Flame-retardant polyester material, preparation method thereof, granule and fiber product

A technology of flame-retardant polyester and pellets, which is applied in the field of polyester materials, can solve problems such as fire accidents, and achieve the effects of easy operation, good compatibility, and widespread application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

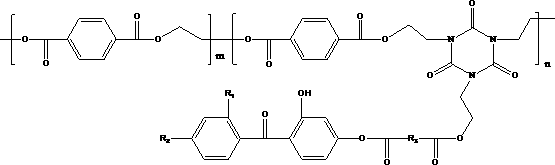

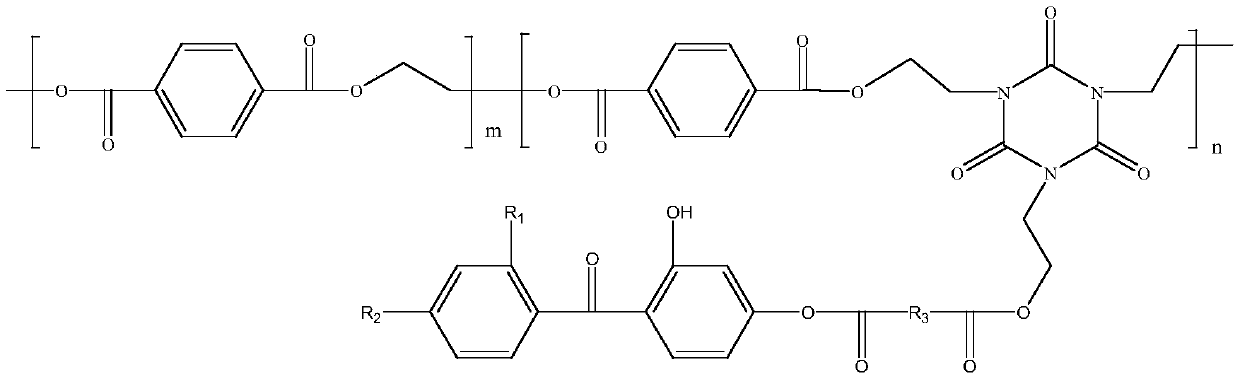

Method used

Image

Examples

Embodiment 1

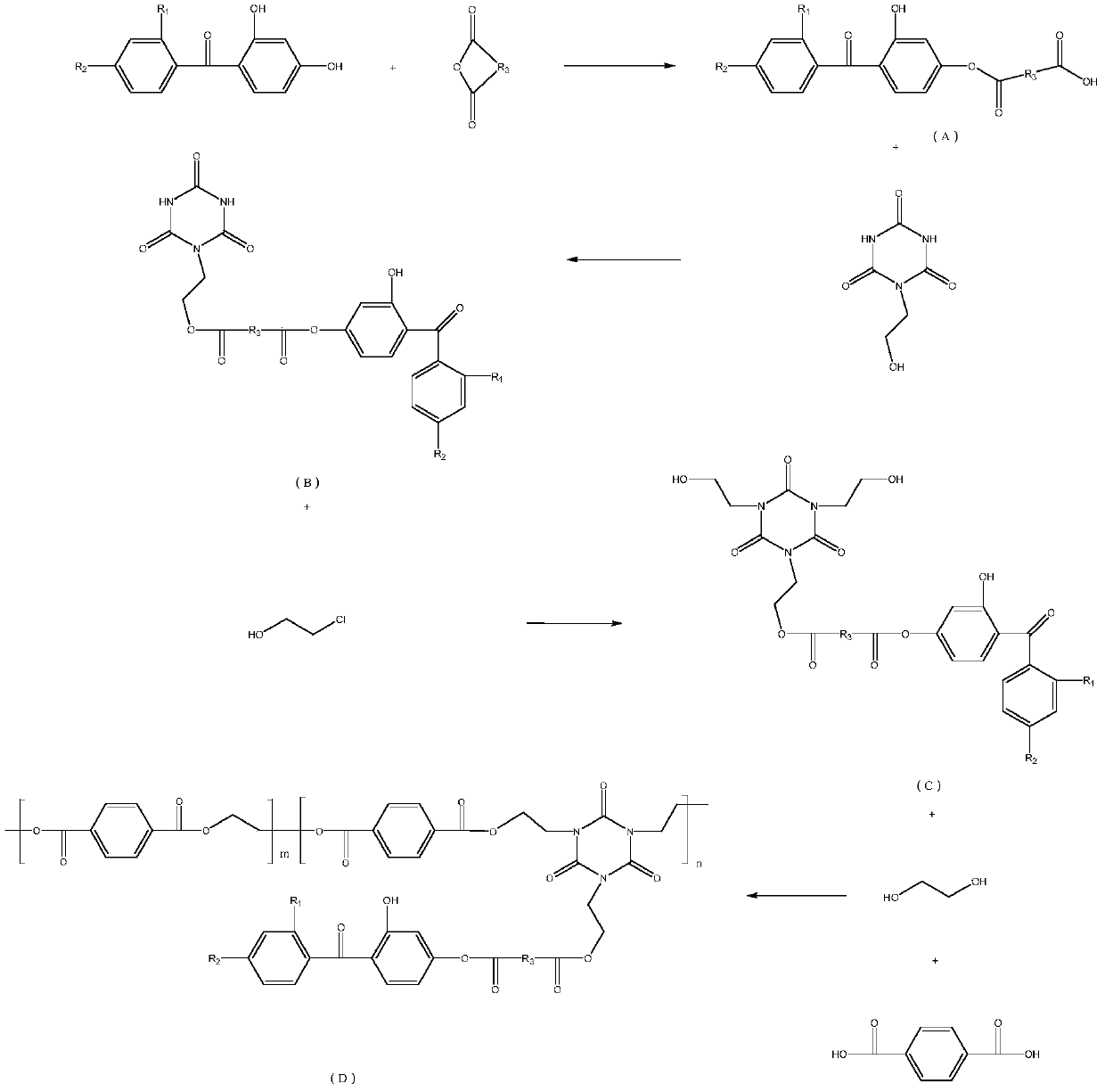

[0028] Embodiment 1: A kind of preparation method of flame-retardant polyester pellet provided in this embodiment, it comprises the following steps:

[0029] (1) 1 part of 2,4-dihydroxybenzophenone derivative (R 1 : -H, R 2 :-H), 1.2 parts of succinic anhydride, 0.01% part of 4-dimethylaminopyridine, and 50 parts of tetrahydrofuran were placed in a three-necked flask, mechanically stirred, heated to reflux for 10 h, left to stand, filtered, and the organic phase was distilled under reduced pressure to obtain terminal Carboxyl benzophenone derivatives (IR: 3352cm -1 : Phenol-OH weakened; 3386cm -1 : -OH generation; 1780cm -1 : Ring-C=O disappears; 1750cm -1 :-C=O generates), be recorded as A;

[0030] (2) Put 1 part of A, 1.2 parts of hydroxyethyl isocyanurate, 0.01% part of 4-dimethylaminopyridine, and 60 parts of tetrahydrofuran in a three-necked flask, mechanically stir, heat and reflux for 10 hours, let stand, filter, The organic phase was distilled under reduced pres...

Embodiment 2

[0033] Embodiment 2: A kind of preparation method of flame-retardant polyester pellet provided in this embodiment, it comprises the following steps:

