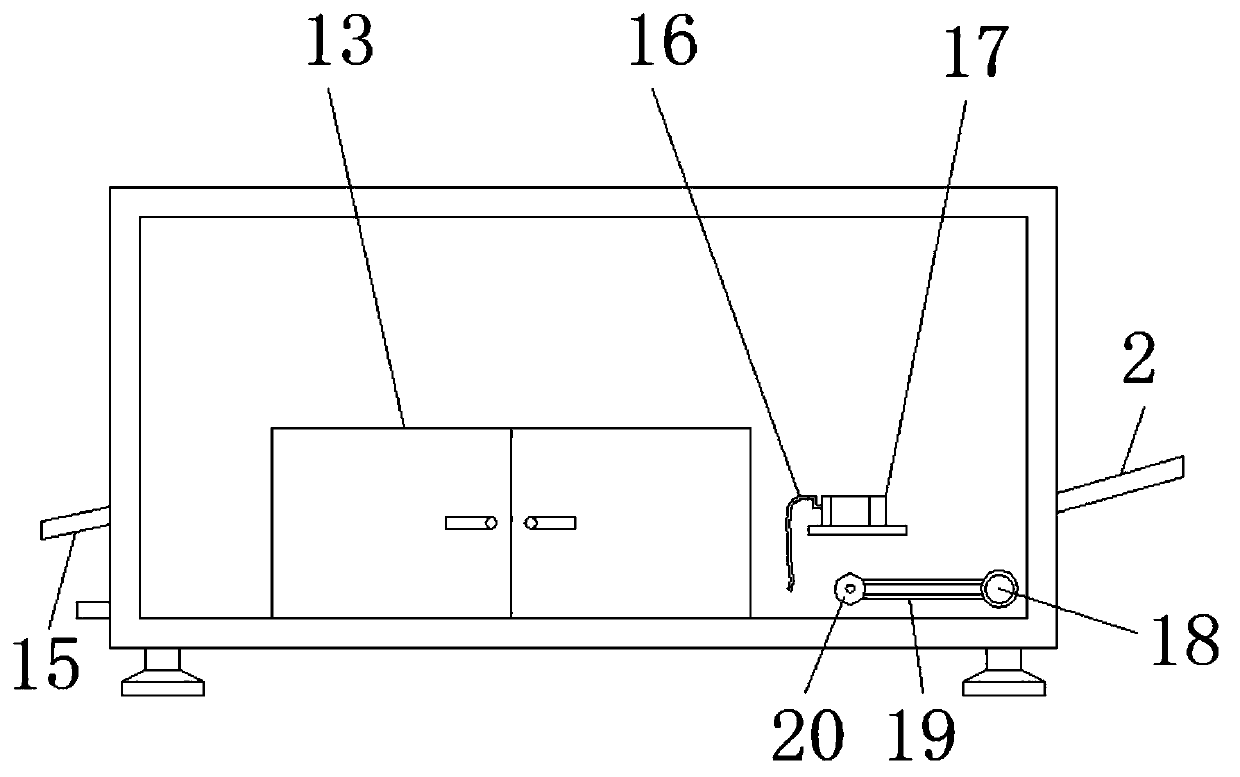

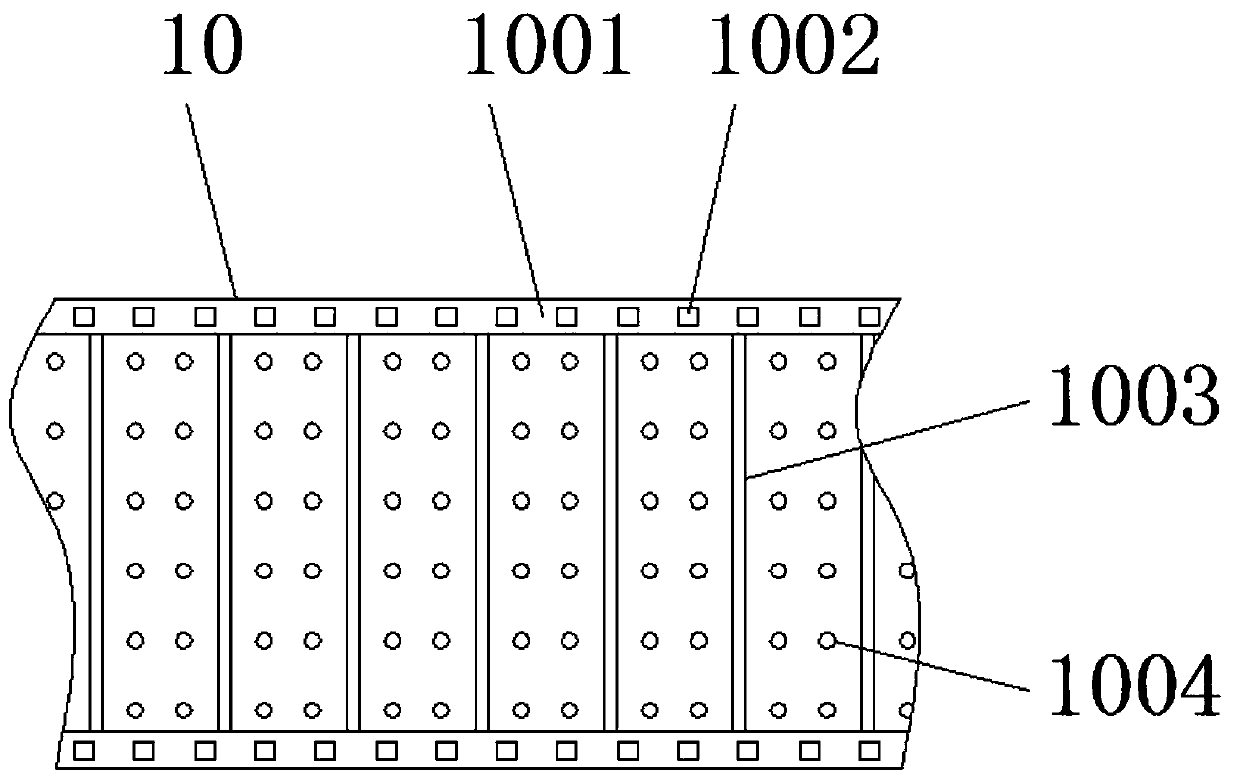

[0037] see Figure 1-8, the present invention provides a technical solution: a crayfish segmental heating sterilization device, including a sterilization device main body 1, a feed trough 2, a sterilization bin 3, a hot air blower 4, a protective cover 5, an ultraviolet lamp 6, and a partition plate 7 , gear plate 8, driving roller 9, conveyor belt 10, edge protection 1001, tooth groove 1002, blocking strip 1003, water filter hole 1004, cleaning roller brush 11, main water pipe 12, cleaning door 13, driven roller 14, discharge chute 15. Hose 16, pressurized water pump 17, servo motor 18, belt 19, pulley 20, bracket 21, rotating rod 22, moving blade 23, water spray head 24, protective net 25 and connection block 26, sterilizing device main body 1 A feeding trou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com