Patents

Literature

40 results about "Ortho-hydroxybenzophenone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

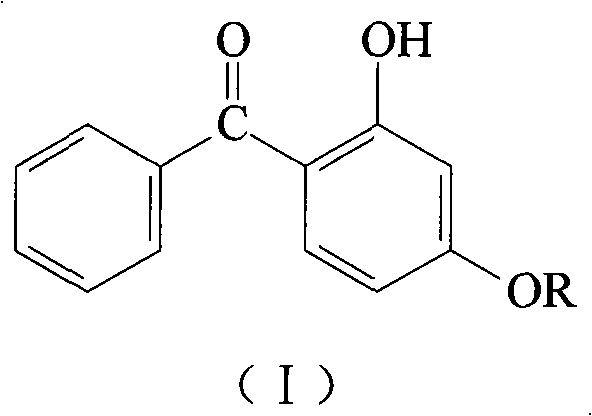

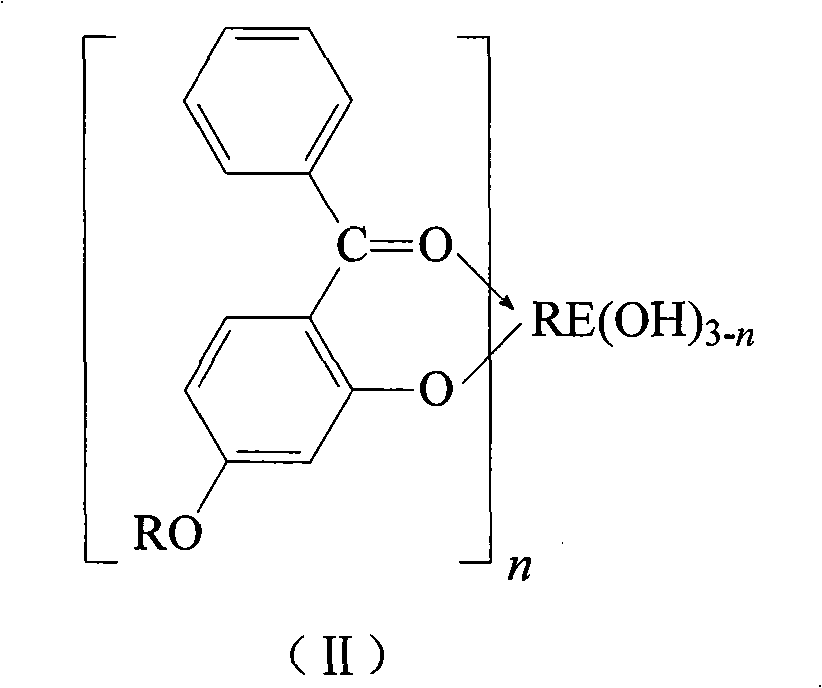

O-hydroxyl-diphenyl ketone- rare earth complex and its preparation method and uses

InactiveCN1730454ABlooming phenomenon is smallImprove photostabilityOrganic chemistryHeat resistanceRare earth

Disclosed is an o-hydroxyl-diphenyl ketone- rare earth complex and its preparation method and uses, which has a chemical formula of REL3-r(OH)x*mH2O, wherein RE is one from Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, Yb, or the combination of some of them by any proportion, or the mixed rare earth mainly containing these elements, L is ortho-hydroxyl diphenyl ketone anion, x=0-2, m=0-3. The invention also discloses the use of the complex as organic macromolecular material light-stability agent, which has the advantages of substancial optical stabilization property and improved heat-proof quality.

Owner:GUANGDONG UNIV OF TECH

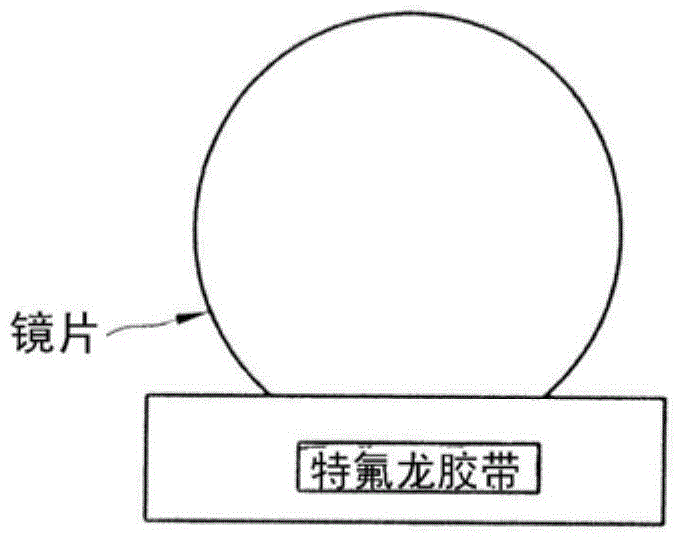

Fully polymerized UV blocking silicone hydrogel lens

A substantially fully copolymerized UV blocking hydrogel lens demonstrating sufficient blocking of UV light to meet at least FDA Class II specifications for UV blocking formed from a reaction mixture comprising at least NVP and one other comonomer and a free-radical polymerizable, substituted or unsubstituted, Bis Omicron-hydroxy benzophenone is provided herein.

Owner:BAUSCH & LOMB INC

Hydrotalcite composite environmental protection stabilizer for PVC, and preparation method thereof

InactiveCN105295242AImprove thermal stabilityPlay a role in thermal stabilityPhosphorous acidStearic acid

The present invention provides a hydrotalcite composite environmental protection stabilizer for PVC, wherein the hydrotalcite composite environmental protection stabilizer is prepared from the following raw materials by weight: 20-30 parts of modified magnesium aluminum hydrotalcite, 10-12 parts of octyl tin mercaptide, 6-9 parts of lanthanum laurate, 1-3 parts of triphenyl phosphite, 3-6 parts of zinc stearate, 2-4 parts of stearic acid, 2-4 parts of epoxidized soybean oil, 20-24 parts of diisononyl phthalate, 5-6 parts of carbitol, 2-3 parts of o-hydroxybenzophenone, and 10-15 parts of heavy calcium carbonate. According to the present invention, the PVC stabilizer has characteristics of good thermal stability, good processing performance, environmental protection, no toxicity, low cost, good plasticity and balance torque reducing during the PVC processing process, and low cost.

Owner:HWASU

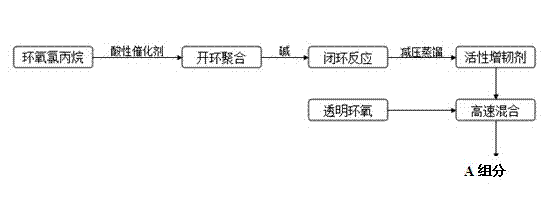

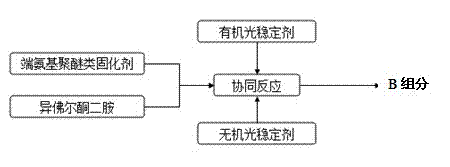

Preparation process of transparent epoxy nanocomposite material for encapsulating high-power LED (light-emitting diode)

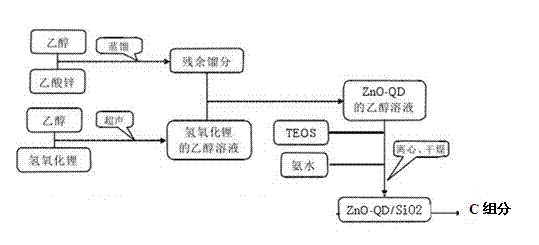

InactiveCN102675823AHigh content of primary aminesImprove toughnessSemiconductor devicesLithium hydroxideUltraviolet

The invention discloses a preparation process of a transparent epoxy nanocomposite material for encapsulating a high-power LED (light-emitting diode). The process comprises the following steps that epichlorohydrin is used as a raw material, an acid catalyst is added to carry out ring opening polymerization reaction, alkali is added to carry out closure reaction, and extraction and other processes are carried out to obtain a flexibilizer; amine terminated polyether curing agent and isophorone diamine are mixed, and ortho-hydroxy diphenyl ketone, benzotriazole ultraviolet vapor, hindered amine light stabilizer are added to carry out concerted reaction with nano SiO2 to obtain the required curing agent; ethanol and zinc acetate are mixed and distilled to obtain residual fractions; the residual fractions are mixed with an ethanol solution of lithium hydrate to obtain an ethanol solution of ZnO-QD, and tetraethoxysilane and ammonia water are added for centrifugation and drying to obtain ZnO-QD / SiO2; and the components are mixed and then mechanically dispersed, vacuumized, defoamed, poured and cured to obtain a ZnO-QD / SiO2 / epoxy encapsulating material.

