Preparation method of napkin paper product with high-precision artistic patterns

A high-precision, table paper technology, applied in separation methods, chemical instruments and methods, filter paper, etc., can solve the problems of poor antibacterial effect, low pattern accuracy, difficult processing, etc., to improve antibacterial performance, simple preparation process, overall The effect of structural stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

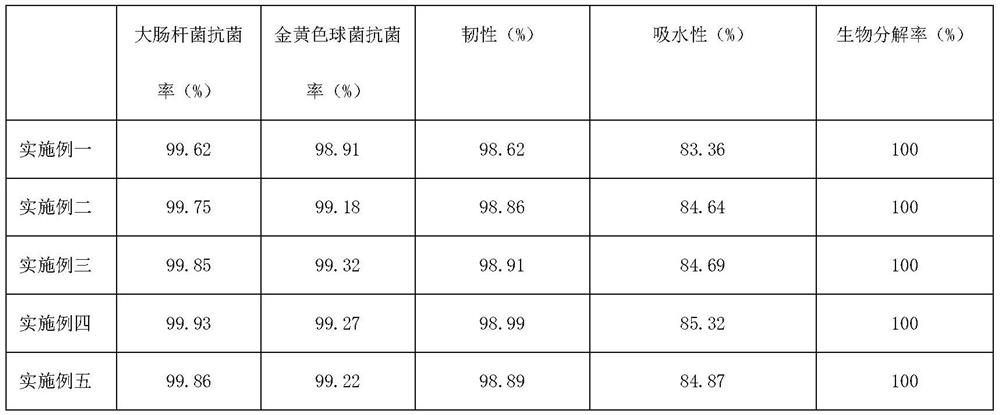

Embodiment 1

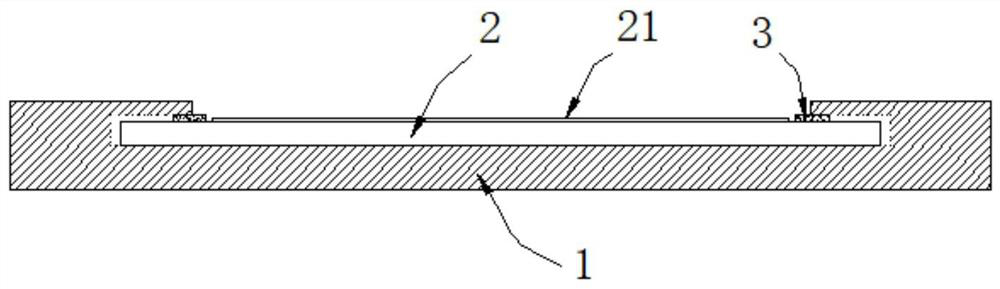

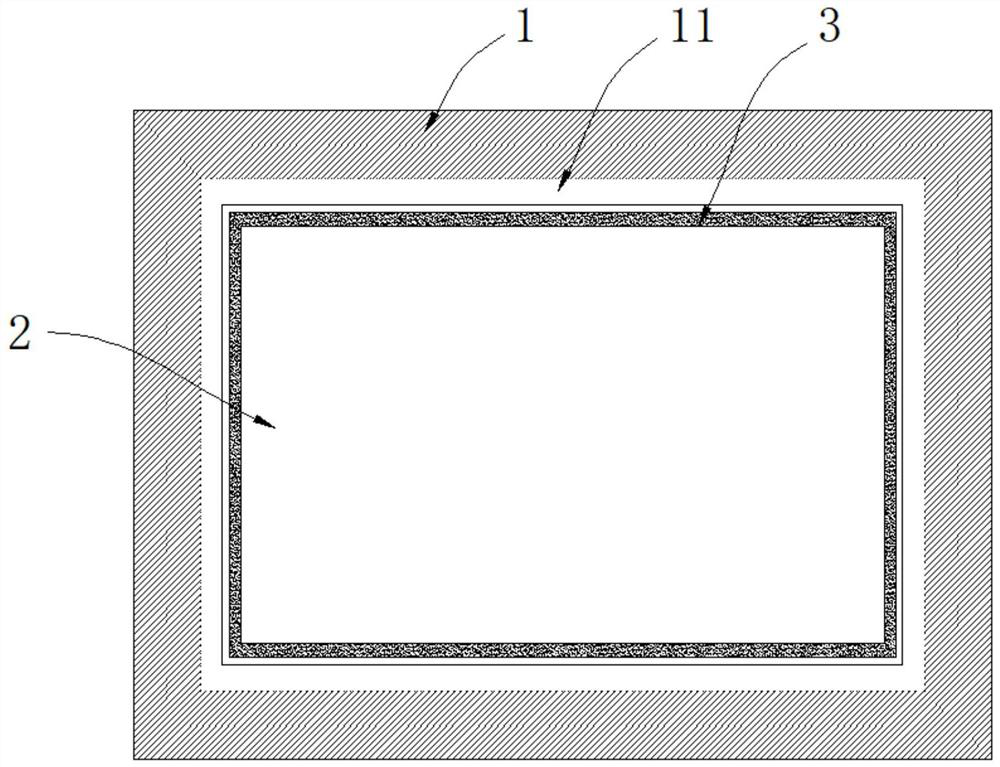

[0023] A method for preparing a table paper product with high-precision artistic patterns proposed by the present invention, comprising a table paper carrier 1, a water-soluble film 2 and a sealing layer 3;

[0024] The table paper carrier 1 includes the following components by weight: 60 parts of pulp, 45 parts of polylactic acid, 20 parts of modified nano-montmorillonite, 18 parts of PEG-40 hydrogenated castor oil, 18 parts of hydrophilic polymer, anion 15 parts of polyacrylamide, 15 parts of perlite powder, 16 parts of sweet-scented osmanthus extract, 12 parts of mugwort leaf extract, 10 parts of o-hydroxybenzophenone derivatives, 9 parts of graphene oxide, 3 parts of antibacterial agent, pulp, Polylactic acid, modified nano-montmorillonite, PEG-40 hydrogenated castor oil, perlite powder, and graphene oxide powder were evenly mixed in parts by weight and then placed in a beater for 2 physical beatings. The first beater used 800r / min speed for initial beating for 1h, and th...

Embodiment 2

[0026] A method for preparing a table paper product with high-precision artistic patterns proposed by the present invention, comprising a table paper carrier 1, a water-soluble film 2 and a sealing layer 3;

