Material transfer device, loading equipment, discharge equipment and detection system

A transfer device and material technology, which is applied in the field of detection systems, can solve problems such as low efficiency, and achieve the effects of reducing costs, improving efficiency, and improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

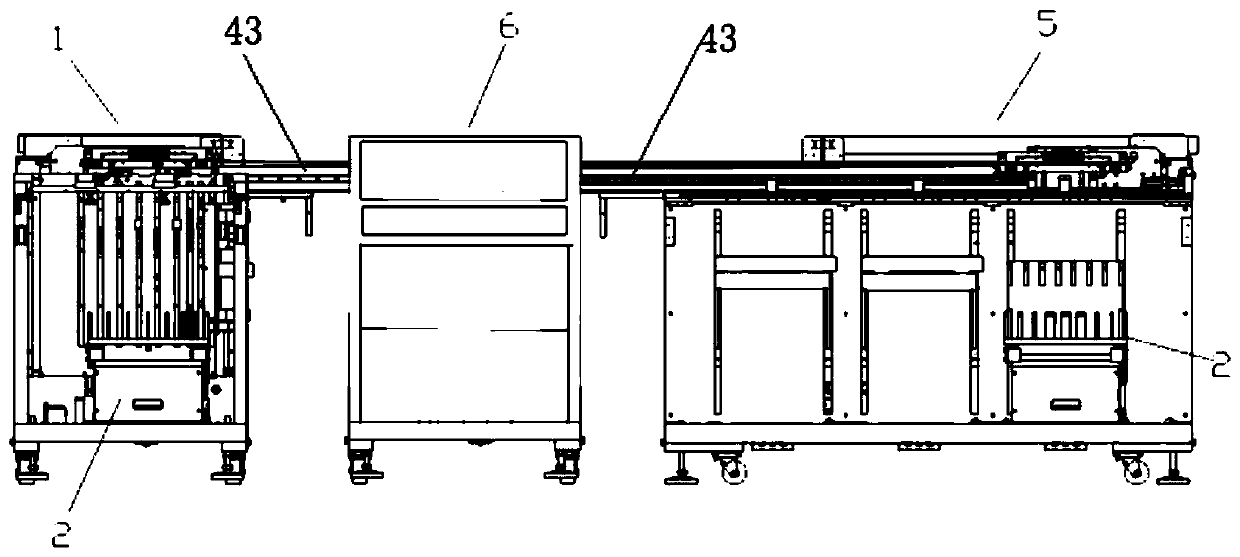

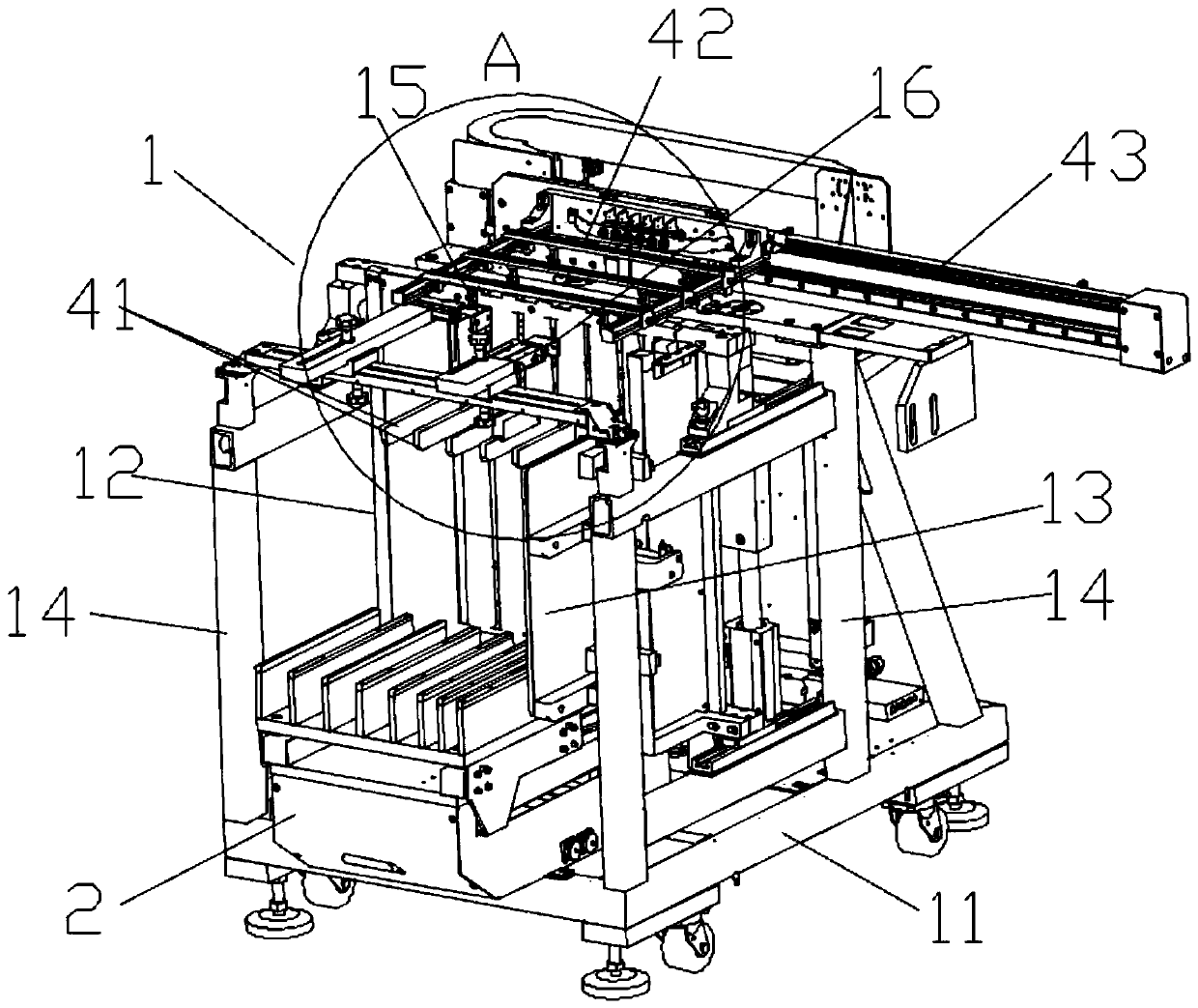

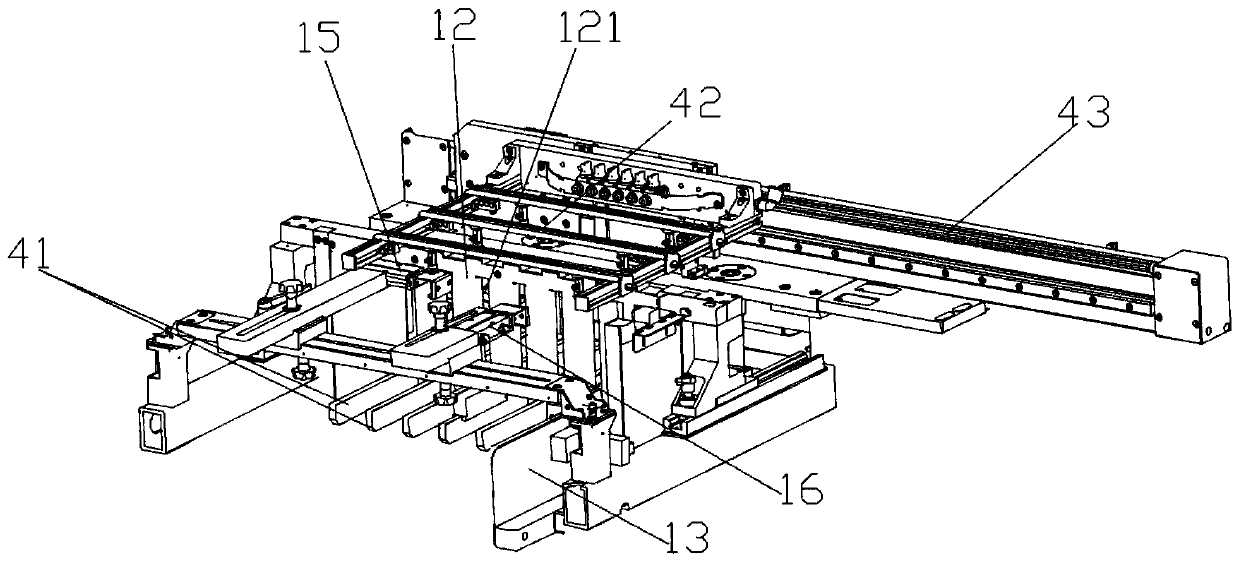

[0069] This embodiment describes a detection system, such as figure 1 As shown, it includes a feeding device 1, a discharging device 5 and a testing device 6, wherein the testing device 6 is connected and arranged between the feeding device 1 and the discharging device 5, as figure 1 The other end of the guide rail 43 in the shown feeding device 1 extends above the test platform in the test device 6 for transporting the material to the test platform, and one end of the guide rail 43 in the discharge device 5 also extends into the test platform. In the testing equipment 6, it is used to take out the material from the testing equipment 6 and transport it to the discharging equipment 5.

[0070] The materials in this embodiment are plate-shaped materials such as PCB boards, and of course other materials with fixed shapes can also be used. The testing equipment 6 in this embodiment is the on-off testing equipment of the PCB board.

[0071] The detection system in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com