Owner:唐来江

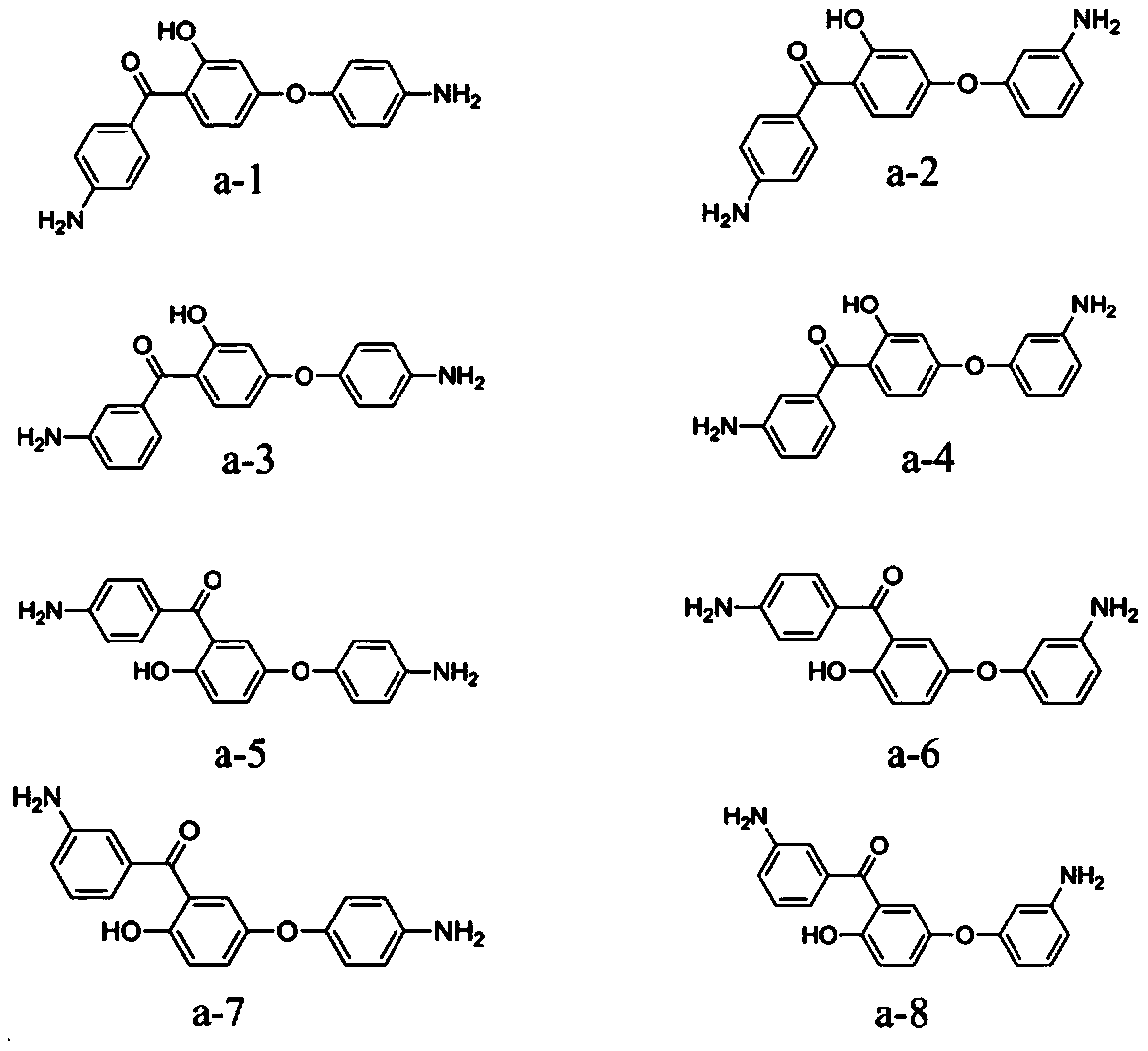

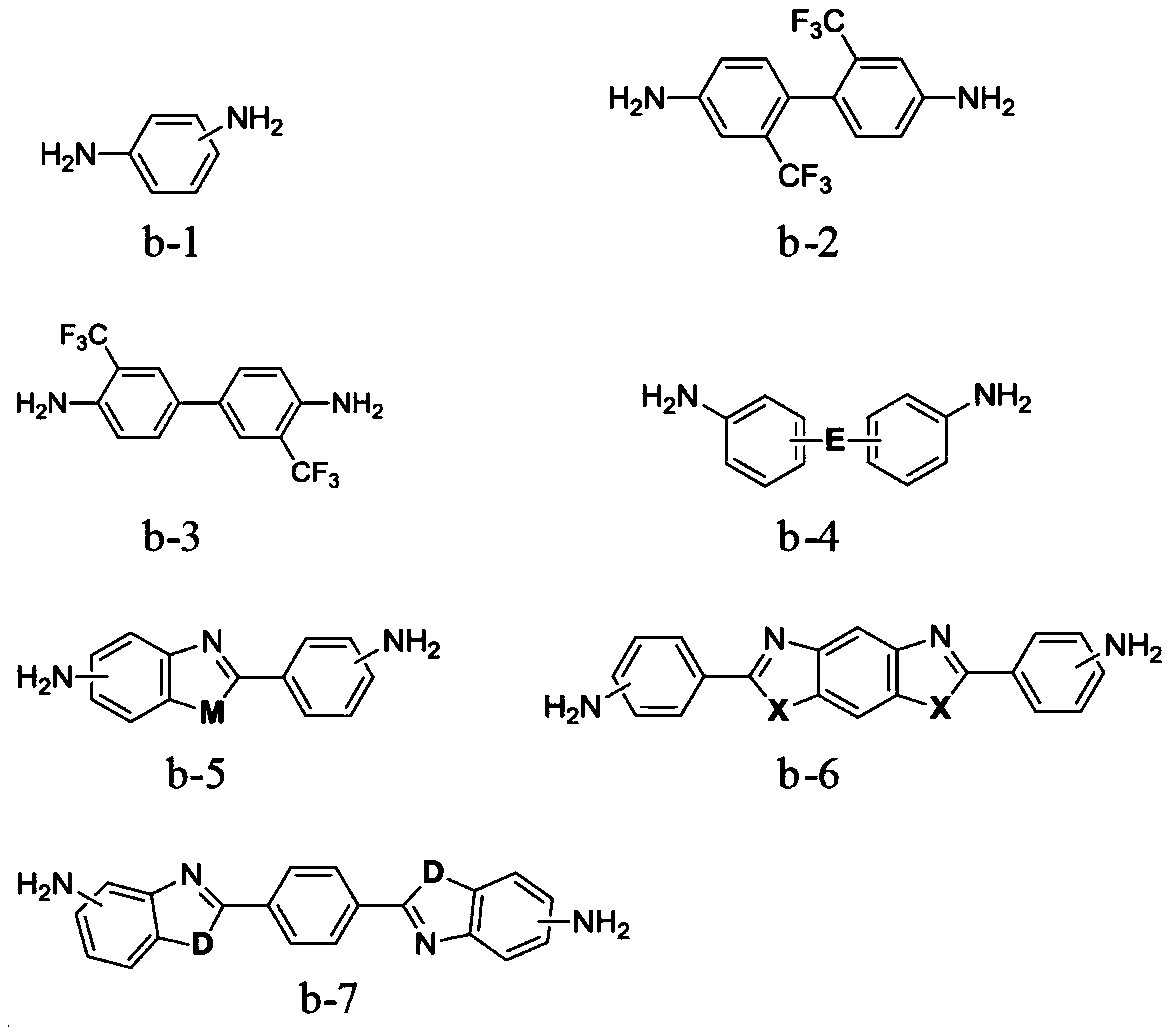

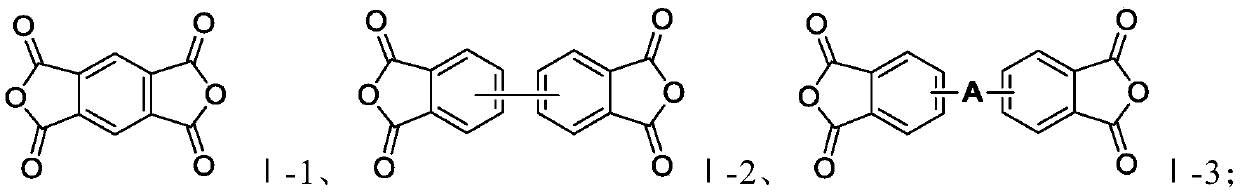

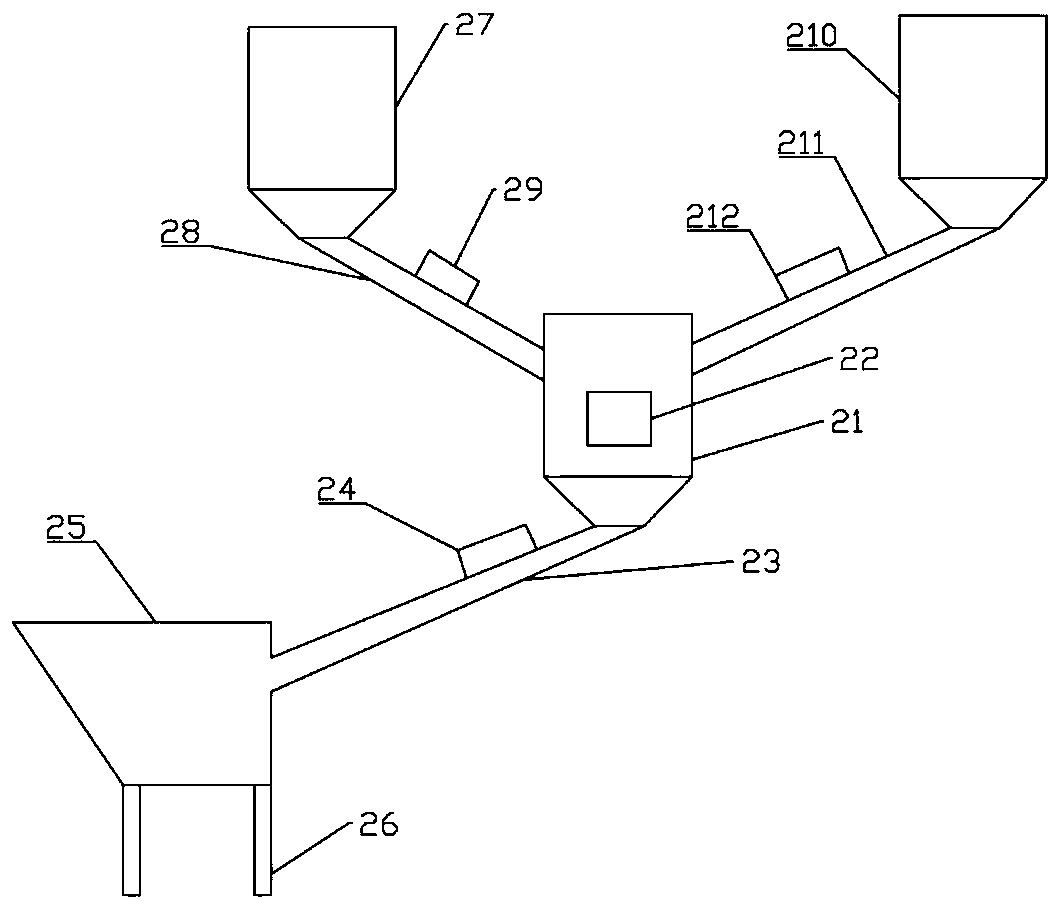

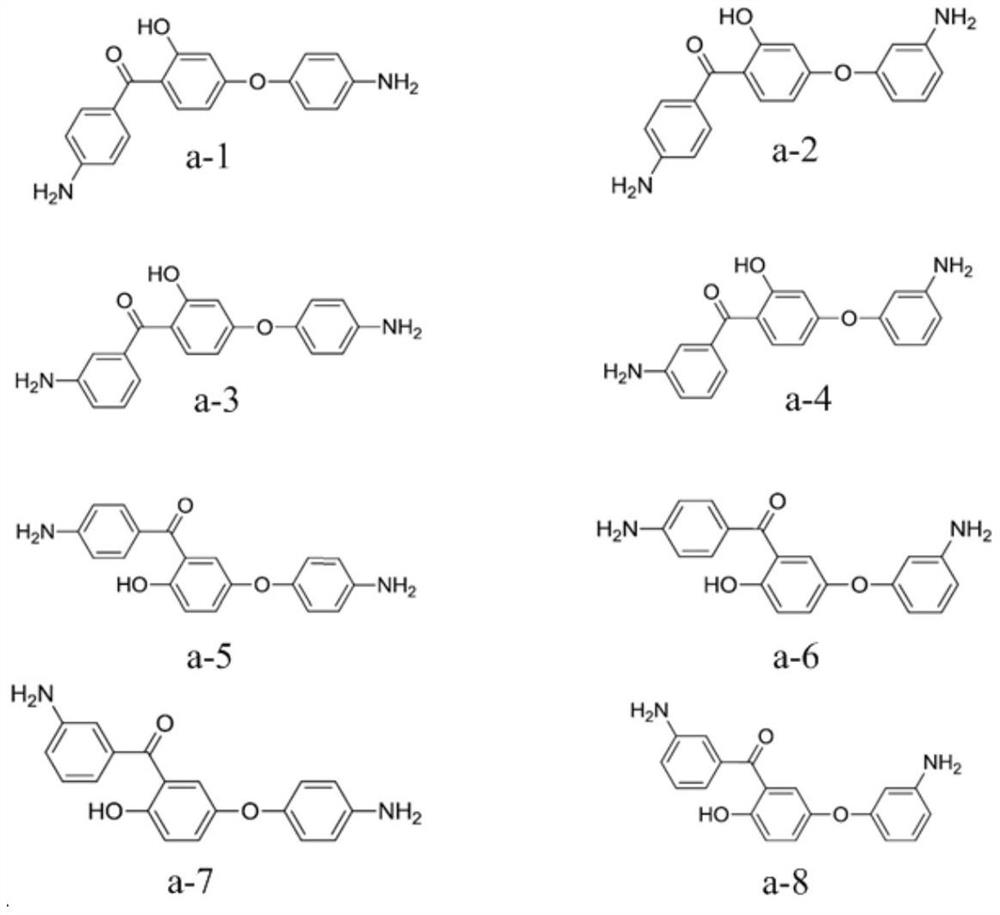

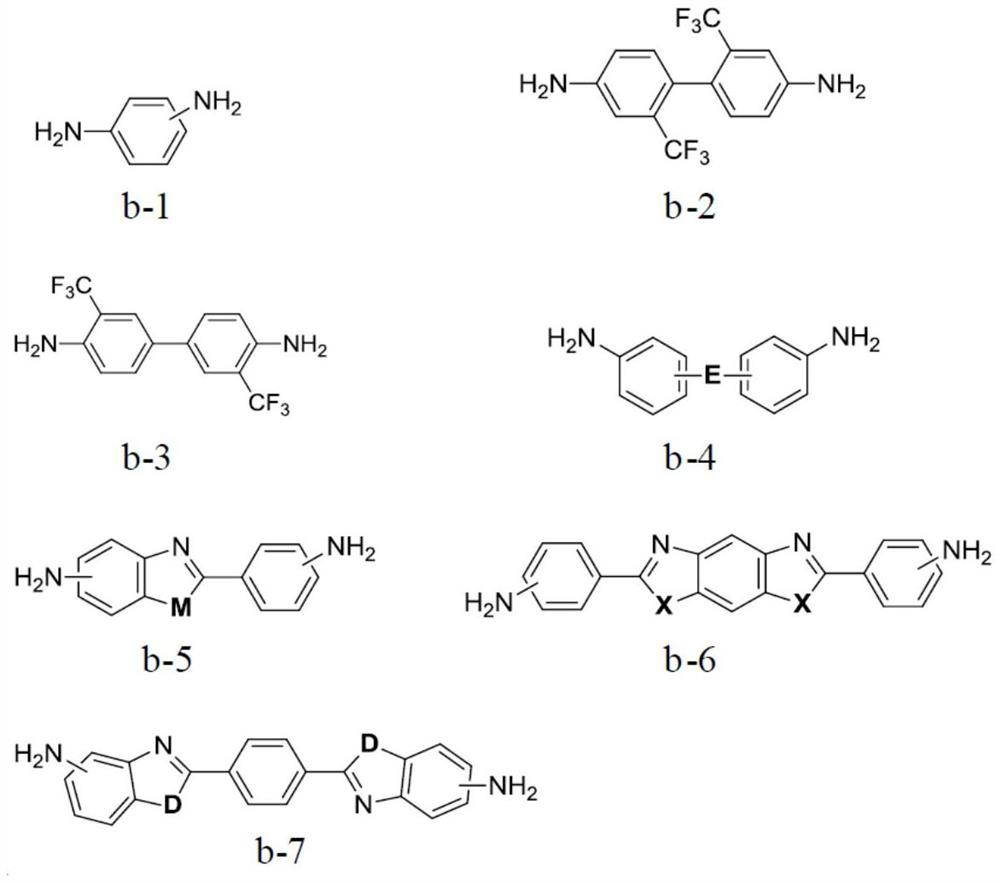

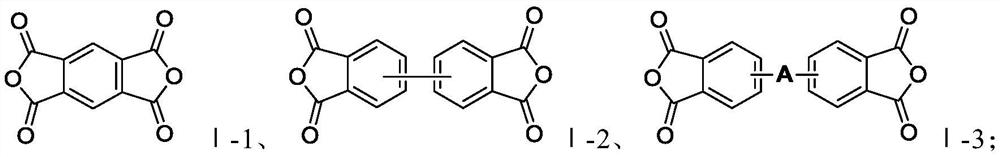

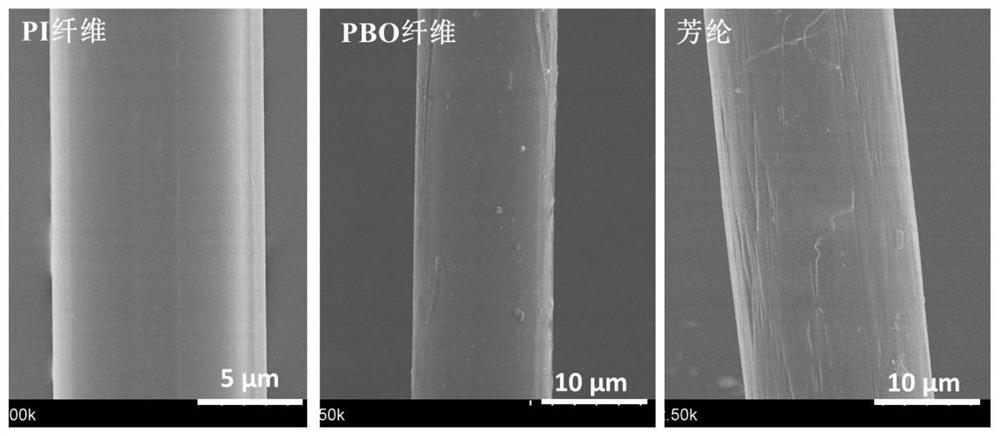

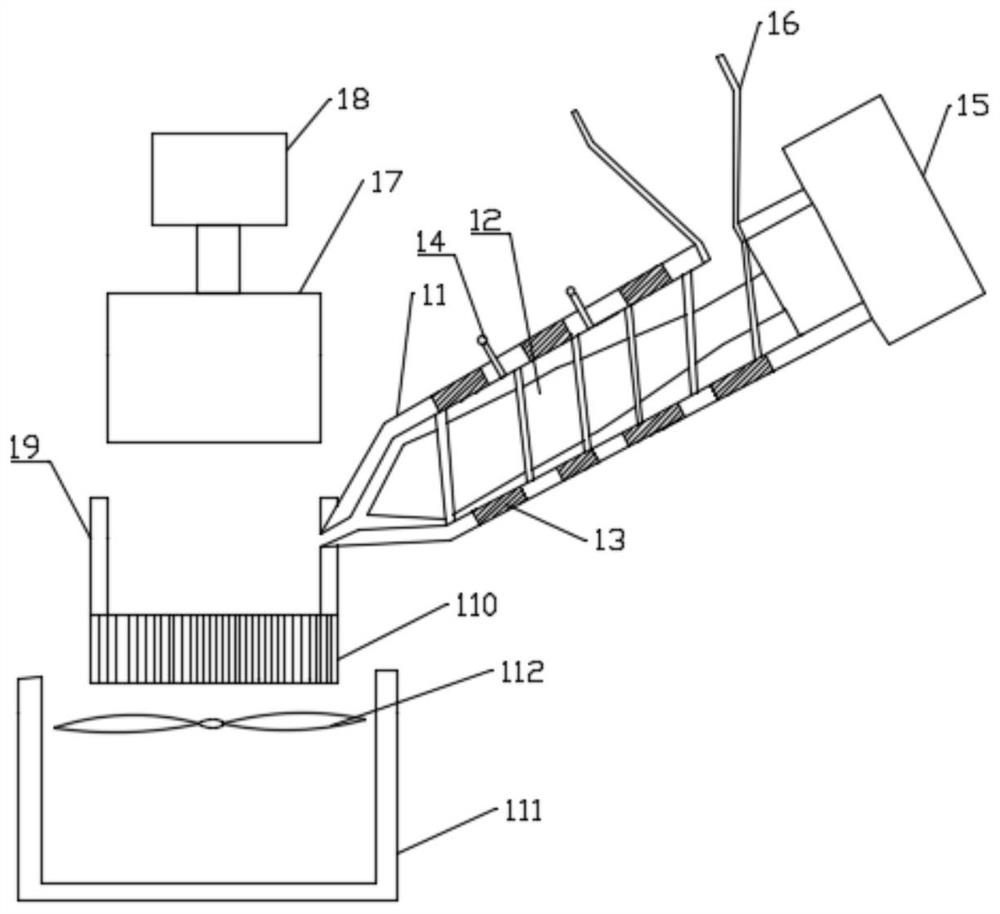

Polyimide fiber and preparation method thereof

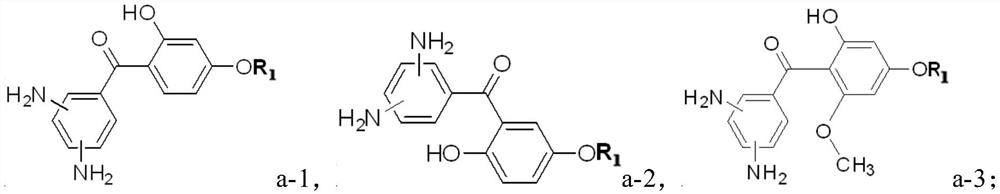

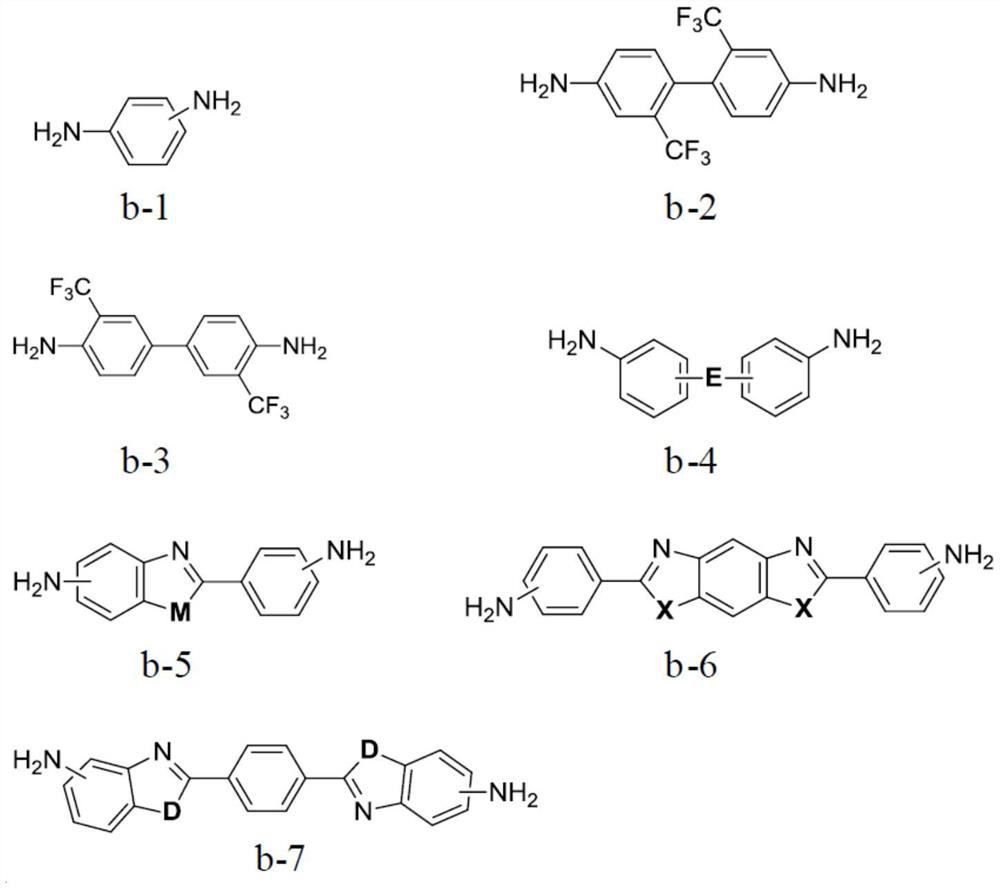

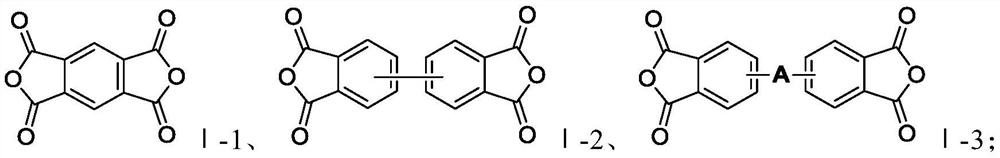

The invention provides a polyimide fiber and a preparation method thereof. The preparation method includes the steps: a) polymerizing an aromatic anhydride monomer and a diamine monomer to obtain polyamide acid spinning solution; b) spinning the polyamide acid spinning solution to obtain a polyamide acid fiber; c) performing imidization treatment on the polyamide acid fiber to obtain a polyimide fiber. The diamine monomer includes a monomer A and a monomer B, the monomer A is selected from one or more of structures from a formula a-1 to a formula a-8 as shown in the specification, and the monomer B is selected from one or more of structures from a formula b-1 to a formula b-7 as shown in the specification. According to the polyimide fiber, special monomer A and special monomer B are matched to serve as a diamine monomer, main chains of the monomer A and the monomer B contain o-hydroxybenzophenone structure units, the monomer A, the monomer B and aromatic anhydride monomer are polymerized and spun to obtain a polyimide fiber, special monomers are introduced, and the ultraviolet resistance and the ageing resistance of polyimide can be improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

