Moving cutter assembly and crushing device

A technology of crushing device and knife assembly, applied in recycling technology, grain processing, mechanical material recycling, etc., can solve the problem of large power consumption of crushers, and achieve the effect of low noise and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

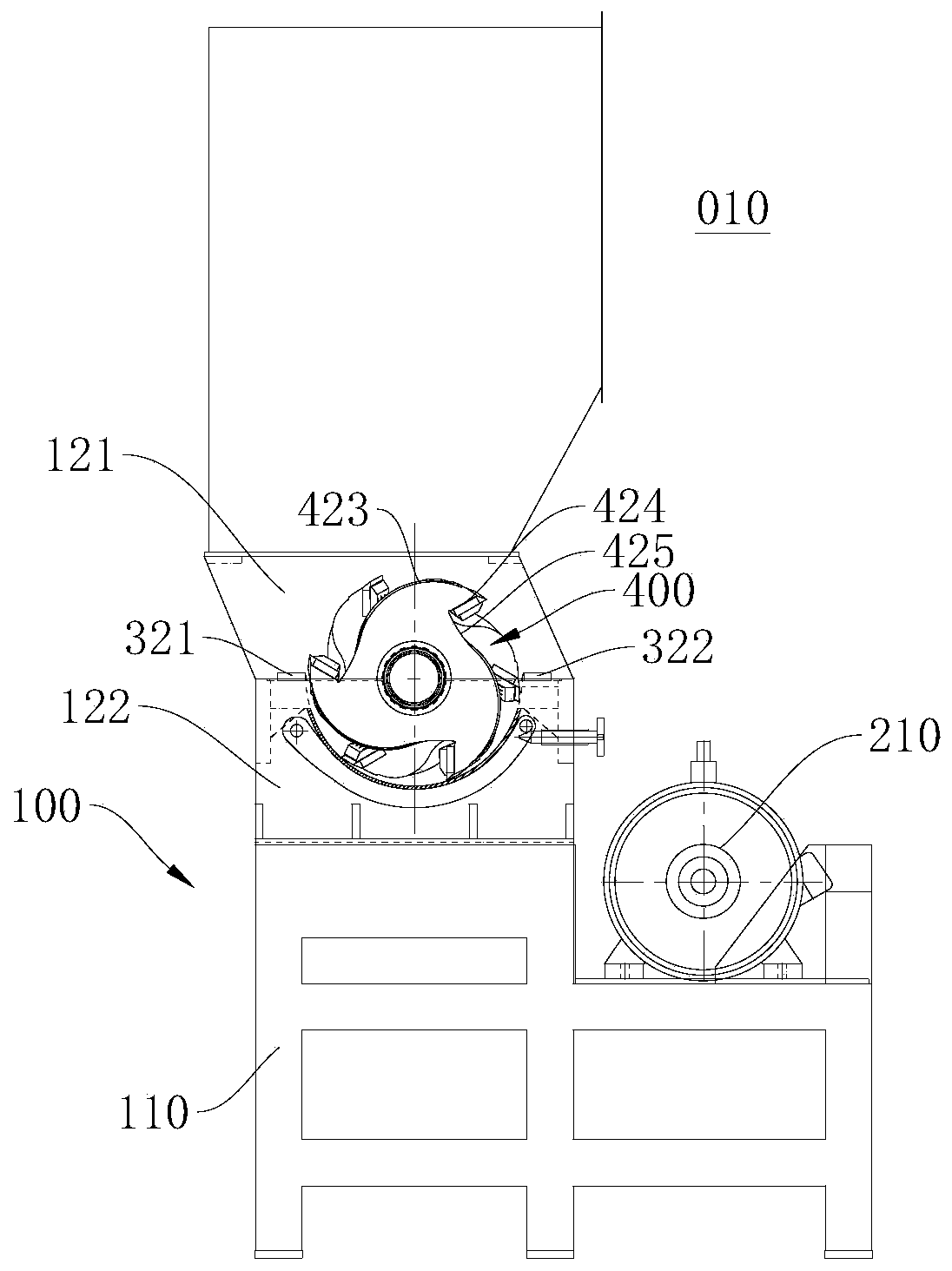

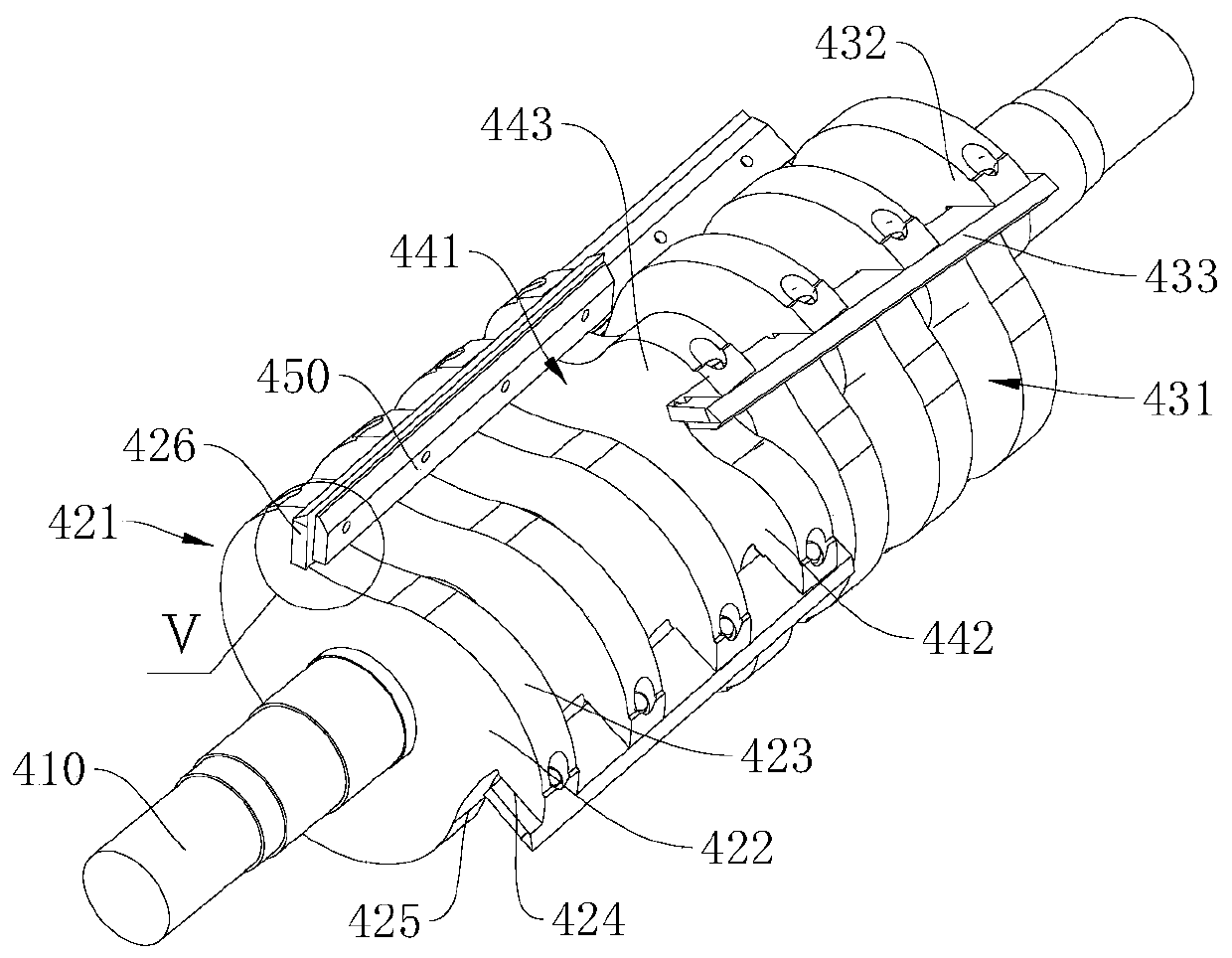

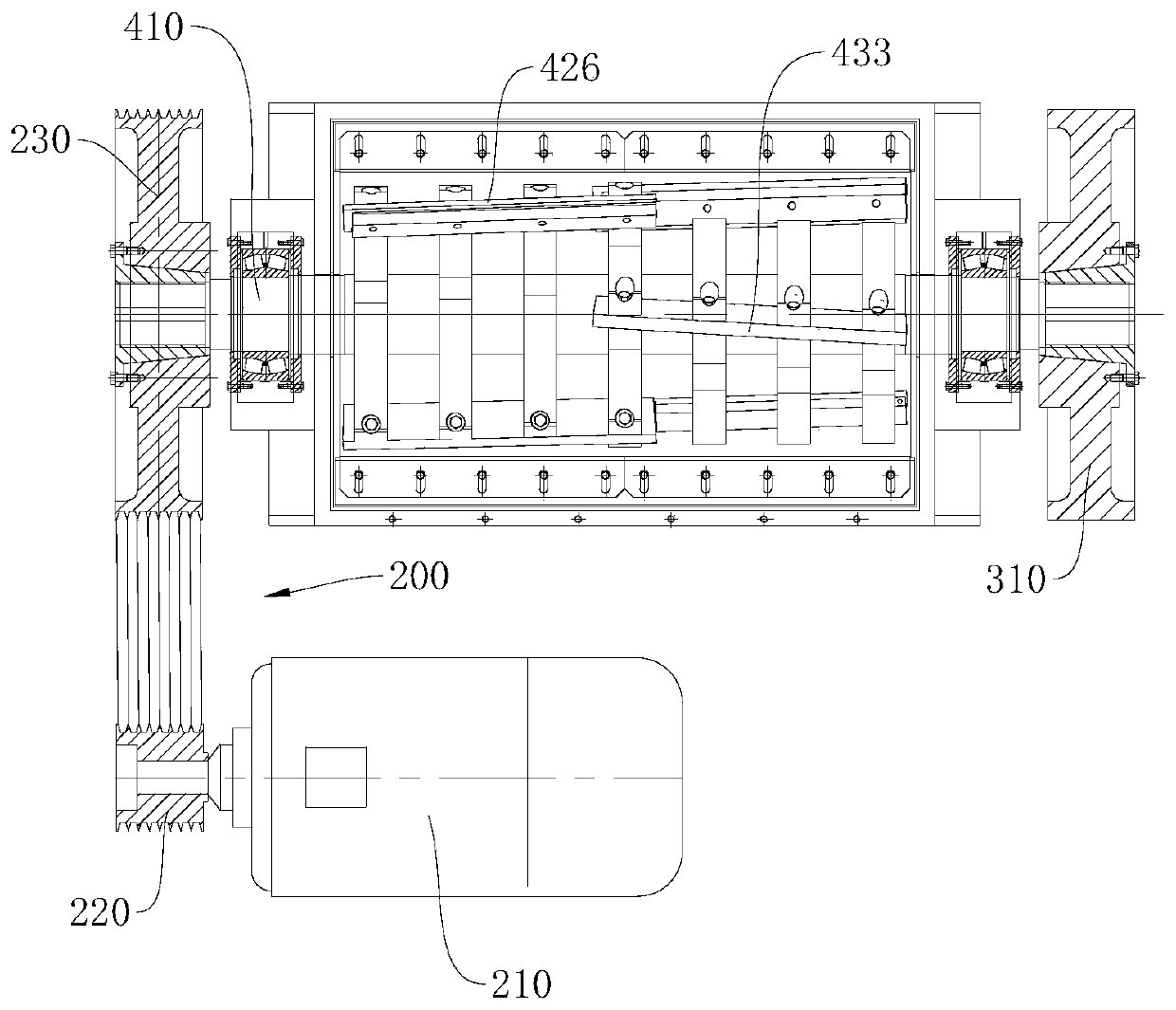

[0040] figure 1 It is a schematic diagram of the overall structure of the crushing device 010 provided in this embodiment, figure 2 This embodiment provides a schematic structural diagram of the movable knife assembly 400 in the crushing device 010 at a first viewing angle. Please refer to figure 1 with figure 2, this embodiment provides a crushing device 010 , which includes a frame 100 , a driving mechanism 200 and a moving knife assembly 400 . Both the driving mechanism 200 and the movable knife assembly 400 are arranged on the frame 100 , and the driving mechanism 200 is connected to the movable knife assembly 400 in transmission, and is used to drive the movable knife assembly 400 to rotate. The moving knife assembly 400 includes a main shaft 410, a first knife rest 421, a second knife rest 431, an intermediate knife rest 441, a first moving knife 426 and a second moving knife 433, the first knife rest 421, the middle knife rest 441 and the second The tool holders 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com