Ultraviolet-resistant organic silicon adhesive and preparation method thereof

An organic silica gel, UV-resistant technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of complex production process, harsh production conditions, and can not be used normally, saving production time and simplifying production conditions, the effect of good UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

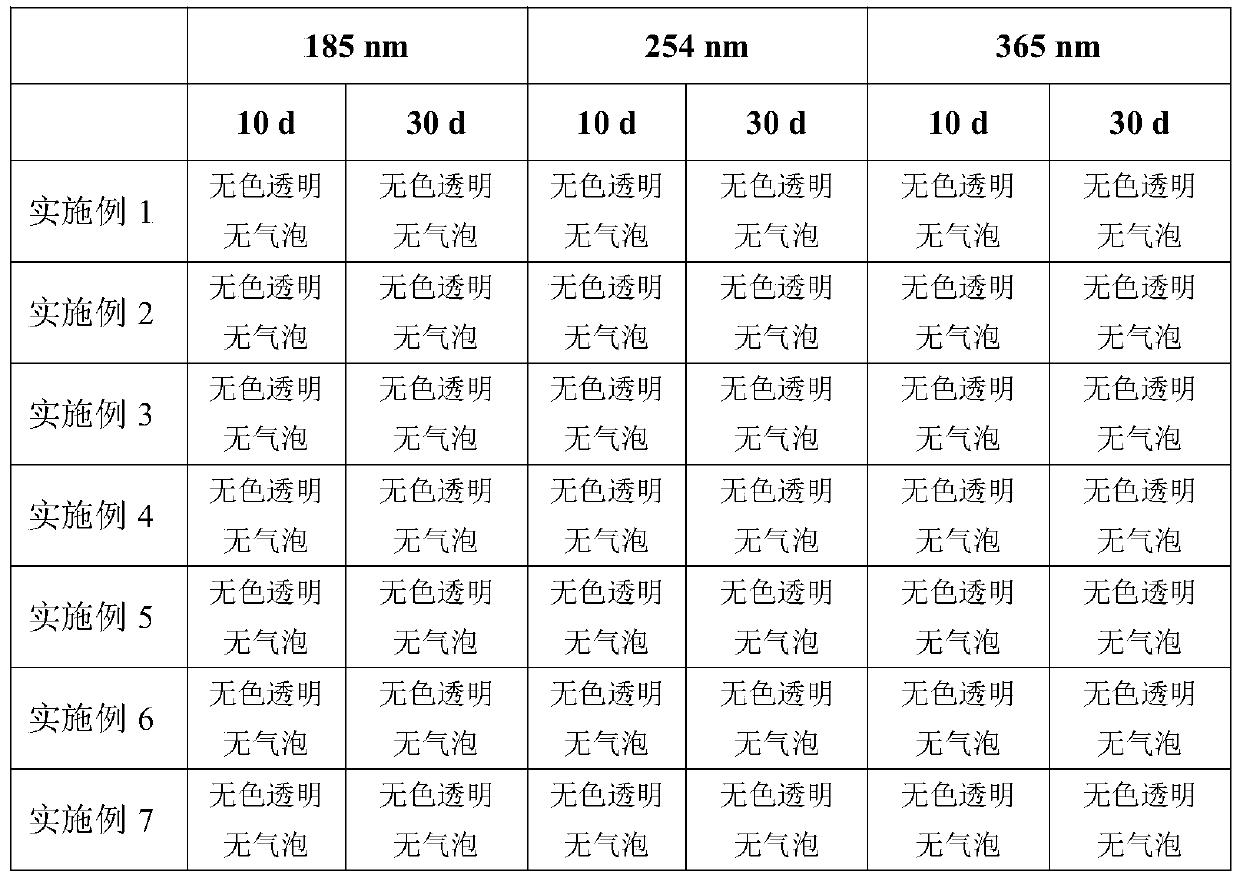

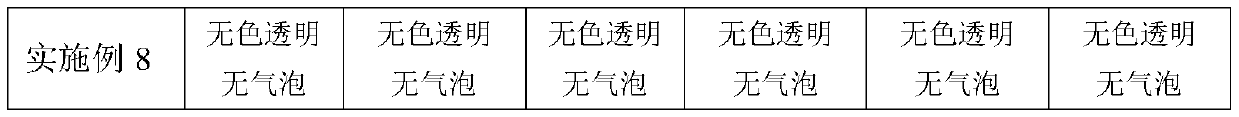

Examples

preparation example Construction

[0024] In the embodiment of the present invention, the preparation method of the UV-resistant silicone adhesive comprises the following steps:

[0025] Step 1, adding epoxy-based ethylenically unsaturated compounds and 400cps to 2000cps terminal vinyl polysiloxane into an open container for stirring, then adding polyvinyl polysiloxane and platinum catalyst, and continuing to stir to obtain The mixture was filtered to remove impurities to obtain component A.

[0026] The specific operation is: weigh in parts by weight: 20 to 50 parts of ethylenically unsaturated epoxy-based compounds, 10 to 18 parts of vinyl-terminated polysiloxanes of 400 cps to 2000 cps, and 0.5 to 18 parts of polyvinyl polysiloxanes. 1 part and 0.009 to 0.1 parts of platinum catalyst; add the ethylenic unsaturated compound of epoxy group and vinyl-terminated polysiloxane into the stirring tank of the mixer in turn, and stir mechanically at the speed of 40rpm / min~60rpm / min 4h~5h, then add polyvinyl polysilox...

Embodiment 1

[0042] Step 1, prepare component A, weigh in parts by weight: 20 parts of allyl ethylene glycol monoglycidyl ether, 10 parts of 400 cps vinyl-terminated vinyl methylpolysiloxane, 0.5 parts of polydimethylsiloxane part and 0.009 part of tetramethyltetravinyl cyclotetrasiloxane complex of chloroplatinic acid; add allyl glycol monoglycidyl ether and terminal vinyl methyl polysiloxane into an open stirring tank Stir, and mechanically stir for 5 hours at a speed of 40 rpm / min to 60 rpm / min, then add polydimethylsiloxane and chloroplatinic acid tetramethyltetravinylcyclotetrasiloxane complex, and continue stirring for 2 hours; Filter the obtained mixture from the stirred tank through a 300-mesh filter under normal pressure to remove impurities, and put it into a finished product barrel to obtain component A.

[0043] Step 2, prepare component B, weighed in parts by weight: 25 parts of 400 cps terminal vinyl methyl polysiloxane, 16 parts of terminal hydrogen polysiloxane with a hydro...

Embodiment 2

[0046] Step 1, prepare component A, weigh in parts by weight: 30 parts of allyl propylene glycol monoglycidyl ether, 17 parts of 800 cps vinyl-terminated polymethylpolysiloxane, 0.7 part of polydimethylsiloxane and 0.009 part of tetramethyl tetravinyl cyclotetrasiloxane complex of chloroplatinic acid; allyl propylene glycol monoglycidyl ether and terminal vinyl methyl polysiloxane are added in an open stirring tank and stirred, Stir mechanically at a speed of 40rpm / min to 60rpm / min for 5h, then add polydimethylsiloxane and chloroplatinic acid tetramethyltetravinylcyclotetrasiloxane complex, and continue stirring for 2h; the resulting mixture Remove impurities from the stirred tank by filtering through a 300-mesh filter under normal pressure, and put it into a finished product barrel to obtain component A.

[0047] Step 2, prepare component B, weigh in parts by weight: 35 parts of 400 cps terminal vinyl methyl polysiloxane, 12 parts of terminal hydrogen polysiloxane with a hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com