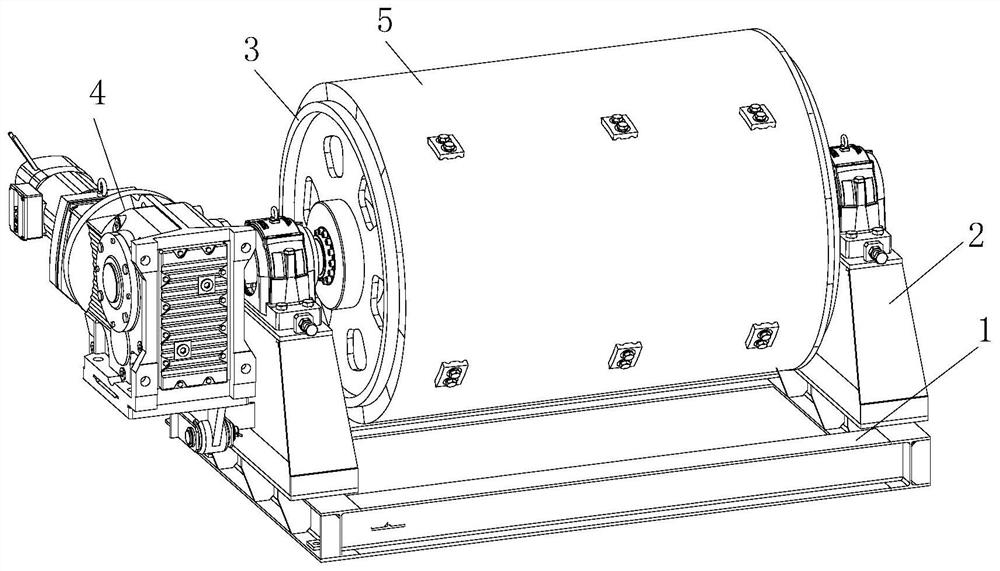

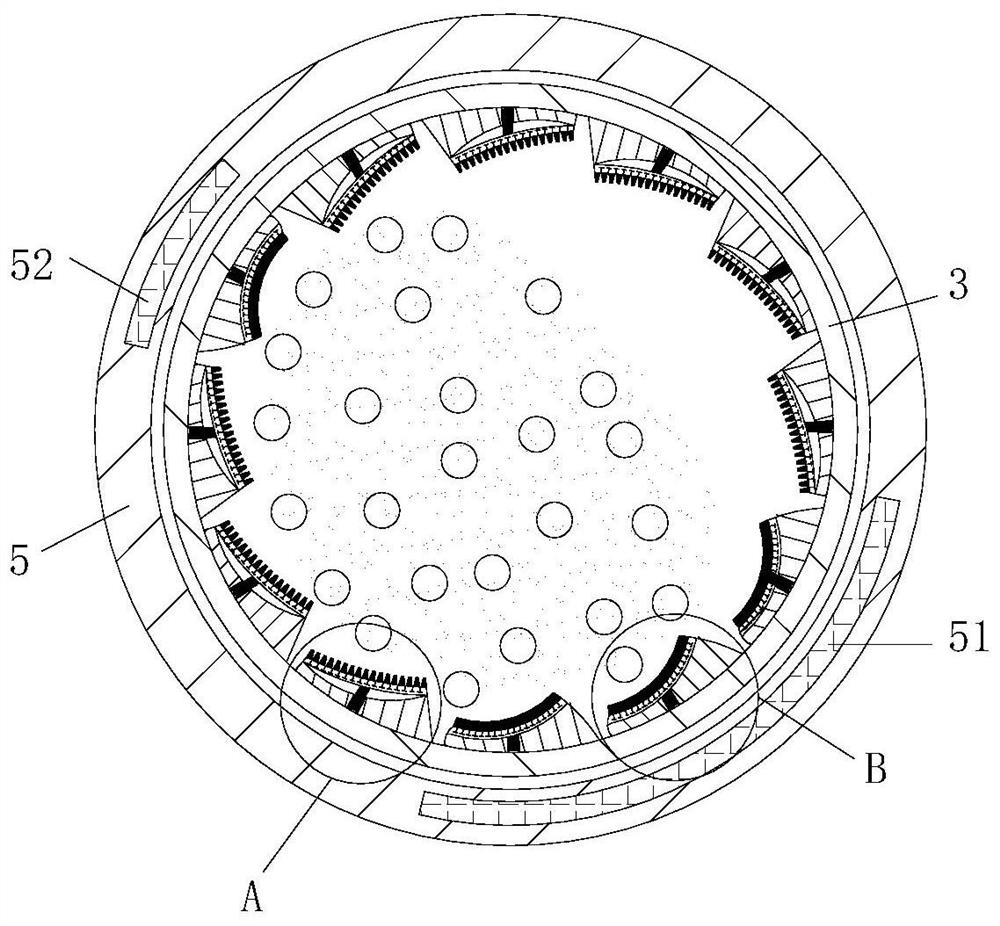

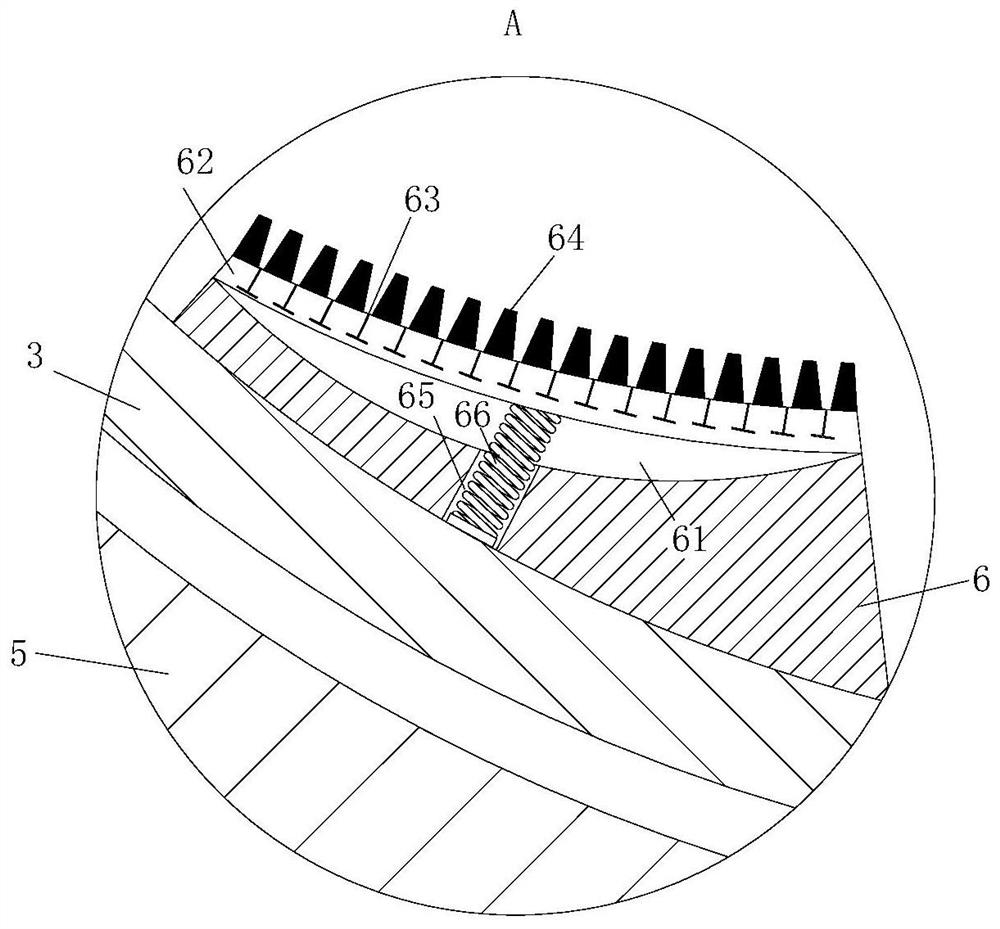

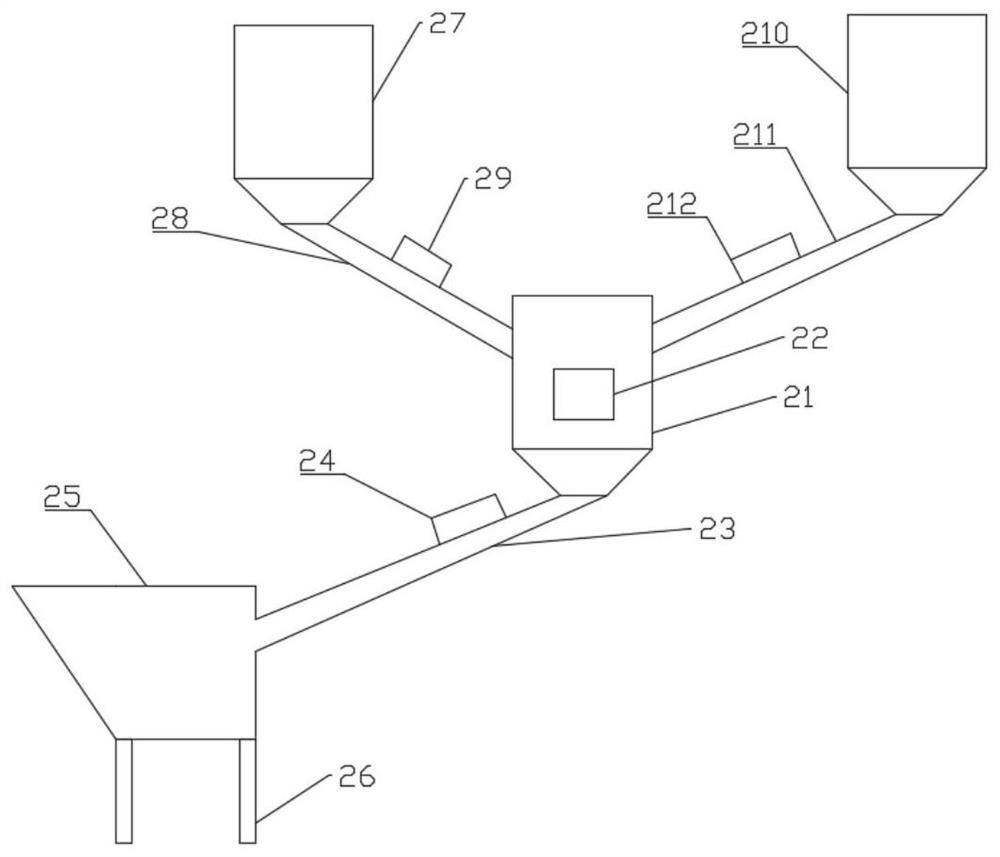

Novel masterbatch composite additive and production process thereof

InactiveCN111944202AGuaranteed qualityIncrease grind levelGrain treatmentsPhosphorous acidPolymer science

The invention relates to the technical field of masterbatch composite additives, in particular to a novel masterbatch composite additive and a production process thereof. The masterbatch composite additive is prepared from the following components in parts by weight: 20-25 parts of phosphite, 3-5 parts of alkyl imidazoline, 2-5 parts of o-hydroxybenzophenone, 2-5 parts of methylene dinaphthalene sodium sulfonate, 6-15 parts of calcium stearate, 18-25 parts of nano silicon dioxide and 1-3 parts of an ultraviolet light absorber. Through the arrangement of a lining plate, an arc-shaped surface, astainless steel elastic sheet, a rhagadia groove and a grinding sheet, the lifting height of a grinding medium and a material is greatly increased, the grinding level of the material is improved, andthe quality of a ground novel masterbatch composite additive is guaranteed; meanwhile, the motion state of the grinding medium is adjusted, and energy loss is reduced.

