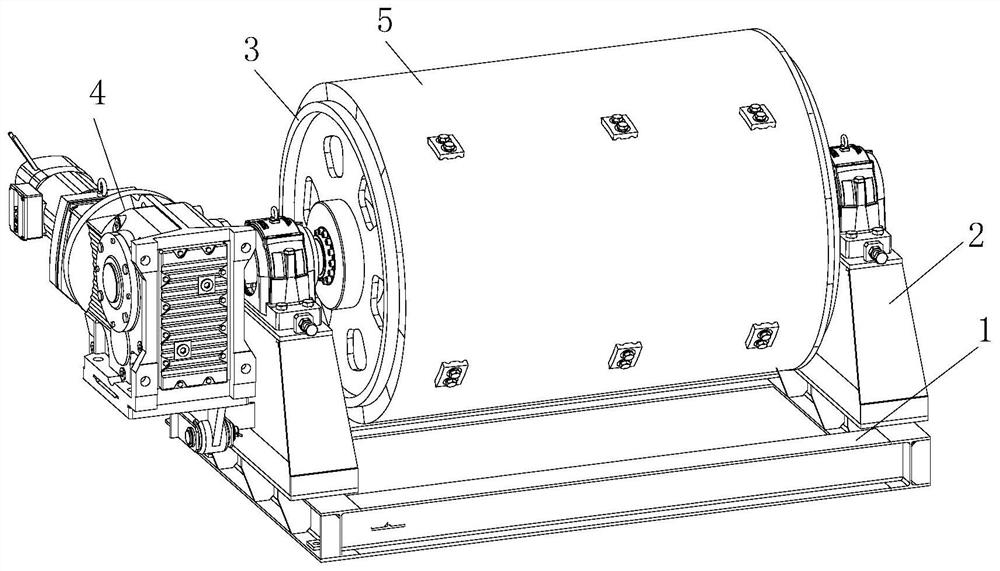

Novel masterbatch composite additive and production process thereof

A technology of composite additives and masterbatch, which is applied in the field of masterbatch composite additives, can solve the problems of bottom impact affecting the grinding effect, achieve the effects of ensuring grinding efficiency and effect, improving grinding level, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

