Method for preparing panel glass of washing machine

A panel glass and washing machine technology, applied in glass manufacturing equipment, other washing machines, glass tempering, etc., can solve the problems of insufficient temperature resistance and impact resistance of glass, inability to effectively guarantee glass size, difficulty in ensuring process effect, etc., to achieve Guarantee the follow-up process, improve temperature resistance, and smooth corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

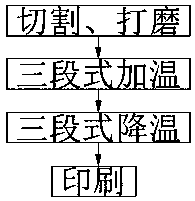

[0020] The washing machine panel glass preparation method comprises the following steps:

[0021] S1: Cutting and grinding: Cut the glass to the required size and use a laser grinder to grind the surroundings of the glass to smooth the surroundings of the glass. Laser grinding can effectively guarantee the size of the glass, and the edges and corners after grinding are smooth. Can effectively guarantee the follow-up process;

[0022] S2: Three-stage heating: Put the cut and polished glass into the tempering furnace for three-stage high-temperature tempering. The first stage is heated to 120°C and kept for 30 minutes, and the second stage is heated to 200°C. Keep it for 20 minutes, heat up to 260 degrees Celsius in the third stage, and keep it for 10 minutes;

[0023] S3: Three-stage cooling: Take out the glass after three-stage high-temperature tempering and put it into the cooling furnace for three-stage cooling. The first stage rapidly lowers the temperature to 200°C and ke...

Embodiment 2

[0026] The washing machine panel glass preparation method comprises the following steps:

[0027] S1: Cutting and grinding: Cut the glass to the required size and use a laser grinder to grind the surroundings of the glass to smooth the surroundings of the glass. Laser grinding can effectively guarantee the size of the glass, and the edges and corners after grinding are smooth. Can effectively guarantee the follow-up process;

[0028] S2: Three-stage heating: Put the cut and polished glass into the tempering furnace for three-stage high-temperature tempering. The first stage is heated to 160°C and kept for 35 minutes, and the second stage is heated to 220°C. Keep it for 23 minutes, heat up to 280 degrees Celsius in the third stage, and keep it for 13 minutes;

[0029] S3: Three-stage cooling: Take out the glass after three-stage high-temperature tempering and put it into the cooling furnace for three-stage cooling. The first stage rapidly lowers the temperature to 240°C and ke...

Embodiment 3

[0032] The washing machine panel glass preparation method comprises the following steps:

[0033] S1: Cutting and grinding: Cut the glass to the required size and use a laser grinder to grind the surroundings of the glass to smooth the surroundings of the glass. Laser grinding can effectively guarantee the size of the glass, and the edges and corners after grinding are smooth. Can effectively guarantee the follow-up process;

[0034] S2: Three-stage heating: Put the cut and polished glass into a tempering furnace for three-stage high-temperature tempering. The first stage is heated to 180°C and kept for 40 minutes, and the second stage is heated to 240°C. Keep it for 25 minutes, heat up to 300 degrees Celsius in the third stage, and keep it for 15 minutes;

[0035] S3: Three-stage cooling: Take out the glass after three-stage high-temperature tempering and put it into the cooling furnace for three-stage cooling. The first stage rapidly lowers the temperature to 260°C and keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com