[0027] The table paper carrier 1 includes the following components by weight: 65 parts of pulp, 48 parts of polylactic acid, 21 parts of modified nano-montmorillonite, 19 parts of PEG-40 hydrogenated castor oil, 19 parts of hydrophilic polymer, anion 16 parts of polyacrylamide, 16 parts of perlite powder, 17 parts of sweet-scented osmanthus extract, 13 parts of mugwort leaf extract, 11 parts of o-hydroxybenzophenone derivatives, 10 parts of graphene oxide, 4 parts of antibacterial agent, pulp, Polylactic acid, modified nano-montmorillonite, PEG-40 hydrogenated castor oil, perlite powder, and graphene oxide powder were evenly mixed in parts by weight and then placed in a beater for 2 physical beatings. / min speed initial beating for 1.2h, the second beater beat at a speed ...

Embodiment 3

[0029] A method for preparing a table paper product with high-precision artistic patterns proposed by the present invention, comprising a table paper carrier 1, a water-soluble film 2 and a sealing layer 3;

[0030]The table paper carrier 1 includes the following components by weight: 70 parts of pulp, 51 parts of polylactic acid, 22 parts of modified nano-montmorillonite, 20 parts of PEG-40 hydrogenated castor oil, 19 parts of hydrophilic polymer, anion 17 parts of polyacrylamide, 17 parts of perlite powder, 17 parts of sweet-scented osmanthus extract, 14 parts of mugwort leaf extract, 12 parts of o-hydroxybenzophenone derivatives, 11 parts of graphene oxide, 5 parts of antibacterial agent, pulp, Polylactic acid, modified nano-montmorillonite, PEG-40 hydrogenated castor oil, perlite powder, and graphene oxide powder were evenly mixed in parts by weight and then placed in a beater for 2 physical beatings. / min speed initial beating for 1.4h, the second beater beating at a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com