A hoisting device with anti-rust function for ship maintenance

A technology for lifting equipment and functions, applied in the field of ship maintenance equipment, can solve the problems of reducing the safety of operators working at heights, reducing the safety of gantry cranes, reducing the practicability of gantry cranes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

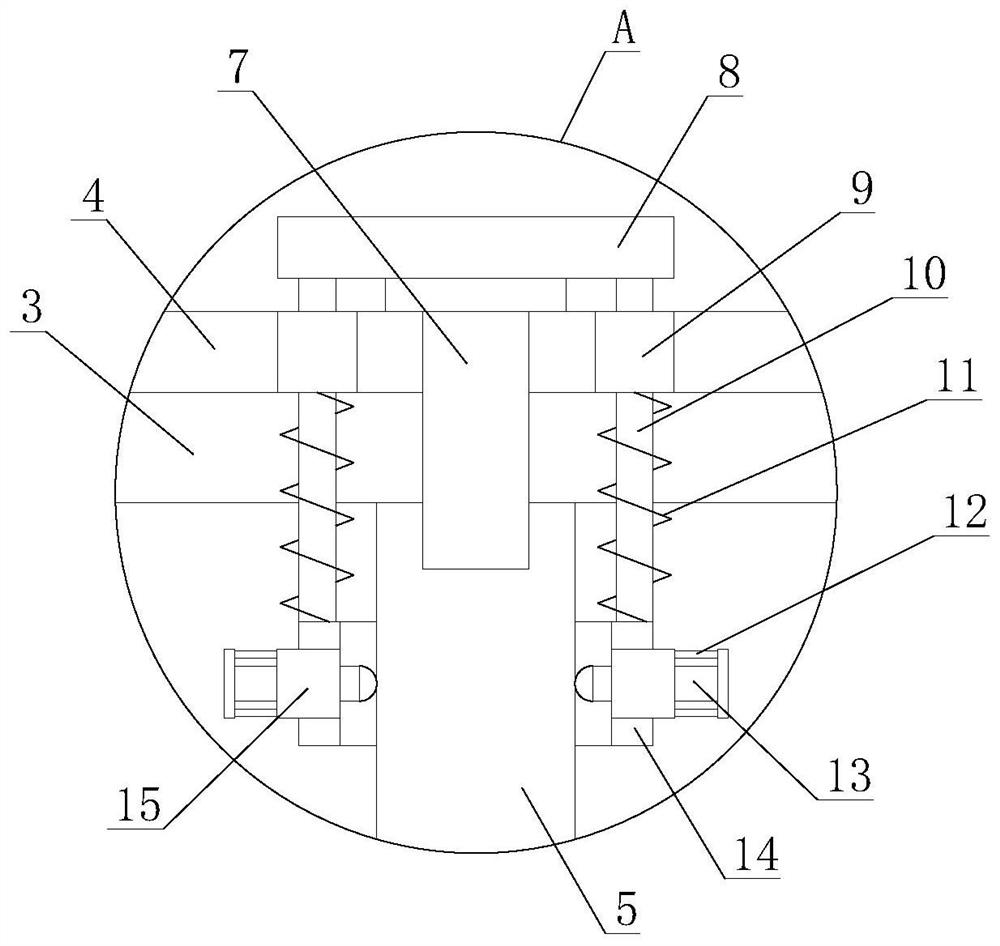

[0024] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

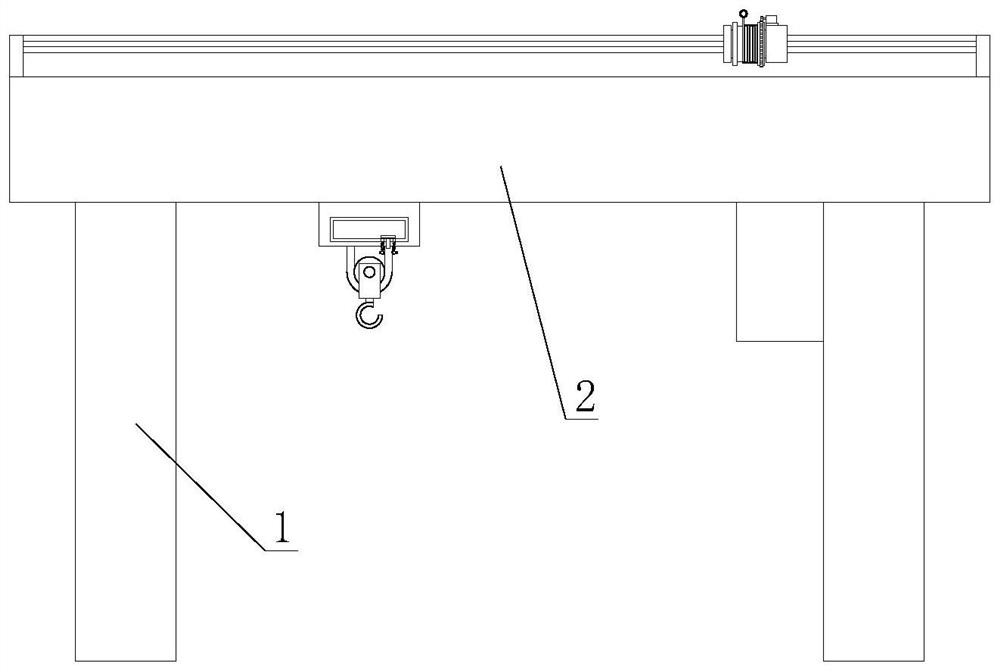

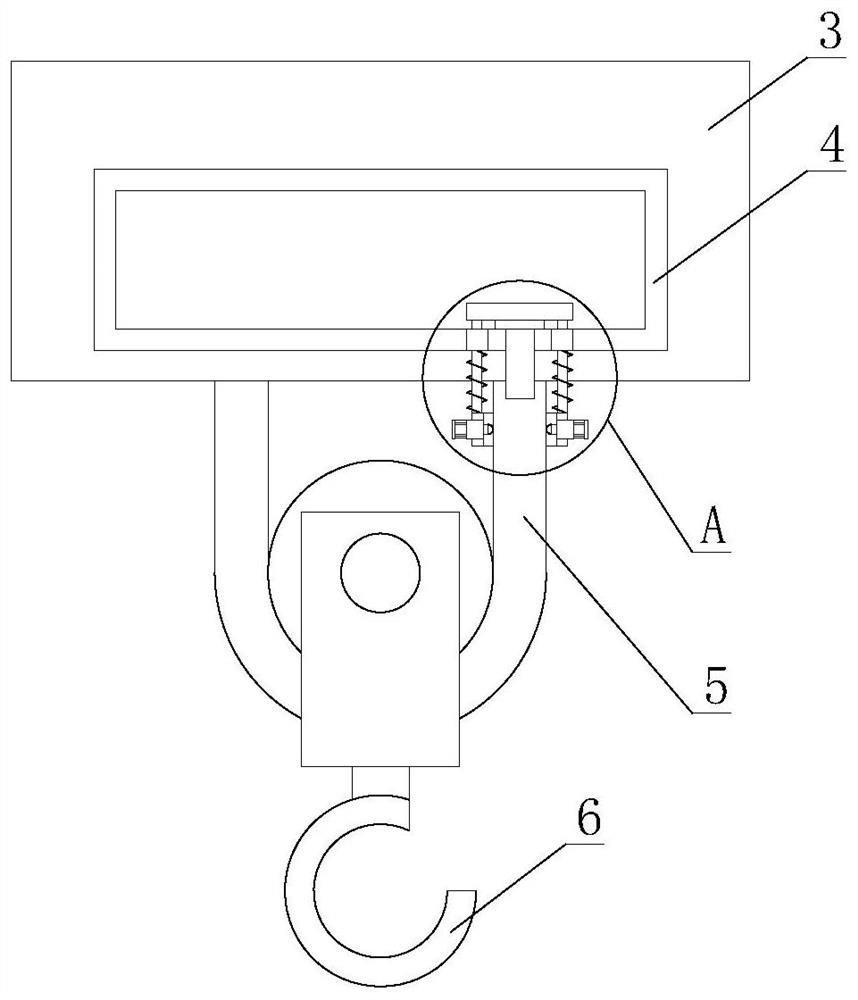

[0025] like figure 1 As shown, a hoisting device with anti-rust function for ship maintenance includes a main beam 2, a power unit 3, a wire rope 5, a hook 6 and two brackets 1, and the bracket 1 is arranged at one end of the main beam 2 , the power device 3 is arranged on the main beam 2, the hook 6 is connected with the power device 3 through the wire rope 5, and also includes a rust prevention mechanism and a protection mechanism, the protection mechanism is arranged on the main beam 2, the anti-rust mechanism The rust mechanism is arranged on the power unit 3;

[0026] The lubricating oil can be applied to the wire rope 5 through the anti-rust mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com