[0034] (1) 1 part of 2,4-dihydroxybenzophenone derivative (R 1 : -H, R2 :-OCH 3 ), 1.0 parts of phthalic anhydride, 5% parts of zinc acetate, and 50 parts of acetone are placed in a three-necked flask, mechanically stirred, heated to reflux for 15h, left to stand, filtered, and the organic phase is distilled under reduced pressure to obtain the carboxyl-terminated diphenylmethane Ketone derivatives (IR: 3352cm -1 : Phenol-OH weakened; 3386cm -1 : -OH generation; 1780cm -1 : Ring-C=O disappears; 1750cm -1 :-C=O generates), be recorded as A;

[0035] (2) Put 1 part of A, 1.0 part of hydroxyethyl isocyanurate, 5% part of zinc acetate, and 60 parts of acetone in a three-necked flask, mechanically stir, heat and reflux for 20 hours, let stand, filter, and decompress the organic phase After distillation and vacuum drying, isocya...

Embodiment 3

[0038] Embodiment 3: A kind of preparation method of flame-retardant polyester pellet provided in this embodiment, it comprises the following steps:

[0039] (1) 1 part of 2,4-dihydroxybenzophenone derivative (R 1 : -OH, R 2 :-OC 2 h 5 ), 1.1 parts of succinic anhydride, 1% part of antimony trioxide, 50 parts of N,N-dimethylformamide were placed in a three-necked flask, mechanically stirred, heated to reflux for 12h, left to stand, filtered, and the organic phase was distilled under reduced pressure , to obtain carboxyl-terminated benzophenone derivatives (IR: 3352cm -1 : Phenol-OH weakened; 3386cm -1 : -OH generation; 1780cm -1 : Ring-C=O disappears; 1750cm -1 :-C=O generates), be recorded as A;

[0040] (2) Put 1 part of A, 1.1 parts of hydroxyethyl isocyanurate, 1% part of antimony trioxide, and 60 parts of N,N-dimethylformamide in a three-necked flask, stir mechanically, and heat to reflux for 15 hours , stand still, filter, the organic phase is distilled under red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com