Owner:芜湖全木科技有限公司

Ultraviolet-resistant organic silicon adhesive and preparation method thereof

InactiveCN110527486AHigh refractive indexHigh light transmittanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesHydrogenAging resistance

The invention belongs to the technical field of macromolecule materials and provides an ultraviolet-resistant organic silicon adhesive and a preparation method thereof. The ultraviolet-resistant organic silicon adhesive comprises a component A and a component B, wherein the component A comprises the following components in parts by weight: 20-50 parts of an epoxy group containing alkene type unsaturated compound, 10-18 parts of vinyl terminated polysiloxane of 400-2000cps, 0.5-1 part of polyvinyl polysiloxane and 0.009-0.1 part of a platinum catalyst; the component B comprises the following components in parts by weight: 25-40 parts of f vinyl terminated polysiloxane of 400-2000cps, 10-16 parts of terminated hydrogen-containing polysiloxane, 5-10 parts of o-hydroxydibenzophenone and 0.5-5parts of a polyallyl compound; and the weight percentage of platinum in the platinum catalyst is 0.1-0.15%. The component A is prepared in an opening system, the component B is prepared in a sealed system, and the two components are mixed to prepare the adhesive. By adopting the preparation method of the ultraviolet-resistant organic silicon adhesive, production conditions can be simplified, the production time can be shortened, and the prepared ultraviolet-resistant organic silicon adhesive has a very high refractive index, light transmittance and ultraviolet aging resistance.

Owner:丁爱顺

High-flame-retardant, high-strength and high-temperature-resistant easy-to-form thermoplastic plate and preparation method thereof

InactiveCN110396272AImproves UV resistanceImprove anti-aging propertiesProcedure AgentsPolyvinyl chloride

The invention discloses a high-flame-retardant, high-strength and high-temperature-resistant easy-to-form thermoplastic plate and a preparation method thereof, and belongs to the field of easily-formed thermoplastic plates. The thermoplastic plate is prepared from the following raw materials by weight: 10-30 parts of MBS, 10-30 parts of polyvinyl chloride resin, 30-45 parts of ABS, 8-15 parts of PMMA, 1-2 parts of a heat stabilizer, 0.5-2 parts of an auxiliary stabilizer, 1-2 parts of an o-hydroxybenzophenone derivative, 1-4 parts of an outer lubricant, 1-4 parts of an inner lubricant, 1-2 parts of a processing aid, 2-5 parts of an impact modifier and 0-1 part of a pigment. When the temperature increases to 80 DEG C, the processing aid, the pigment and the impact modifier are added in parts by weight; when the temperature increases to 125 DEG C, the mixture is fed into a cold mixing device to be cooled and stirred, the stirring speed being 80 rpm; and the product is obtained when the temperature decreases to 40 DEG C. The product is reasonable in components and simple to prepare, has remarkable advantages and is suitable for popularization and application.

Owner:浙江数合新材料有限公司

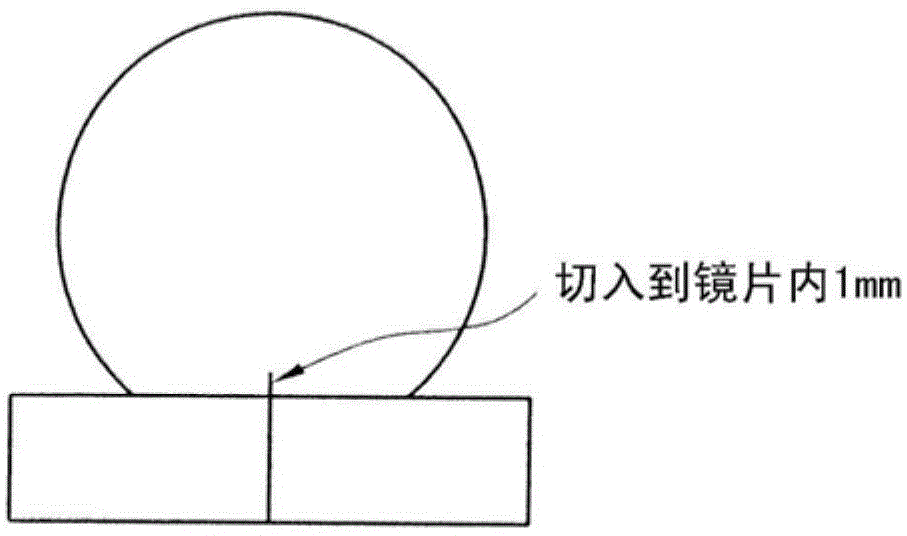

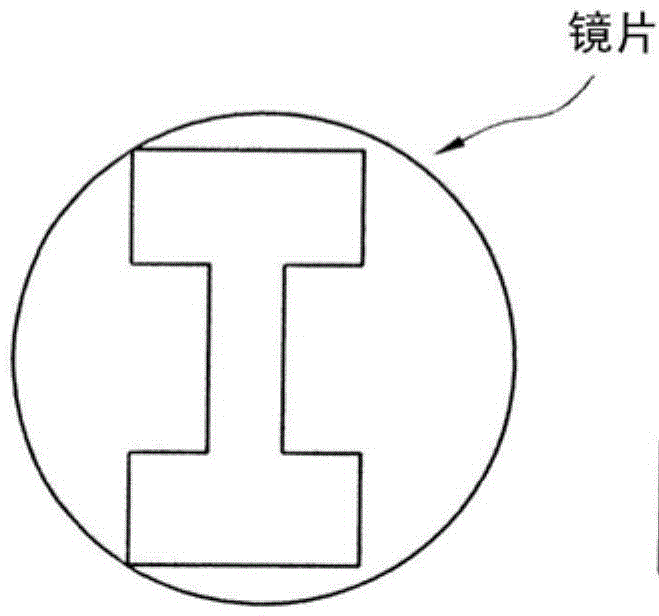

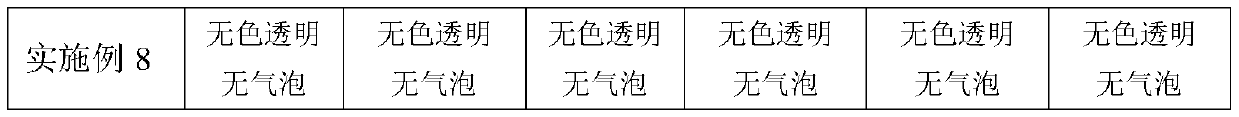

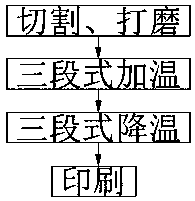

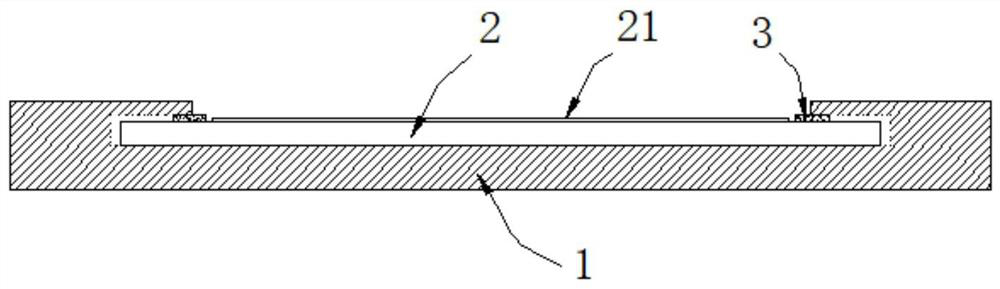

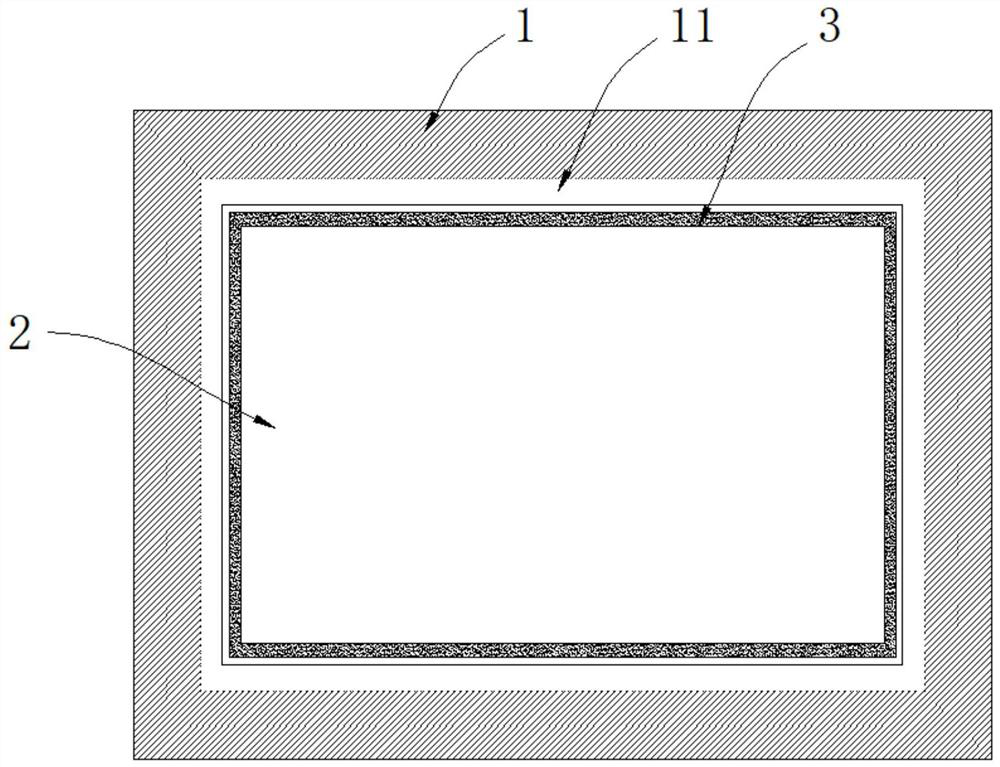

Method for preparing panel glass of washing machine

InactiveCN110104942AGuaranteed sizeImprove temperature resistanceOther washing machinesInks2-hydroxybenzophenoneAlkalinity

The invention discloses a method for preparing panel glass of a washing machine in the technical field of household appliances. The method comprises the steps of cutting and polishing, wherein glass is cut into a required size, and the periphery of the glass is polished by a laser polishing machine to be smooth; three-stage heating, wherein the cut and polished glass is put into a tempering furnace for three-stage high-temperature tempering. According to the method, the size of the glass can be effectively guaranteed through laser polishing, the polished corners are smooth, and the subsequentprocess can be effectively guaranteed; through three-stage heating and cooling, the temperature resistance of the glass is effectively improved, and the impact resistance of the glass is improved; byadding polyethylene resin, N-diphenyl-p-phenylenediamine and 2-hydroxybenzophenone to ink, the low temperature resistance, water resistance and acid resistance, acidity and alkalinity, oxidation resistance and light resistance of the ink are effectively improved, and the service life of the ink is prolonged.

Owner:安徽凤阳赛弗节能玻璃有限公司

Heat-resistant and sun-proof fiber asphalt paint and preparation method thereof

InactiveCN104293184AHigh viscosityFlame retardantFireproof paintsBituminous coatingsPolyethylene terephthalate glycolMeth-

The invention discloses heat-resistant and sun-proof fiber asphalt paint. The heat-resistant and sun-proof fiber asphalt paint is characterized by being prepared from the following raw materials in parts by weight: 12-17 parts of methyl silicone resin, 3-5 parts of liquid polysulfide rubber, 4-7 parts of methylene biscyclohexane amine, 0.1-0.4 part of o-hydroxybenzophenone, 2-4 parts of carbon black, 3-4 parts of nano aluminum nitride, 2-4 parts of mica powder, 2-3 parts of vermiculite powder, 2-3 parts of a polyethylene terephthalate fiber, 1-2 parts of a bamboo fiber, 2-3 parts of a polyvinyl alcohol fiber, 0.6-1.0 part of cuprous thiocyanate, 35-43 parts of modified asphalt, 6-10 parts of modified waste sodium silicate sand, 1-2 parts of a silane coupling agent KH560, 0.3-0.8 part of fluorescent powder, 6-9 parts of dimethylbenzene, 6-8 parts of sodium lignosulphonate, 5-7 parts of n-butyl acetate and 4-6 parts of trichloroacetic acid. According to the paint disclosed by the invention, the added mica powder is good in abrasion resistance and wear resistance, is heat-resistant and insulating, is hard to dissolve in acidic and alkaline solutions, and is stable in chemical performance; the added vermiculite powder can be used for increasing the viscosity of the paint, and has a flame-retardant effect; added o-hydroxybenzophenone and carbon black can be used for increasing the photo-stability of the paint, and are hard to age; and added nano aluminum nitride has good heat conduction and insulation properties. The heat-resistant and sun-proof fiber asphalt paint also can be used for modifying the waste sodium silicate sand, can be used for increasing the water resistance, fire resistance and dispersion performance of the paint, solves the problem of soil pollution, and also can be used for protecting the environment.

Owner:TIANCHANG YINHU PAINT

Anti-ultraviolet fading-resistant nylon composite material and preparation method thereof

The invention discloses an anti-ultraviolet fading-resistant nylon composite material which is characterized by being prepared from the following raw materials in parts by weight: 8-11 parts of sericite, 0.5-1 part of phenyl salicylate, 0.5-1 part of isocetyl myristate, 0.2-0.4 part of an antioxidant DLTP, 1-2 parts of polyacrylamide, 2-3 parts of 4-hydroxybenzophenone, 90-100 parts of nylon 6, 2.5-3.2 parts of lithium chloride, 3-9 parts of epoxy resin E51, 10-15 parts of EVA emulsion, 60-80 parts of ethyl acetate, 1-3 parts of castor oil, 4-7 parts of ethylene / vinyl alcohol copolymer powder and 15-30 parts of distilled water. According to the invention, since the surface of a reinforcing body is wrapped and activated by the ethylene / vinyl alcohol copolymer, compatibility between the reinforcing body and the nylon 6 is improved, the reduction of the mechanical property of the nylon 6 is avoided, the added sericite has the effects of reducing resistance and lubricating, the mechanical strength of the material is enhanced, and the added 4-hydroxybenzophenone has the property of improving the ultraviolet resistance of the product and has the effects of fading resistance.

