Polyimide composite foam precursor powder and polyimide composite foam

A technology of polyimide and composite foam, which is applied in the field of polyimide composite foam precursor powder and polyimide composite foam, which can solve the problem of less research on composite foam, poor mechanical properties of composite foam, and limited composite foam. Application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

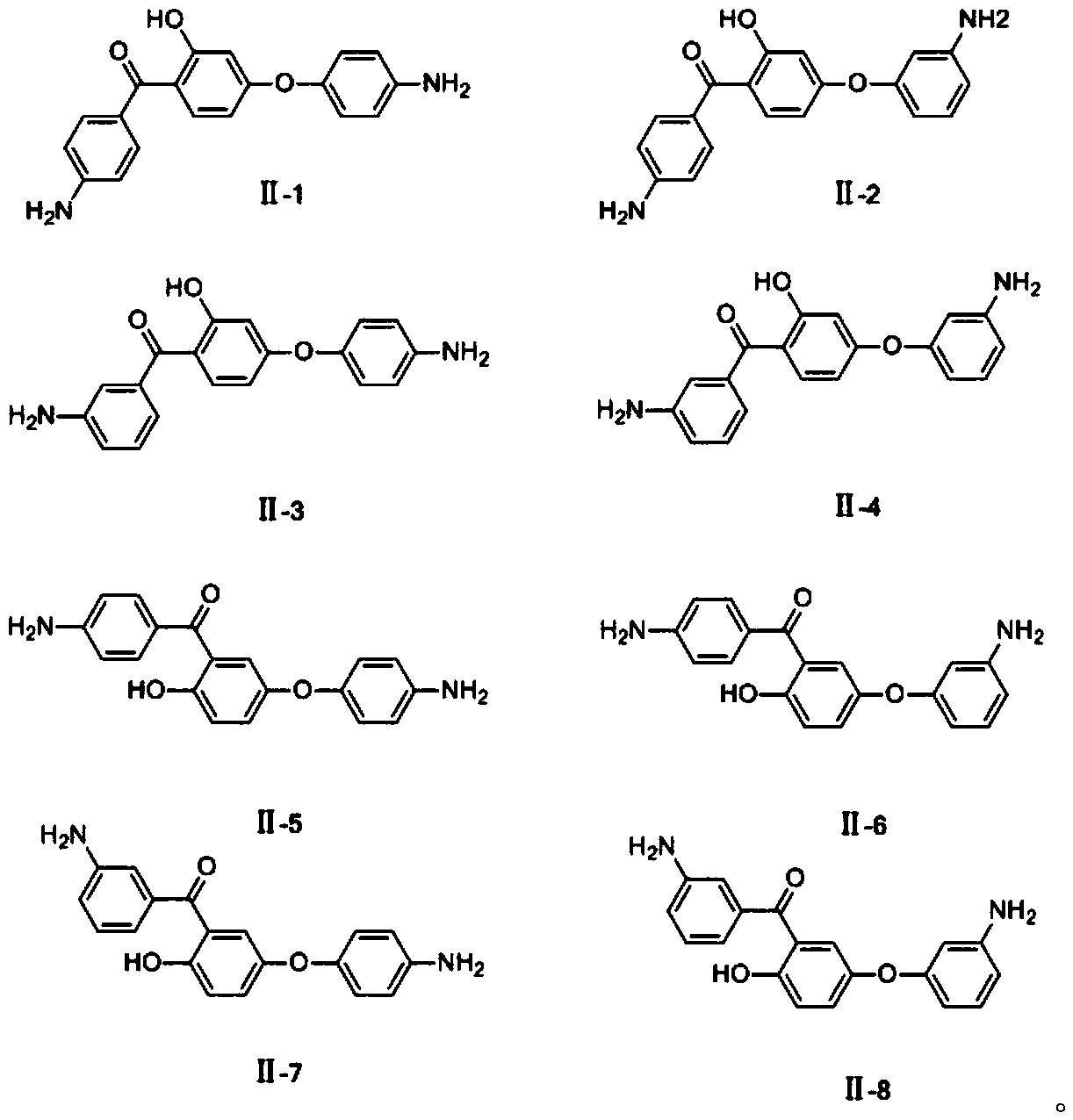

[0056] Add 49.97g (0.096mol) of bisphenol A diether dianhydride and 9.73g (0.09mol) of m-phenylenediamine to a three-necked round-bottomed flask equipped with mechanical stirring, nitrogen protection, water and condensing reflux device, the formula 3.20 g (0.01 mol) of diamine with the structure shown in II-1, 1.18 g (0.008 mol) of terephthalic anhydride, and 350 g of N,N-dimethylacetamide (DMAc) were reacted at room temperature for 12 hours to obtain polyamide acid solution.

