Polyimide composite foam precursor powder and polyimide composite foam

A polyimide and syntactic foam technology, applied in the field of polyimide syntactic foam precursor powder and polyimide syntactic foam, can solve the problem of poor mechanical properties of syntactic foam, less research on syntactic foam, and limitation of syntactic foam application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

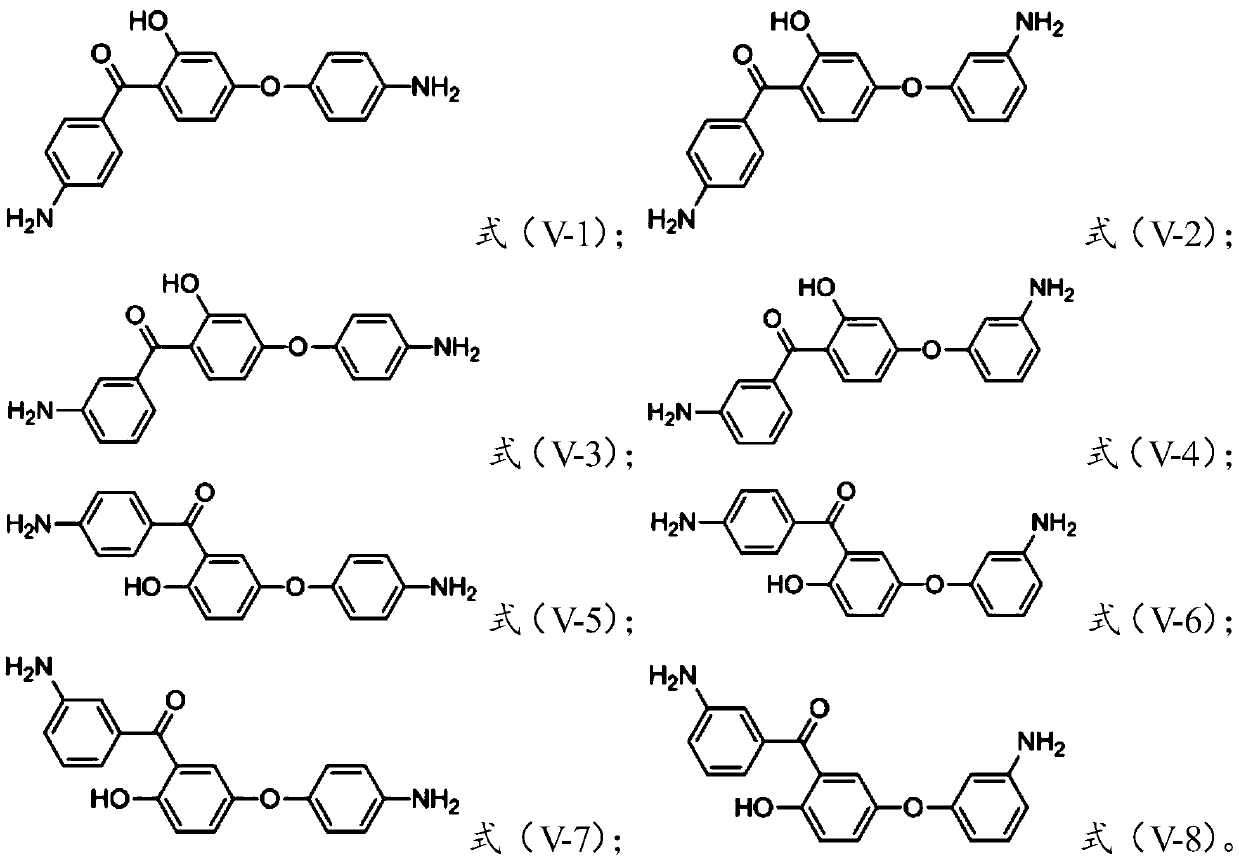

Method used

Image

Examples

Embodiment 1

[0135] (1) Add 69.52g (0.56mol) of 3-methoxyphenol, 88.23g (0.56mol) of p-nitrochlorobenzene, 85.14g (0.616mol) of potassium carbonate and 200g of dimethyl sulfoxide into the reactor in sequence , heated to 160°C and reacted for 6h; cooled to 60°C, added to 2000mL water, precipitated crude product, filtered out, dissolved in dichloromethane after washing, dried over anhydrous magnesium sulfate, concentrated solvent, obtained crude product again, and re- Crystallization obtained 114.23 g of the refined product of compound (II-1) represented by formula (II); the yield was 83.2%.

[0136] Utilize nuclear magnetic resonance to characterize the structural compound (II-1) shown in the formula (II) that obtains, the proton nuclear magnetic resonance spectrum result that obtains is: 1 H NMR (400MHz, DMSO) δ = 8.280–8.205 (m, 2H), 7.389 (t, J = 8.2Hz, 1H), 7.170–7.095 (m, 2H), 6.875 (dd, J = 8.3Hz, 2.2Hz , 1H), 6.776(t, J=2.2Hz, 1H), 6.731(dd, J=8.0Hz, 2.0Hz, 1H), 3.765(s, 3H).

[01...

Embodiment 2

[0144] (1) Referring to step (1) of Preliminary Example 1, the refined product of the compound (II-1) shown in formula (II) was obtained.

[0145] (2) 18.56g (0.1mol) 3-nitrobenzoyl chloride, 14.67g (0.11mol) aluminum trichloride, 250g 1,2-dichloroethane and 22.07g (0.09mol) formula (II) Compounds (II-1) showing the structure were sequentially added into the reactor, stirred and reacted at 20°C for 30 h; then slowly added to ice-hydrochloric acid for treatment, separated, dried over anhydrous magnesium sulfate, and concentrated solvent to obtain a crude product, which was subjected to Recrystallization obtained 21.02 g of refined product of compound (III-3) represented by formula (III); the yield was 59.2%.

[0146] Utilize nuclear magnetic resonance to characterize the structural compound (III-3) shown in the formula (III) that obtains, the proton nuclear magnetic resonance spectrum result that obtains is: 1 H NMR (400MHz, DMSO) δ=8.490(d, J=8.0Hz, 1H), 8.425(s, 1H), 8.312(d...

Embodiment 3

[0152] (1) Add 69.52g (0.56mol) of 4-methoxyphenol, 88.23g (0.56mol) of p-nitrochlorobenzene, 85.14g (0.616mol) of potassium carbonate and 200g of dimethyl sulfoxide into the reactor in sequence , heated to 160°C and reacted for 6h; cooled to 60°C, added to 2000mL water, precipitated crude product, filtered out, dissolved in dichloromethane after washing, dried over anhydrous magnesium sulfate, concentrated solvent, obtained crude product again, and re- Crystallization obtained 117.56 g of a refined product of compound (II-3) represented by formula (II); the yield was 85.6%.

[0153] (2) 89.07g (0.48mol) 4-nitrobenzoyl chloride, 69.34g (0.52mol) aluminum trichloride, 1000mL dichloromethane and 105.45g (0.43mol) structure compound (II) shown in formula (II) -3) Added to the reactor in turn, stirred and reacted at 30°C for 15h; then slowly added to ice-hydrochloric acid for treatment, separated liquid, dried over anhydrous magnesium sulfate, concentrated the solvent to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com