Owner:HEFEI KANGLING HEALTH TECH

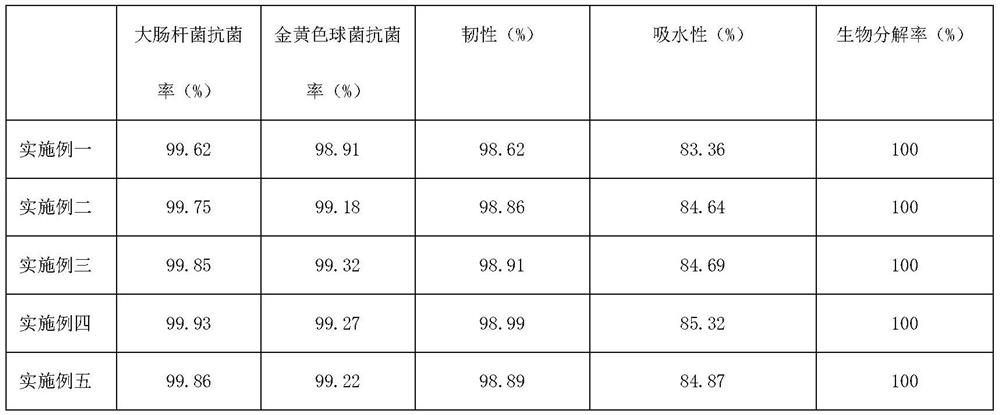

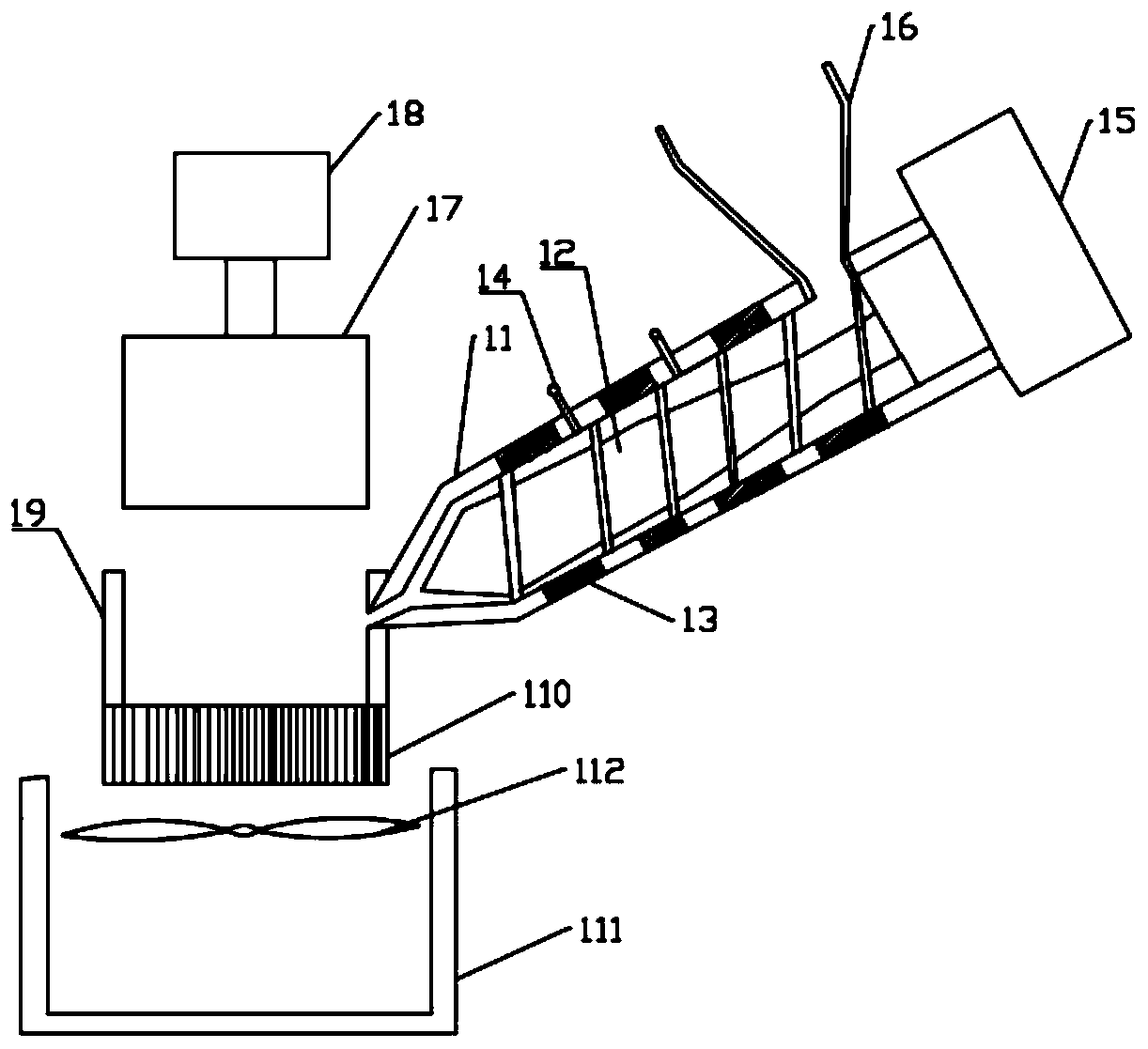

Preparation method of napkin paper product with high-precision artistic patterns

InactiveCN112941966AStable structureGood antibacterial effectNon-macromolecular organic additionVegetable material additionAntibacterial agentPolyacrylamide

The invention discloses a preparation method of a napkin paper product with high-precision artistic patterns. The napkin paper product comprises a napkin paper carrier, a water-soluble film and a sealing layer, the water-soluble film is attached to the single face or the double faces of the napkin paper carrier through the sealing layer, and patterns are printed on the outer end face and / or the inner end face of the water-soluble film; the edge of the paper napkin carrier wraps the periphery of the water-soluble film; and the paper napkin carrier is prepared from the following components in parts by weight: 60 to 85 parts of paper pulp, 45 to 62 parts of polylactic acid, 20 to 25 parts of modified nano montmorillonite, 18 to 23 parts of PEG-40 hydrogenated castor oil, 18 to 21 parts of a hydrophilic polymer, 15 to 20 parts of anionic polyacrylamide, 15 to 20 parts of perlite powder, 16 to 19 parts of sweet-scented osmanthus extract, 12 to 17 parts of a folium artemisiae argyi extracting solution, 10 to 15 parts of o-hydroxybenzophenone derivative, 9-14 parts of graphene oxide and 3-8 parts of an antibacterial agent. The napkin paper product is simple in preparation process, high in antibacterial performance, high in degradation rate, low in cost, safe, environmentally friendly and suitable for the field of packaging of napkin paper products and other paper products.

Owner:福建东南艺术纸品股份有限公司

Preparation method of woven bag with strong anti-aging effect

ActiveCN110983473AImprove anti-aging propertiesBag making operationsPaper-makingEmulsionPlastic film

The invention relates to a preparation method of a woven bag, in particular to a preparation method of the woven bag with a strong anti-aging effect. The method comprises the following steps of mixingmountain flour, recycled plastic, color master batch, first wood powder, first tourmaline powder and o-hydroxybenzophenone, melting and mixing with a beta nucleating agent at the high temperature of250 DEG C to obtain a molten material, extruding into a plastic film through a die head, and cooling and shaping the water tank; stretching the film; preparing coating liquid, stirring porous powder quartz powder, second tourmaline powder, second wood powder, acrylic emulsion and water to obtain the coating liquid; uniformly applying the coating liquid to the surface of the obtained film, heatingthe coated film at 150 DEG C for 1-3 minutes and drying; and making the coated film form a silk ingot through a drawbench unit, weaving to tubular fabric of the woven bag, and carrying out machine sewing to obtain the woven bag. According to the method, the anti-aging effect of the woven bag prepared by the recycled plastic is improved through the mountain flour, the wood powder and the tourmalinepowder.

Owner:福清市洪裕塑胶有限公司

A kind of polyimide fiber and preparation method thereof

The invention provides a polyimide fiber and a preparation method thereof. The polyimide fiber provided by the present invention and the preparation method thereof comprise the following steps: a) polymerizing the aromatic dianhydride monomer and the diamine monomer in a solvent to obtain a polyamic acid spinning stock solution; b) making the polyamide Spinning the acid spinning stock solution to obtain polyamic acid fibers; c) imidizing the polyamic acid fibers to obtain polyimide fibers; the diamine monomers include monomer A and monomer B; the monomer A is selected from one or more of the structures of formula a-1 to formula a-8 shown below; the monomer B is selected from the structures of formula b-1 to formula b-7 shown below one or more of them. In the present invention, the specific monomer A containing o-hydroxybenzophenone structural units in the main chain is matched with the monomer B as a diamine monomer, polymerized and spun with a dianhydride monomer to obtain polyimide fibers, and the specific monomer The introduction of can improve the UV aging resistance of polyimide.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