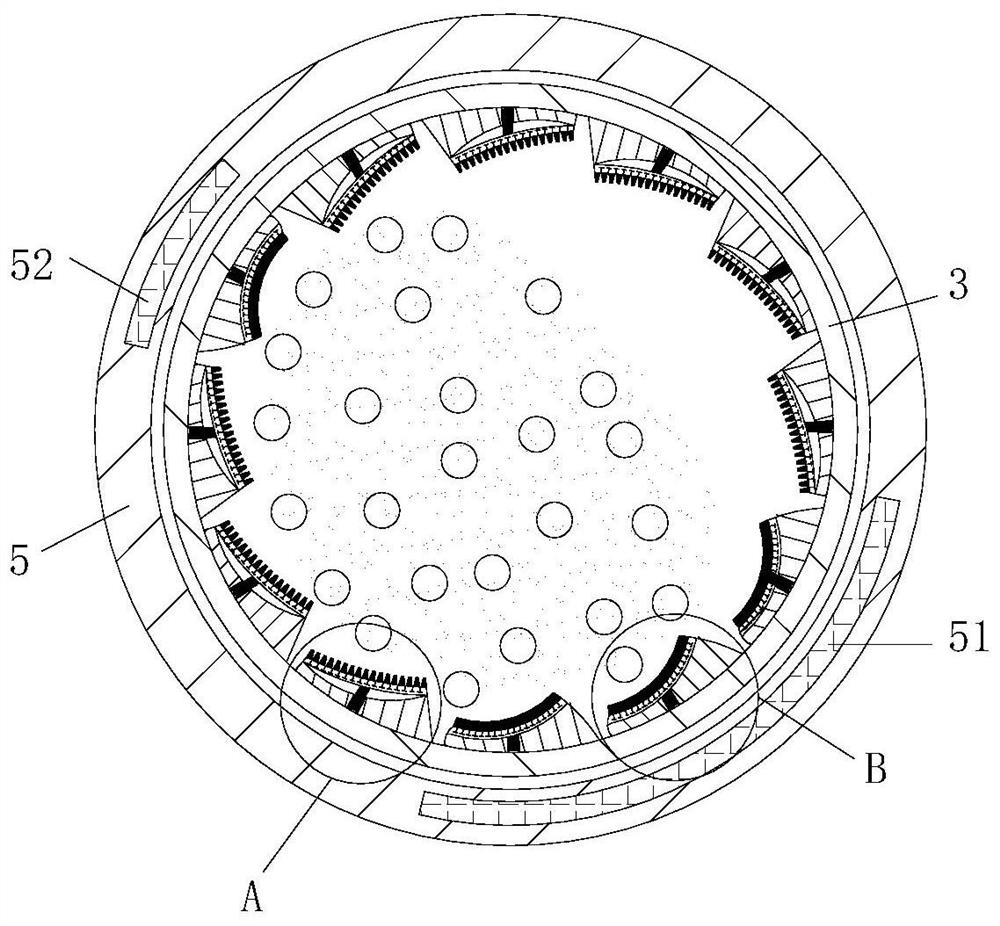

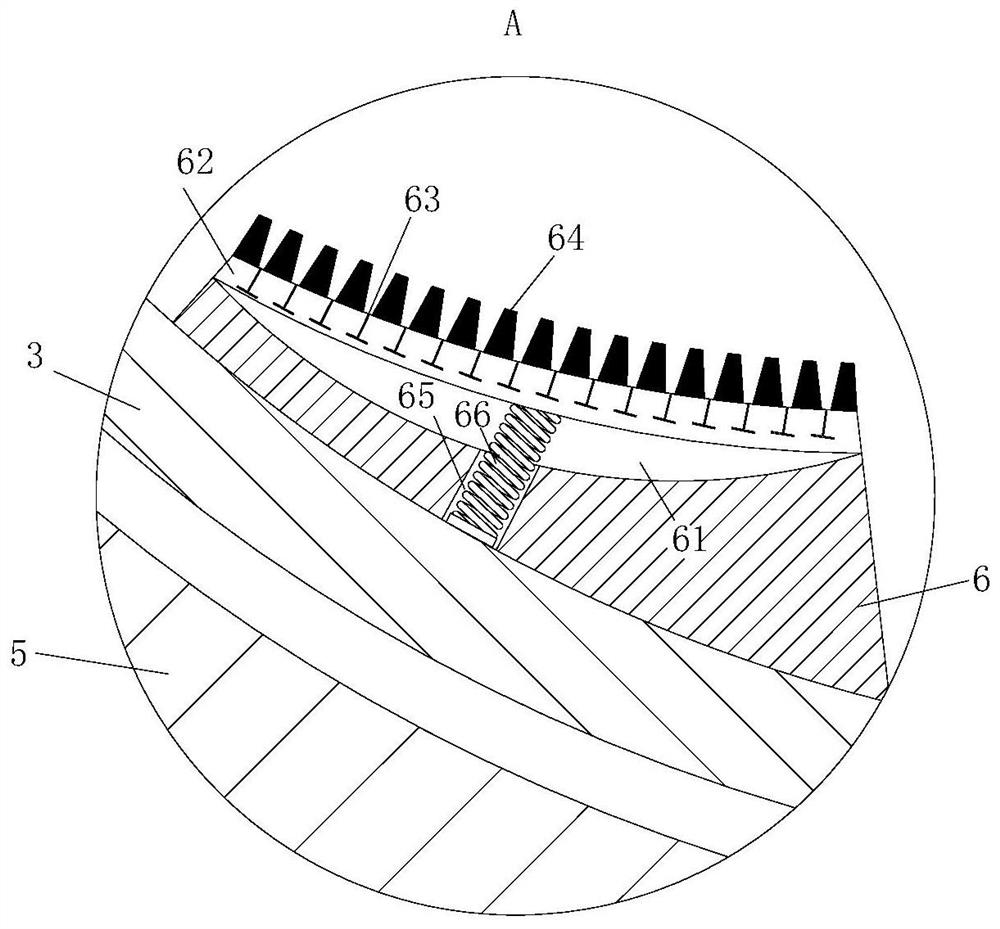

[0035] As an embodiment of the present invention, a stainless steel shrapnel 62 is fixedly connected between the inner two ends of the arc surface 61 of the lining plate 6, and the stainless steel shrapnel 62 is bent toward the arc surface 61 and its radius of curvature is larger than that of the arc. The radius of curvature of the shaped surface 61. The elastic potential energy of the deformation of the stainless steel shrapnel 62 is used to store the impact energy received at the lower part of the inner cylinder 3, and release the elastic potential energy when it rotates to the upper left side of the inner cylinder 3, reducing energy loss and improving the separation of grinding media Increase the initial velocity of the liner 6, thereby increasing its inertial force, and improving the crushing and grinding effects.

[0036] As an embodiment of the present invention, the stainless steel shrapnel 62 is provided with T-shaped chapped grooves 63 at intervals, and the inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com