Method for synergetic stabilization and solidification of ardealite and phosphorite flotation tailings

A technology of flotation tailings and solidification method, which is applied in the direction of solid waste removal, etc., can solve the problems of high pH value and high cost, and achieve the effects of simple operation, reduced environmental pressure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

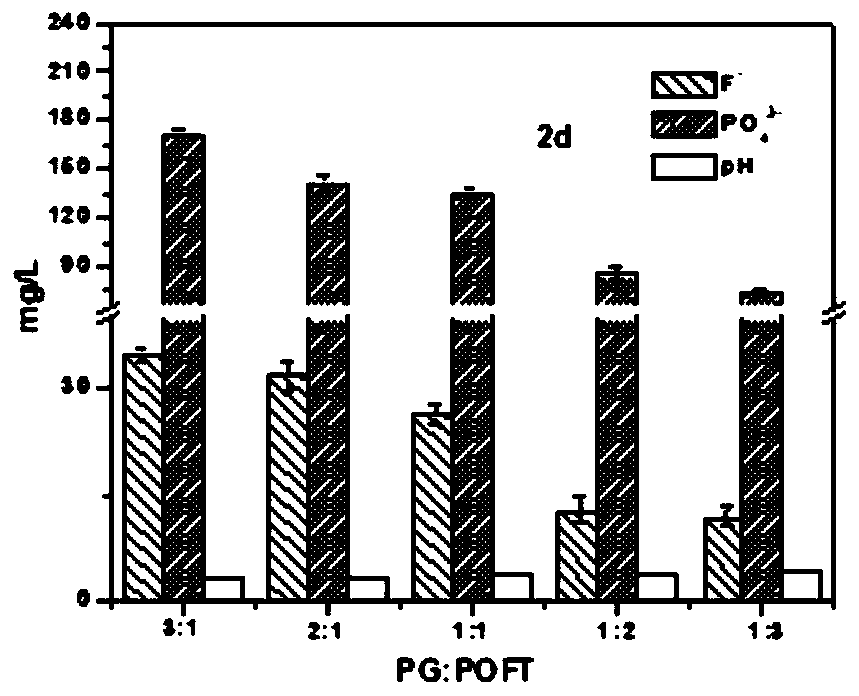

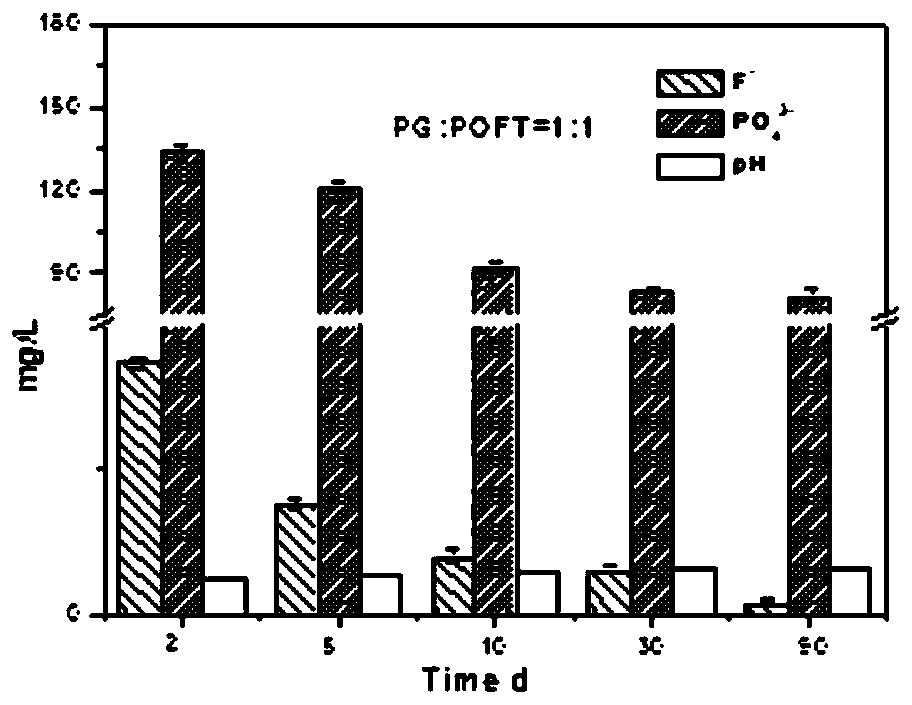

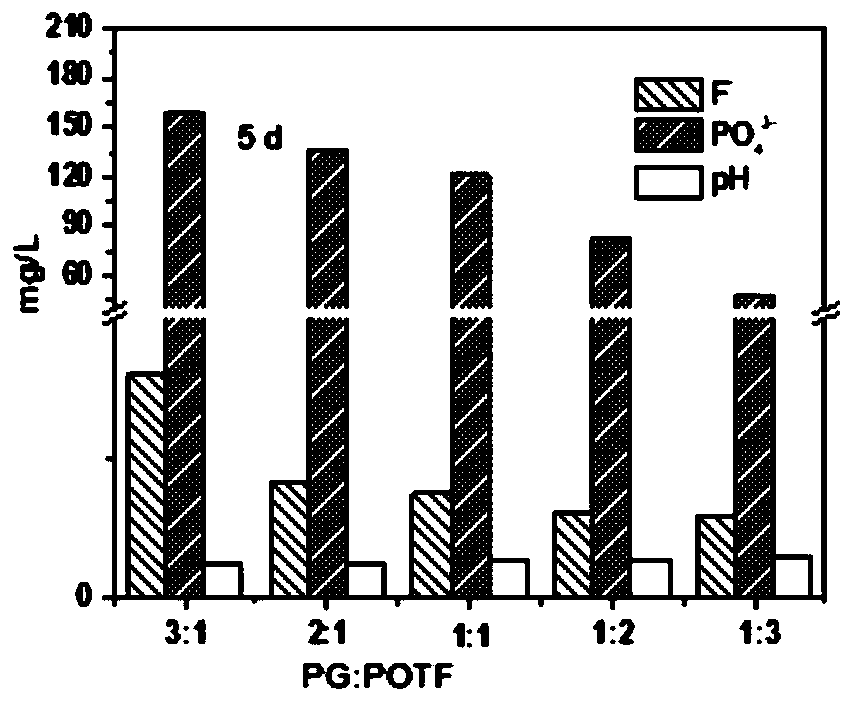

[0040] 1. The mass ratio of phosphogypsum and phosphate rock flotation tailings compared to PO 4 3- and F - Effect of stable curing

[0041] At room temperature, mix the phosphogypsum and phosphate rock flotation tailings according to the mass ratio of 3:1, 2:1, 1:1, 1:2, and 1:3, respectively, and then stack and solidify at room temperature.

[0042] When the mass ratio of phosphogypsum to phosphate rock flotation tailings decreased from 3:1 to 1:3, the pH value of the stable solidification system increased from 3.4 to 4.1, and PO 4 3- , F - Concentration decreased.

[0043] Such as Figure 1-6 Shown: When phosphogypsum and phosphate rock flotation tailings are stably solidified for 2 days, the mass ratio is reduced from 3:1 to 1:3, PO in the leach solution 4 3- The concentration of F was reduced from 170.4mg / L to 74.0mg / L. - From 34.7mg / L to 11.82mg / L.

[0044] When the mass ratio of phosphogypsum to phosphate rock flotation tailings is 1:1, F in the leachate - an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com