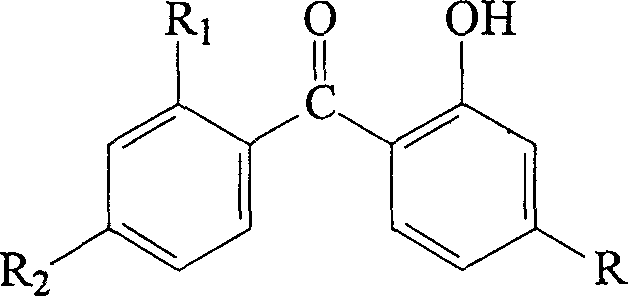

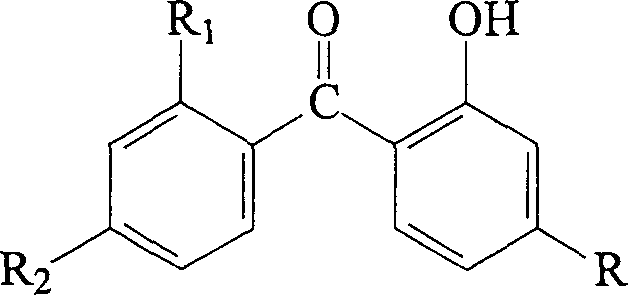

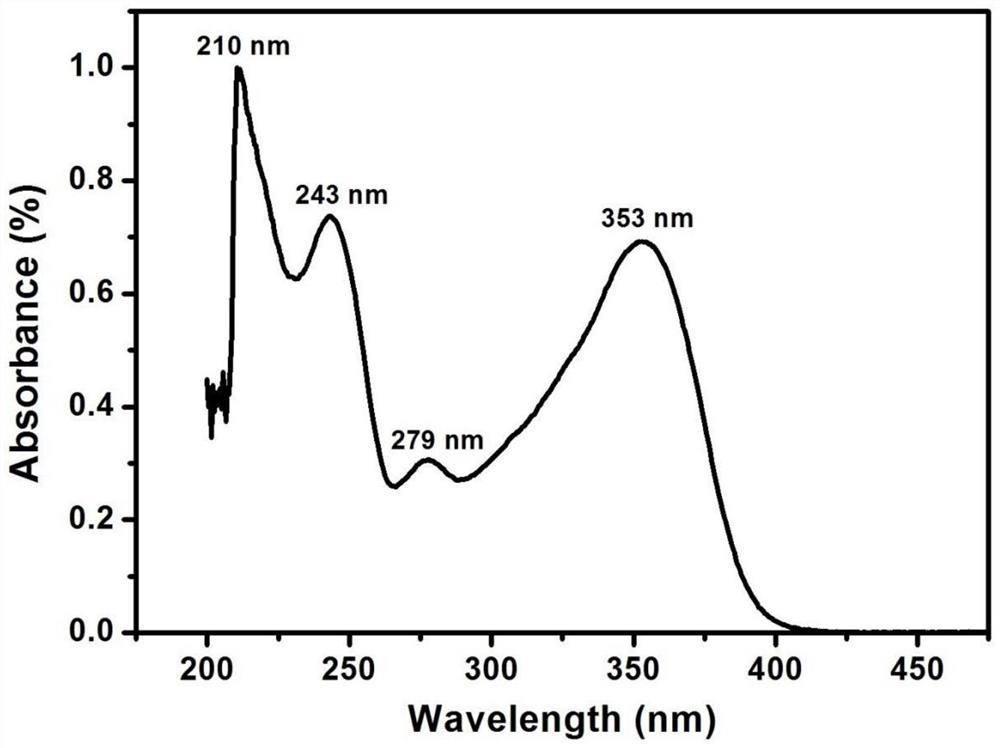

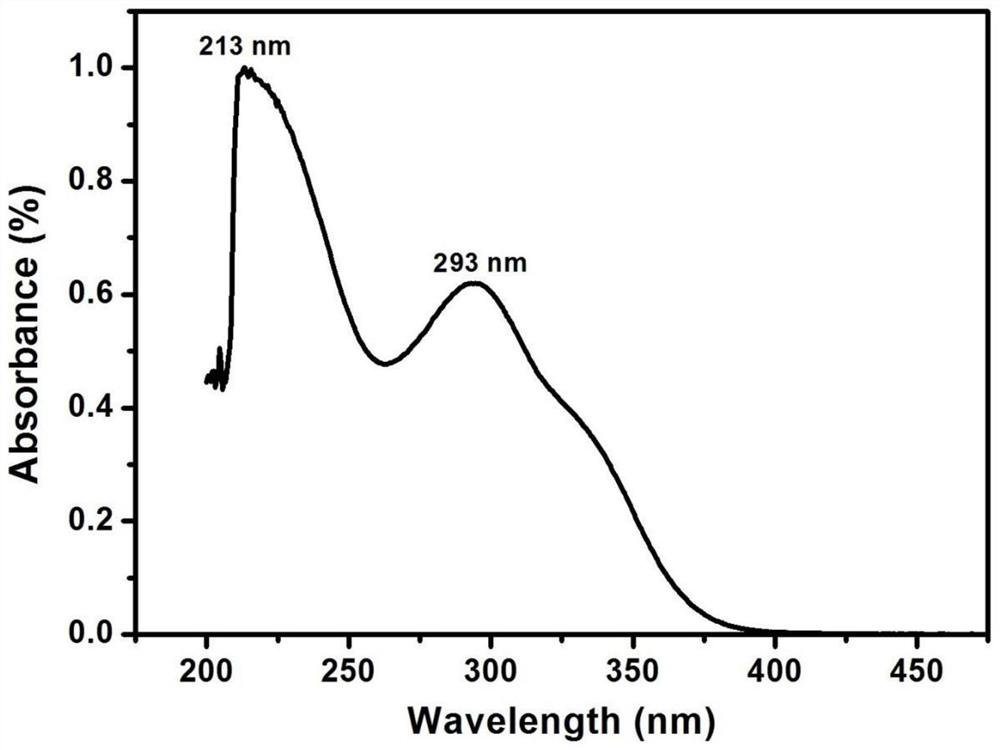

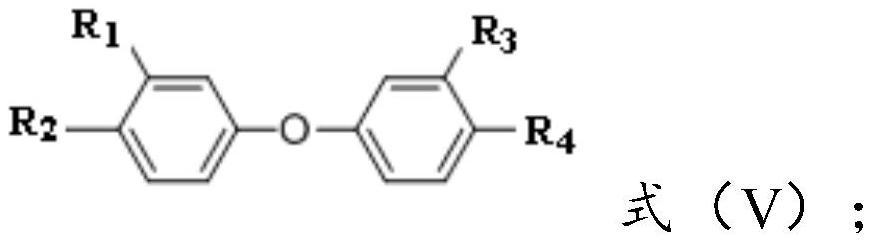

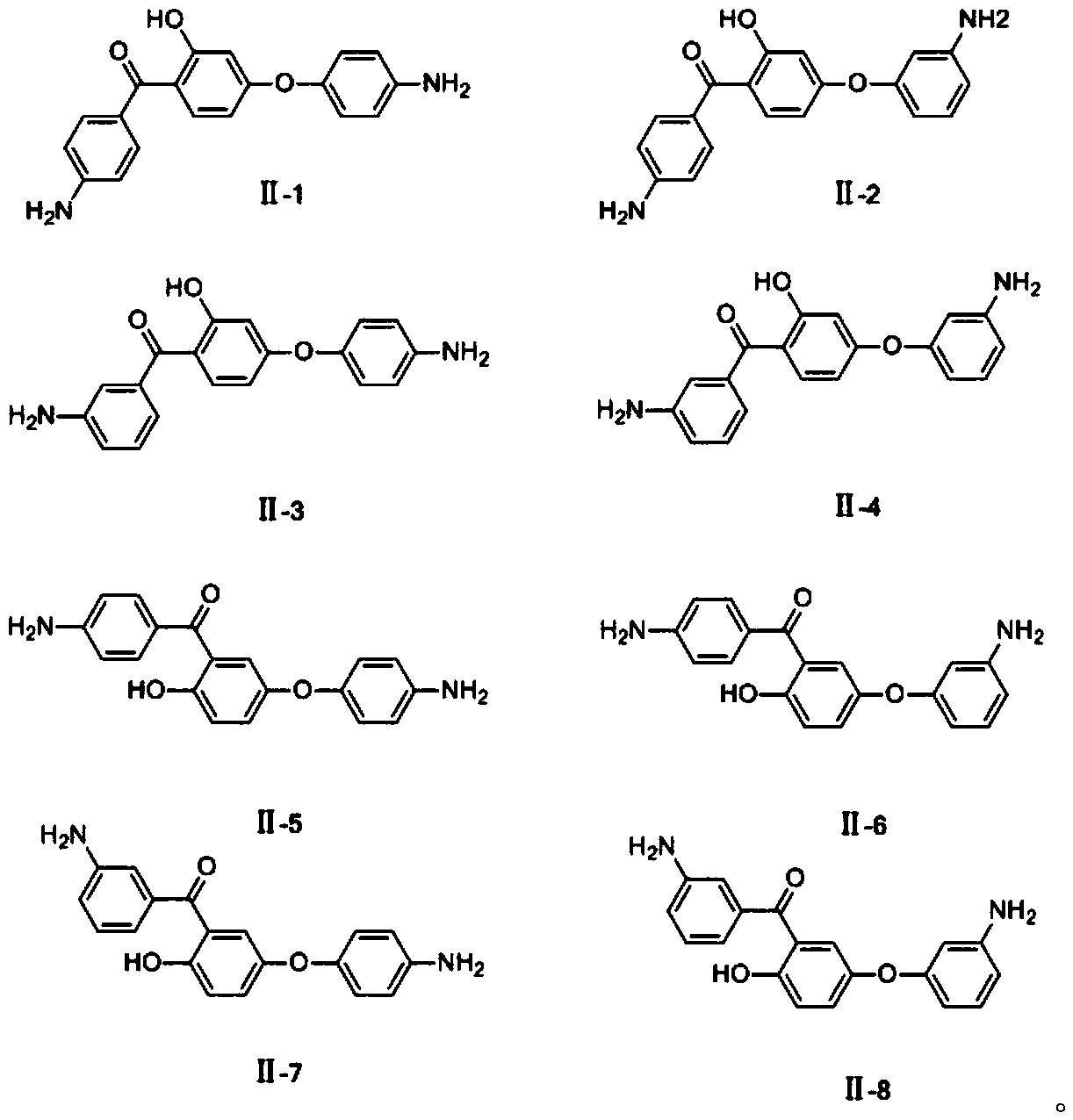

A kind of aromatic diamine monomer and preparation method thereof

ActiveCN110669337BPrevent or delay damageExcellent intrinsic UV resistancePolymer scienceUltraviolet lights

The present invention provides an aromatic diamine monomer having a structure shown in formula (V); in formula (V), R 1 and R 2 independently selected from hydroxyl or and R 1 with R 2 different, R 3 , R 4 , R 5 , R 6 are independently selected from hydrogen or amino, and R 3 with R 4 different, R 5 with R 6 different. Compared with the prior art, the aromatic diamine monomer provided by the present invention contains o-hydroxybenzophenone structural units, and the o-hydroxybenzophenone structural units can be introduced into the main body of polyimide polymer materials through copolymerization. chain, when the material is exposed to ultraviolet radiation, the o-hydroxybenzophenone structure can absorb ultraviolet light and release it in the form of heat, preventing or delaying the damage of polyimide material by ultraviolet radiation, so that the obtained polyimide The imine material has excellent intrinsic anti-ultraviolet radiation performance;

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Seawater corrosion resistant thermoplastic polyurethane elastomer rubber and preparation method thereof

InactiveCN110564130AReasonable formulaImprove seawater corrosion resistanceBulk chemical productionRubber materialPhthalate

The invention relates to the technical field of foamed plastics, and specifically discloses seawater corrosion resistant thermoplastic polyurethane elastomer rubber. The seawater corrosion resistant thermoplastic polyurethane elastomer rubber is prepared from the following components: TPU (thermoplastic polyurethane elastomer), EPDM (Ethylene-Propylene-Diene Monomer) thermoplastic elastomer, hydrogenated carboxylated butyronitrile, dioctyl phthalate, dibutyl phthalate, dioctyl adipate, ortho-hydroxy benzophenone, ultraviolet absorbent, reinforcement filling agents, silane coupling agents and calcium sulfide. The invention further discloses a preparation method of the seawater corrosion resistant thermoplastic polyurethane elastomer rubber. The preparation method comprises the following manufacturing steps of (S1) matching and weighing; (S2) mixing rubber materials; (S3) adding accessory ingredients; (S4) modifying the coupling agents; (S5) extruding at a first stage; and (S6) extrudingat a second stage. The seawater corrosion resistant thermoplastic polyurethane elastomer rubber has the beneficial effects that the formula is reasonable, the seawater corrosion resistant performanceis improved by mixing the EPDM thermoplastic elastomer, the self tensile strength and compressive strength are increased through supercritical extrusion, and the service life is long.

Owner:HUBEI UNIV OF ARTS & SCI

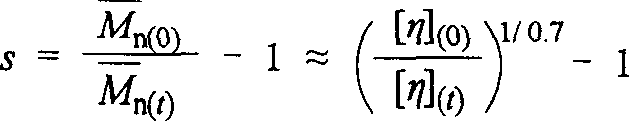

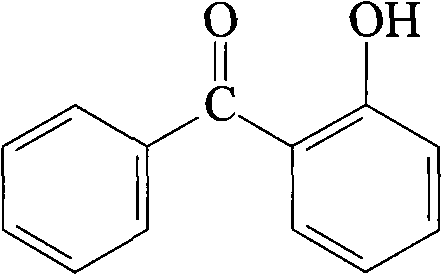

Method for synthesizing o-hydroxy benzophenone-rare earth coordination compound

InactiveCN101659605AEasy to operateReduce solubilityPreparation of aldehyde/ketone chelatesWater useOrganic solvent

The invention discloses a method for synthesizing an o-hydroxy benzophenone-rare earth coordination compound. The synthesis method comprises the following steps: firstly, mixing o-hydroxy benzophenone, water soluble rare earth salt, alkali and water used as a reaction medium according to the stoichiometric ratio at a temperature below the melting point of the o-hydroxy benzophenone, then stirring, regulating the temperature, reacting, completing the reaction and obtaining a product of the o-hydroxy benzophenone-rare earth coordination compound by filtering, washing, dewatering and drying the obtained product. The invention realizes that the water is used as the reaction medium for synthesizing the o-hydroxy benzophenone-rare earth coordination compound by a one-step reaction; compared with the prior art requiring taking an organic solvent as the reaction medium, the operation is greatly simplified, the yield, the production efficiency, the environmental protection and the safety are obviously enhanced, and the production cost is correspondingly lowered.

Owner:GUANGDONG UNIV OF TECH

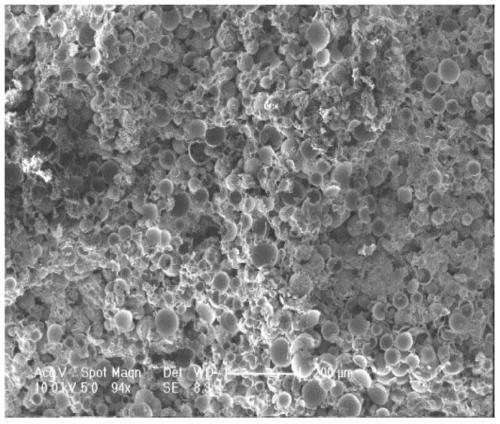

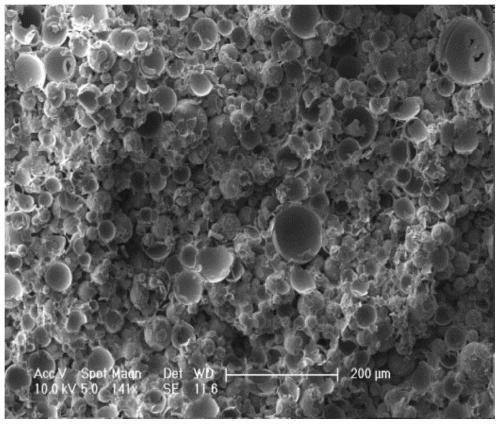

Polyimide composite foam precursor powder and polyimide composite foam

InactiveCN110256673AExcellent resistance to radiationImprove mechanical propertiesMicrosphereStructural unit

The invention provides a polyimide composite foam precursor powder and a polyimide composite foam. The polyimide composite foam is prepared by the method of: polymerizing aromatic dianhydride, aromatic diamine and an end-capping agent in an organic solvent; mixing the obtained polyamide acid solution with non-polar aromatic hydrocarbon and hollow microspheres, conducting cyclodehydration, precipitating powder, and then performing washing and drying to obtain polyimide composite foam precursor powder; and then carrying out compression molding to obtain the polyimide composite foam. According to the invention, aromatic diamine with a structure of II-1 to II-8 and other polymerization monomers are employed to prepare polyimide matrix resin, an o-hydroxydiphenyl ketone structural unit is introduced into a polyimide molecular chain to form a hydrogen bond in the molecular chain of polyimide, thus enhancing the interfacial bonding ability with the hollow microspheres, and effectively improving the mechanical properties of the composite foam; and the structure endows the composite foam with excellent ray radiation resistance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

BOPET anti-UV master batch material and preparation process thereof

The invention discloses a BOPET anti-UV master batch material and a preparation process thereof, and relates to the technical field of high polymer materials. The light-cured insect-resistant plasticcomprises the following components in parts by weight: 5-7 parts of a light stabilizer, 3-5 parts of an antioxidant, 3-5 parts of an insect-resistant agent, 5-7 parts of a coloring agent, 5-7 parts ofa compatilizer, 3-5 parts of a nucleating agent, 5-7 parts of a dispersion lubricant, 10-13 parts of a filling agent and 20-30 parts of carrier resin. The light stabilizer is a mixture of a light shielding agent, an ultraviolet light absorber and a quenching agent, wherein the light shielding agent is carbon black, the ultraviolet light absorber is a mixture of o-hydroxydiphenyl ketone, benzotriazole and salicylate, and the quenching agent is a divalent organic nickel chelate. The light stabilizer is a mixture of a light shielding agent, an ultraviolet light absorber and a quenching agent, the light shielding agent is carbon black, the ultraviolet light absorber is a mixture of o-hydroxybenzophenone, benzotriazole and salicylate, and the quenching agent is a divalent organic nickel chelate. The BOPET master batch is uniform in color and luster and can delay aging caused by solar radiation under direct sunlight radiation.