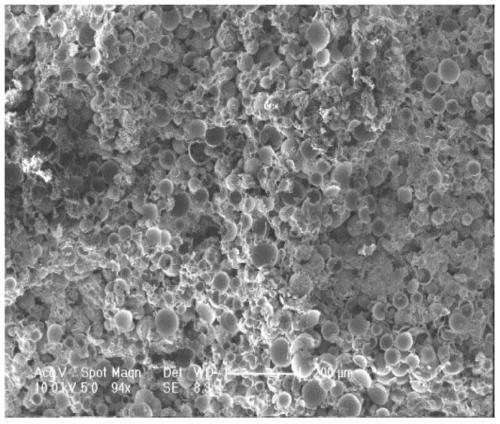

[0057] Add 100g of xylene and 60.5g of hollow glass microspheres to the obtained polyamic acid solution, reflux at 150°C with water for 3 hours, wash with ethanol for 4 times after filtering, dry at 150°C for 10 hours, and crush through 60 mesh After sieving, white hollow microsphere polyimide composite intermediate powder is finally obtained.

[0058] Put the intermediate powder into the mold and transfer it to a flat vulcanizer, raise the temperature to 160°C and keep it for 15 minutes, add 2MPa pres...

Embodiment 2

[0062] Add 49.97g (0.096mol) of bisphenol A diether dianhydride and 9.73g (0.09mol) of m-phenylenediamine to a three-necked round-bottomed flask equipped with mechanical stirring, nitrogen protection, water and condensing reflux device, the formula 3.20 g (0.01 mol) of diamine with the structure shown in II-1, 1.18 g (0.008 mol) of terephthalic anhydride, and 350 g of N, N-dimethylacetamide (DMAc) were reacted at room temperature for 12 hours to obtain polyamide acid solution.

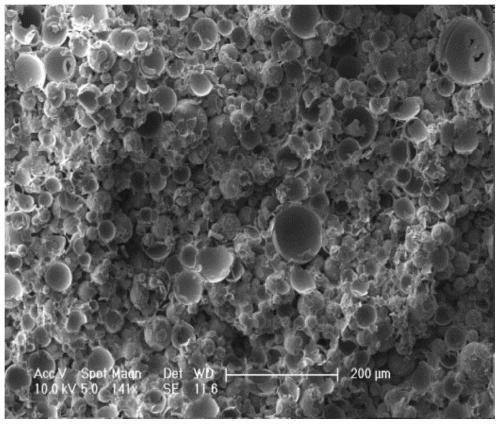

[0063] Add 150g of xylene and 122g of hollow glass microspheres to the obtained polyamic acid solution, reflux at 150°C with water for 3 hours, wash with ethanol for 4 times after filtering, dry at 150°C for 10 hours, and break through a 60-mesh sieve Finally, white hollow microsphere polyimide composite intermediate powder is obtained.

[0064] Put the intermediate powder into the mold and transfer it to a flat vulcanizer, raise the temperature to 160°C and keep it for 20 minutes, add 2MPa pressure t...

Embodiment 3

[0068] Add 49.97g (0.096mol) of bisphenol A diether dianhydride and 9.73g (0.09mol) of p-phenylenediamine to a three-necked round-bottomed flask equipped with mechanical stirring, nitrogen protection, water and condensing reflux device, the formula 3.20 g (0.01 mol) of diamine with the structure shown in II-2, 1.18 g (0.008 mol) of terephthalic anhydride, 350 g of N, N-dimethylacetamide (DMAc), and react at room temperature for 12 hours to obtain polyamide acid solution.

[0069] Add 100g of xylene and 60.5g of hollow ceramic microspheres to the obtained polyamic acid solution, reflux with water at 150°C for 3 hours, wash with ethanol for 4 times after filtering, dry at 150°C for 10 hours, and crush through 60 mesh After sieving, white hollow microsphere polyimide composite intermediate powder is finally obtained.

[0070] Put the intermediate powder into the mold and transfer it to a flat vulcanizer, raise the temperature to 180°C and keep it for 15 minutes, add 5MPa pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com