Owner:SHENZHEN JINZHICHENG PLASTIC TECH CO LTD

Preparation method of high-strength weather-resistant polyimide fiber

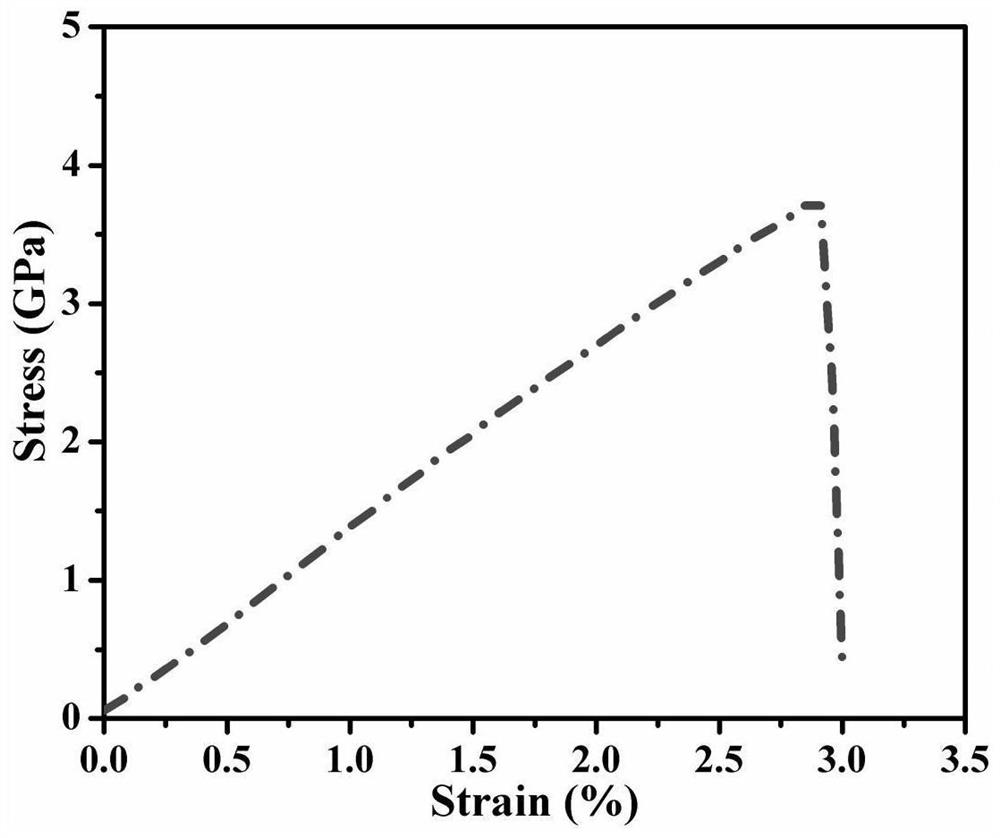

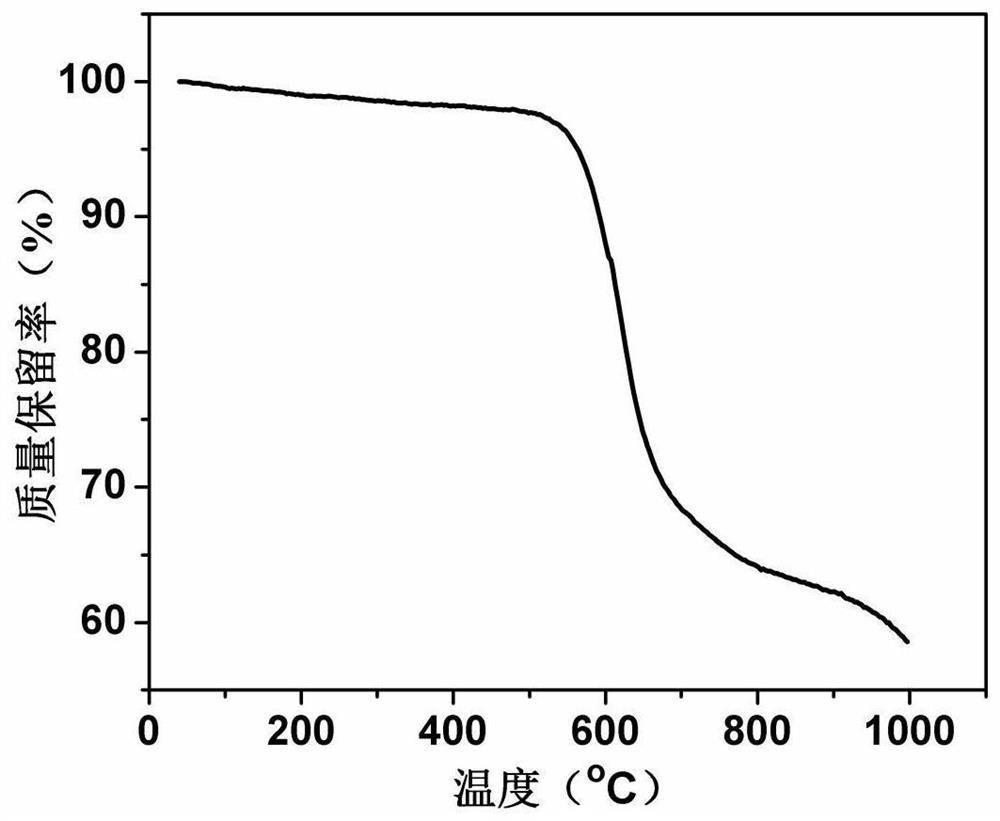

ActiveCN113622049AEvenly dispersedEnhanced hydrogen bondingMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberPolymer science

The invention relates to a preparation method of a high-strength weather-resistant polyimide fiber. The method comprises the following steps of dissolving a diamine monomer containing benzimidazole and a diamine monomer containing o-hydroxybenzophenone in a solvent, adding a dianhydride monomer, carrying out a random copolymerization reaction, mixing with a zinc salt, carrying out dry spinning on the obtained spinning solution, and carrying out cyclization-drafting integrated treatment. The method can realize continuous preparation, is simple to operate, environment-friendly in process and wide in raw material source, and has a good industrialization prospect; and the prepared polyimide fiber has relatively high mechanical properties, surface activity and weather resistance.

Owner:DONGHUA UNIV +1

Epoxy-resin composite material

The invention discloses an epoxy resin composite material, which is prepared from the following raw materials in parts by weight: epoxy resin, rice straw ash, sodium lauryl sulfate, fumed silicon dioxide, polytetrafluoroethylene, propylene glycol methyl ether acetic acid Ester, o-hydroxybenzophenone, water emulsion polyethylene wax, diethyl terephthalate, polyethylene glycol monomethyl ether, n-butanol, polyvinyl alcohol, appropriate amount of water. Beneficial effects of the invention: the production cost is reduced and the performance of the product is improved, and has the advantages of high mechanical performance, high toughness, excellent tensile performance and bending performance, anti-aging, waterproof and heat preservation, and the like.

Owner:SICHUAN MEIDENG FURNITURE CO LTD

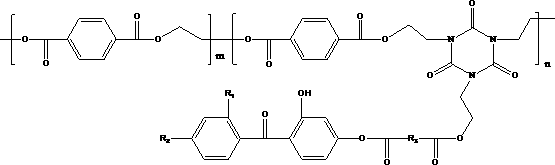

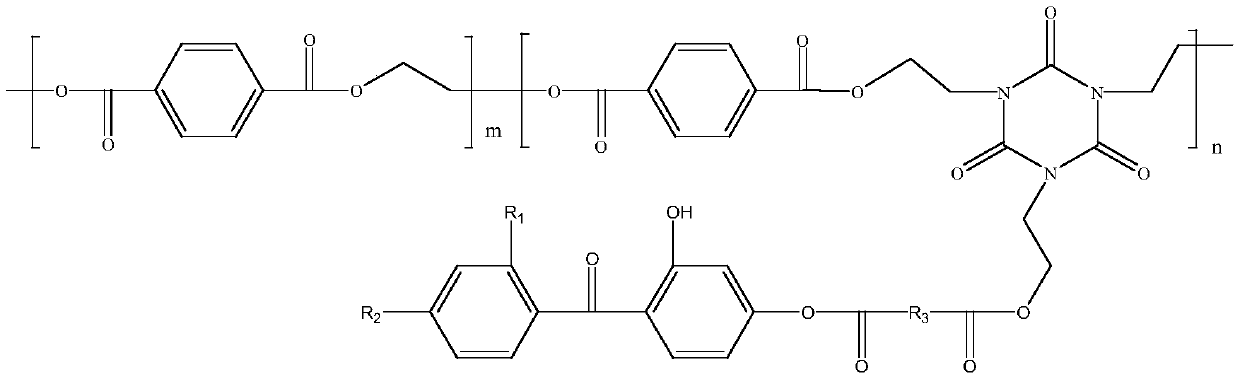

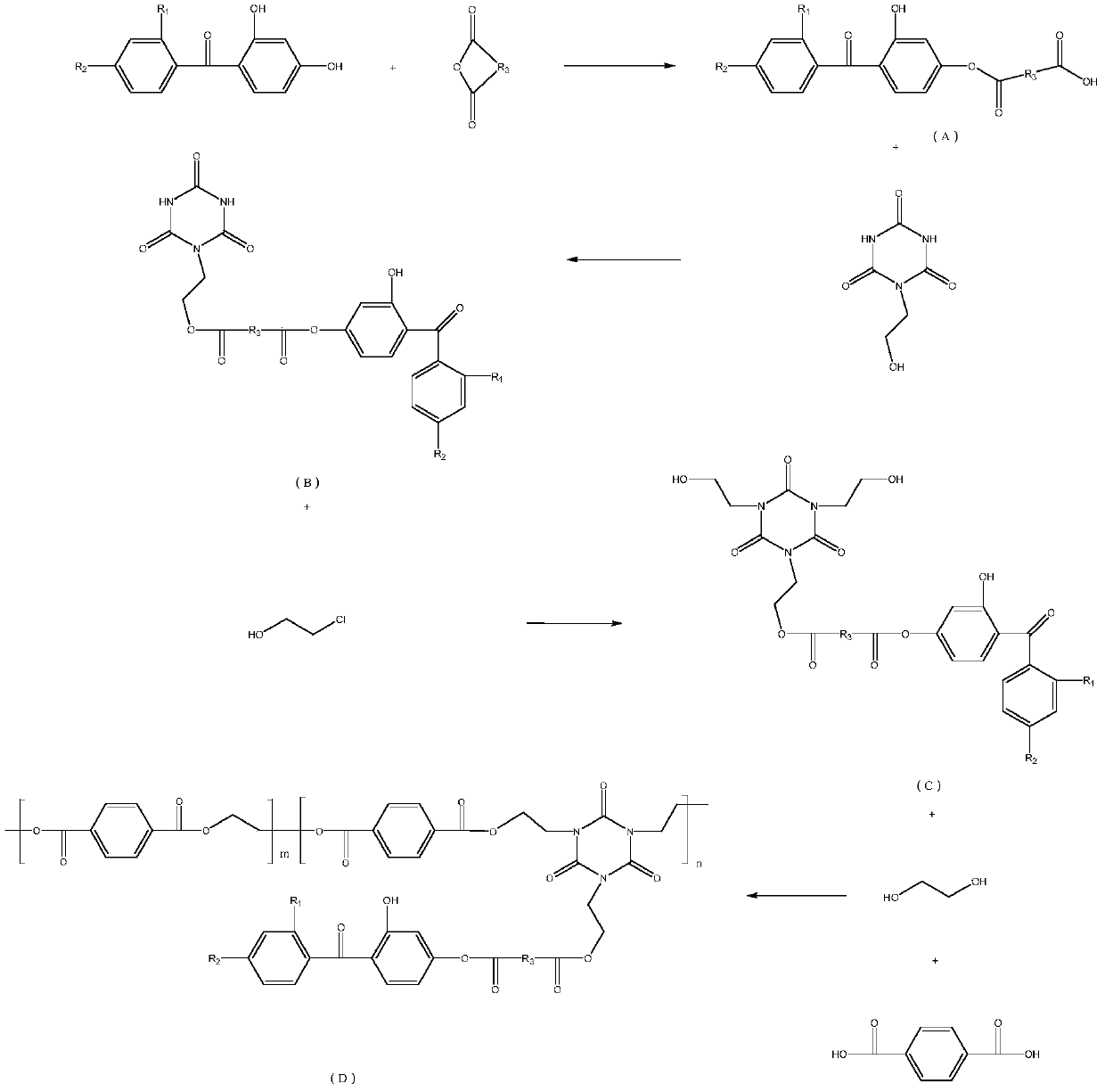

Flame-retardant polyester material, preparation method thereof, granule and fiber product

ActiveCN110878137AHigh reactivityResponsive flexibilityFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPolymer science

The invention discloses a flame-retardant polyester material, a preparation method thereof, a granule and a fiber product. An o-hydroxybenzophenone derivative, acid anhydride, 2-hydroxyethyl isocyanurate, chloroethanol, terephthalic acid and ethylene glycol are used as raw materials, the defect that traditional polyester is inflammable is overcome, and reaction steps are simple and are easy to operate; 2-hydroxyethyl isocyanurate is adopted as one of the raw materials, so that the reaction activity of -OH and-NH2 is high, the reaction flexibility is high, the nitrogen content is high, and theflame retardance of the material is outstanding; the o-hydroxybenzophenone derivative is used as one of the raw materials, the o-hydroxybenzophenone derivative has an ultraviolet absorption effect andcan be used as a light stabilizer, para-hydroxyl groups in the structure can be used as reaction points for esterification, and the contained benzene ring structure is similar to a polyester structure, so good compatibility and facilitation of wide promotion and application are achieved.

Owner:东莞市道尔新材料科技有限公司

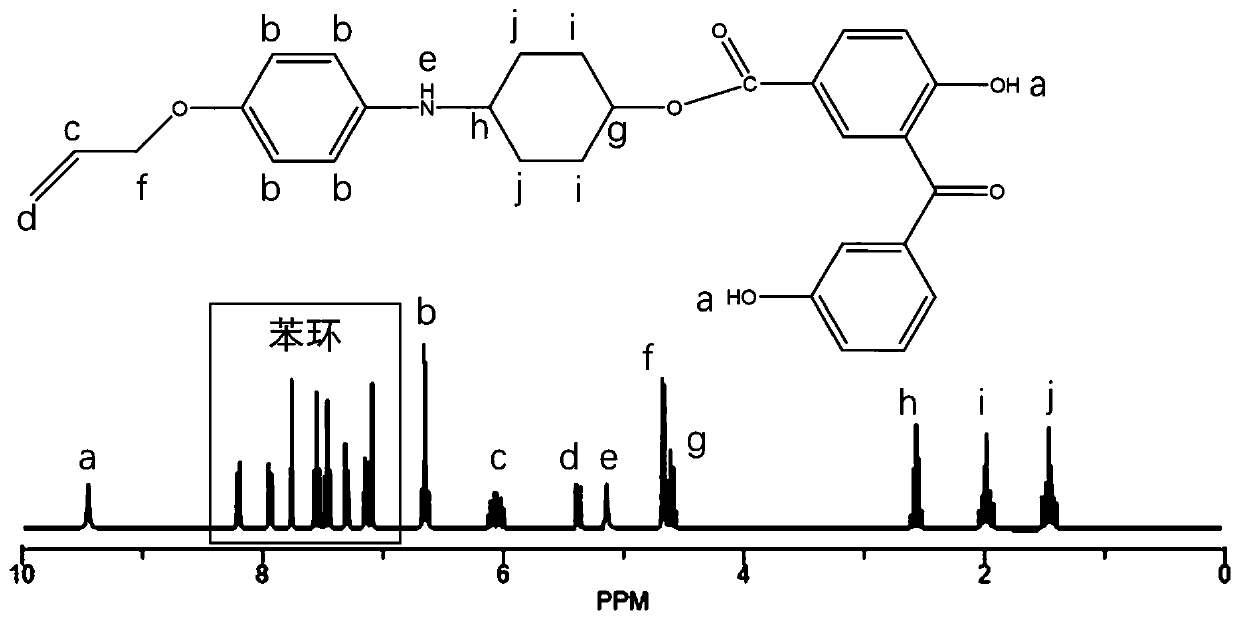

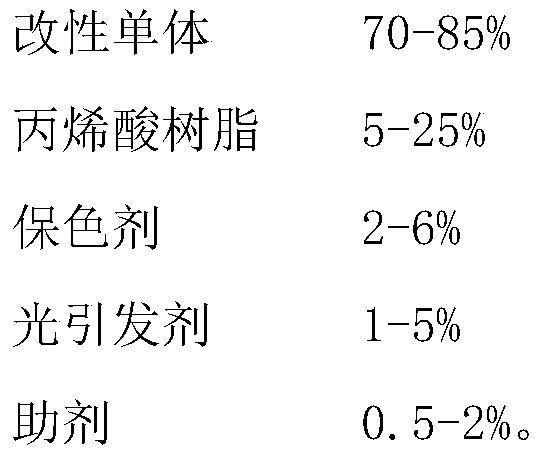

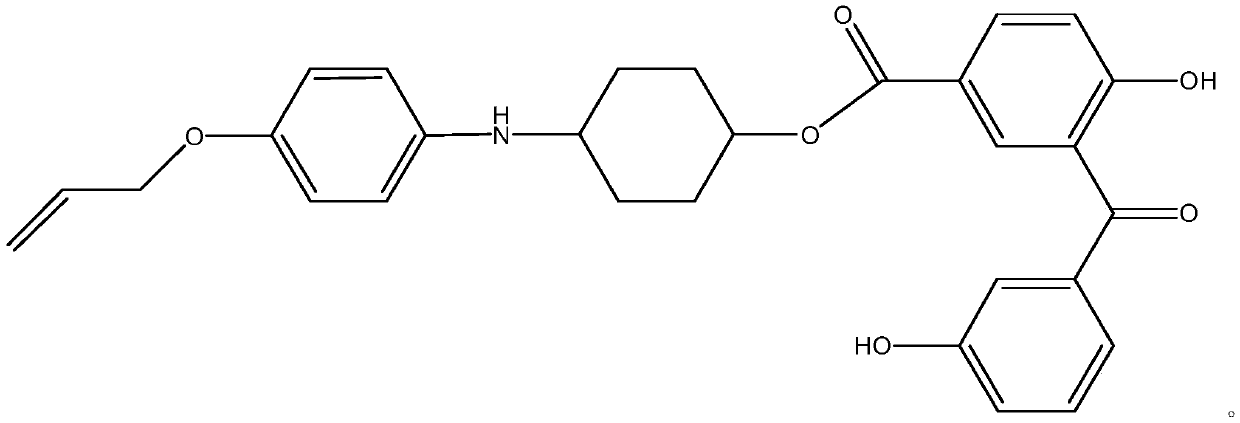

Gloss oil capable of being used for UV printing

ActiveCN110511665AImprove aging resistanceGood colorPolyurea/polyurethane coatingsEpoxy resin coatingsAcrylic resinUltraviolet

The invention belongs to the technical field of UV printing gloss oil, and particularly relates to gloss oil capable of being used for UV printing. The gloss oil is prepared from the following components in percentage by weight: 70-85% of modified monomers, 5-25% of acrylic resin, 2-6% of a color retention agent, 1-5% of a photoinitiator, and 1-5% of an auxiliary. According to the gloss oil capable of being used for UV printing, the color retention agent is added to improve the protective effect against oxygen, heat and ultraviolet aging, the added color retention agent contains both an N-cyclohexyl-p-methoxyaniline structure and an o-hydroxybenzophenone structure, the N-cyclohexyl-p-methoxyaniline structure has good anti-aging performance, the o-hydroxybenzophenone structure can absorb ultraviolet rays and has good stability to light and heat, and the color retention agent is added to the gloss oil to effectively prevent aging of the gloss oil, absorb the ultraviolet rays and protectan printed pattern in the gloss oil, so that the printed pattern can maintain good color and gloss for a long time.

Owner:GUANGDONG HEYGEY LIGHT CURING MATERIALS

Preparation method of a woven bag with strong anti-aging effect

ActiveCN110983473BImprove anti-aging propertiesBag making operationsPaper-makingPolymer scienceStone dust

The invention relates to a preparation method of a woven bag, in particular to a preparation method of a woven bag with strong anti-aging effect. It includes the following steps: mixing stone powder, recycled plastics, color masterbatch, first wood powder, first tourmaline powder, o-hydroxybenzophenone, melting and mixing with β-nucleating agent at a high temperature of 250°C to obtain a molten material, It is extruded through a die to form a plastic film, and the water tank is cooled to set the temperature; the film is stretched; the smear liquid is prepared, and the porous powder quartz powder, the second tourmaline powder, the second wood powder, acrylic emulsion and water are mixed and stirred evenly to get the smear Apply the smear liquid evenly on the surface of the obtained film, and heat the smeared film at 150°C for 1 to 3 minutes to dry; pass the smeared film through a wire drawing unit to make silk thread into a silk ingot, weave it into a woven bag tube cloth, and machine sew into woven bags. The invention uses stone powder, wood powder and tourmaline powder to improve the anti-aging effect of recycled plastics made into woven bags.

Owner:福清市洪裕塑胶有限公司

Method for preparing anti-aging coating for numerical-control machine tools

InactiveCN109575705AGood anti-aging performanceEasy to usePolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyNumerical control

The invention discloses a method for preparing anti-aging coating for numerical-control machine tools. The anti-aging coating comprises, by weight, 20-40 parts of anti-aging coating base solution and30-100 parts of anti-aging additives. The anti-aging coating can be obtained after the anti-aging coating base solution and the anti-aging additives are uniformly mixed with one another. The anti-aging coating base solution comprises, by weight, 30-90 parts of epoxy resin and 40-60 parts of polyvinyl chloride resin. The epoxy resin and the polyvinyl chloride resin are stirred and mixed with each other, and the anti-aging coating base solution can be obtained after the epoxy resin and the polyvinyl chloride resin are completely stirred. The anti-aging additives comprise, by weight, 2-6 parts ofpotassium methyl silanol, 6-10 parts of ortho-hydroxybenzophenone and 1-2 parts of ortho-hydroxybenzotriazole. The potassium methyl silanol, the ortho-hydroxybenzophenone and the ortho-hydroxybenzotriazole are mixed and stirred with one another, then 0.5-2 parts of carbon black are added into the potassium methyl silanol, the ortho-hydroxybenzophenone and the ortho-hydroxybenzotriazole, the carbon black, the potassium methyl silanol, the ortho-hydroxybenzophenone and the ortho-hydroxybenzotriazole are stirred, and the anti-aging additives can be obtained after the carbon black, the potassiummethyl silanol, the ortho-hydroxybenzophenone and the ortho-hydroxybenzotriazole are completely stirred. The method has the advantages that special base solution formulas are adopted, the anti-aging additives with diversified components are used, the anti-aging coating is prepared by the aid of the repeated stirring method, accordingly, good anti-aging effects can be realized by the anti-aging coating prepared by the aid of high-temperature heating processes, and the operational performance of the numerical-control machine tools can be greatly improved.

Owner:ZHEJIANG BUSINESS TECH INST

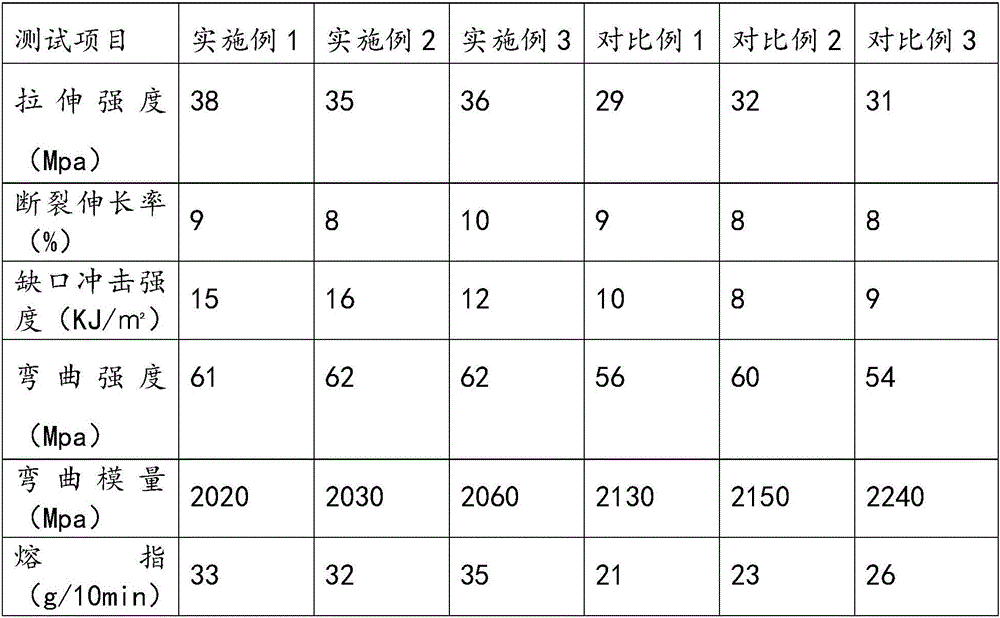

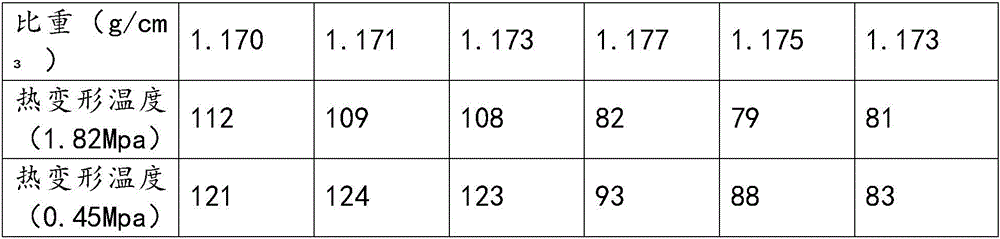

Heat-resistant and flame-retardant composition and preparation method thereof

InactiveCN106189052AImprove heat resistanceBalance of Mechanical PropertiesPolymer scienceAcrylonitrile

The invention relates to a heat-resistant and flame-retardant composition and a preparation method thereof. The heat-resistant and flame-retardant composition is prepared from, by weight, 50-80 parts of ABS resin, 30-35 parts of a flame retardant, 10-15 parts of a flame retardant synergist, 35-45 parts of a heat-resistant modifier, 0.1-2 parts of zinc stearate, 1-10 parts of butadiene-acrylonitrile rubber, 0.1-1 part of p-phenylenediamine and 0.1-1 part of o-hydroxydiphenylketone, wherein the flame retardant synergist is a compound prepared from aluminum hydroxide, mica powder and polysiloxane with the ultra-high molecular weight. According to the technical scheme, the heat-resistant and flame-retardant composition provided through reasonable proportioning and combination of all the components has the high heat resistance, the heat deformation temperature can reach 120 DEG C or above and is at least increased by 30 DEG C compared with the prior art, the achieved flame-retardant effect and stability are better on the premise that the mechanical properties are met, and all the mechanical properties keep optimal balance; in addition, the preparation method is simple, easy to operate and easy to process, the cost is reduced, and the preparation method is suitable for being applied and popularized on market.

Owner:GUILIN HAOXIN TECH SERVICE

A varnish that can be used for uv printing

ActiveCN110511665BImprove aging resistanceGood colorPolyurea/polyurethane coatingsEpoxy resin coatingsPhotoinitiatorOrganic chemistry

The invention belongs to the technical field of UV printing varnish, and specifically relates to a varnish that can be used for UV printing. Agent 2-6%, Photoinitiator 1-5%, Auxiliary 1-5%. The present invention improves the protective effect on oxygen, heat and ultraviolet aging by adding a color-retaining agent, and the added color-retaining agent contains N-cyclohexyl-p-methoxyaniline structure and o-hydroxybenzophenone structure at the same time, wherein The structure of N-cyclohexyl p-methoxyaniline has good anti-aging performance, the structure of o-hydroxybenzophenone can absorb ultraviolet rays, and has good light and thermal stability. Adding this color retaining agent to varnish can effectively prevent light The oil ages, absorbs ultraviolet rays, and protects the printed pattern inside the varnish, so that the printed pattern can maintain good color and luster for a long time.

Owner:GUANGDONG HEYGEY LIGHT CURING MATERIALS

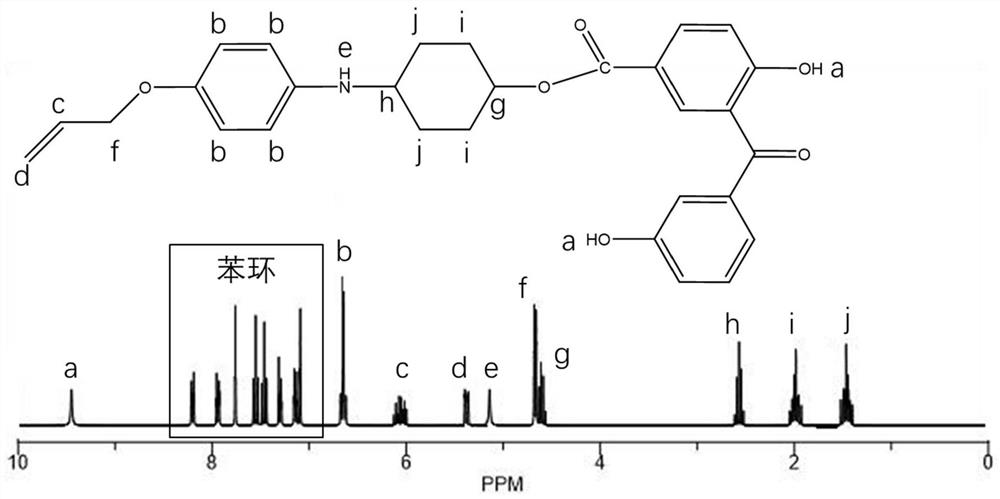

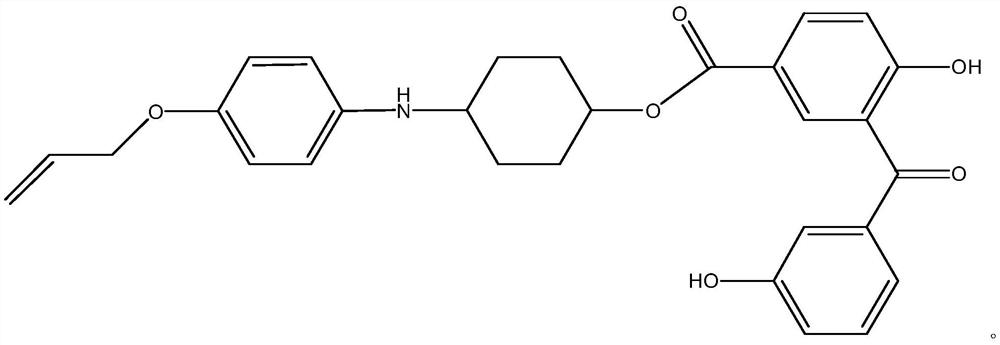

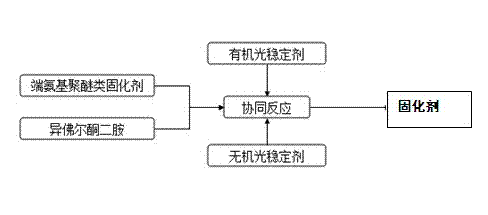

Process for preparing curing agent for high-power light-emitting diode (LED) packaging material

The invention discloses a process for preparing a curing agent for a high-power light-emitting diode (LED) packaging material. The process comprises the following steps of: mixing amino-terminated polyether curing agents and isophorone diamine to obtain a mixed solution; and adding ortho-hydroxybenzophenone and benzotriazole ultraviolet absorbing agents, hindered amine light stabilizers and nano-SiO2 into the mixed solution for synergistic reaction to obtain the required curing agent. The amino-terminated polyether curing agents used in the process have the advantages of colorlessness, transparency, low viscosity, low vapor pressure, high content of primary amine and the like, but the reaction time is relatively long; and the curing agent, namely the isophorone diamine is added into the amino-terminated polyether curing agents in order to accelerate reaction speed and not reduce the performance of a cured object, and then a flexible chain segment of the isophorone diamine can be bonded into a compact epoxy resin cross-linking network, so that the toughness of epoxy resin can be well improved, and a curing product cannot crack easily.

Owner:唐来江

Composite for road barrier

The invention discloses a composite for a road barrier. The composite comprises the following raw materials: polypropylene resin, a modified antiaging agent, polyethylene resin, phthalic acid ester, o-hydroxybenzophenone, a silane coupling agent, diethyl aluminum hypophosphite and white carbon black. The modified antiaging agent is added and has good compatibility with the polypropylene resin andother raw materials; damage to a resin matrix due to ultraviolet rays can be effectively reduced; aging degradation caused by molecular chain breakage of the resin matrix is retarded; and aging resistance and mechanical properties of the composite are greatly improved.

Owner:芜湖盈奇塑业有限公司

A kind of polyimide fiber and preparation method thereof

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com