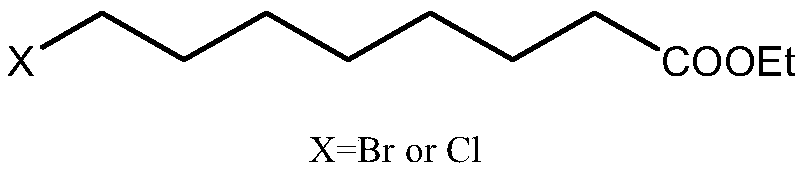

Method for recycling by-product in preparation process of ethyl 8-halooctanoate

A technology for the preparation process of ethyl octoate, which is applied in the field of recovery and utilization of by-products in the process of ethyl 8-halooctanoate, and can solve the problem that the former fraction cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

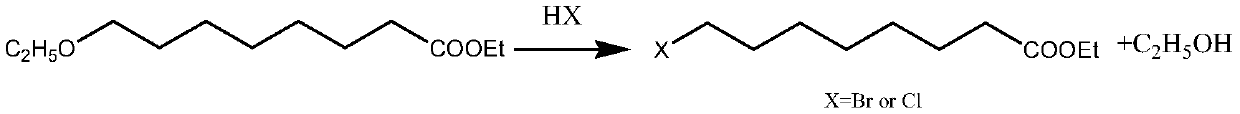

Method used

Image

Examples

Embodiment 1

[0016] In a 500mL three-necked flask, add 80 grams of ethyl 8-halooctanoate containing by-product ethyl 8-ethoxyoctanoate (12% content of ethyl 8-ethoxyoctanoate), raise the temperature to 130°C, and slowly introduce Hydrogen bromide gas was passed through and stirred at this temperature for 5 hours, cooled to below 30°C, washed with 40ml of water, and analyzed by GC, the purity was 96.8%, and the content of ethyl 8-ethoxyoctanoate was 3.1%.

Embodiment 2

[0018] In a 500mL three-necked flask, add 80 grams of ethyl 8-halooctanoate containing by-product ethyl 8-ethoxyoctanoate (12% content of ethyl 8-ethoxyoctanoate), raise the temperature to 150°C, and slowly introduce Hydrogen bromide gas was passed through and stirred at this temperature for 5 hours, cooled to below 30°C, washed with 40ml of water, and analyzed by GC, the purity was 99.1%, and the content of ethyl 8-ethoxyoctanoate was 0.9%.

Embodiment 3

[0020] In a 500mL three-neck flask, add 80 grams of ethyl 8-halooctanoate (14% content of ethyl 8-ethoxyoctanoate) containing by-product ethyl 8-ethoxyoctanoate, raise the temperature to 130°C, and slowly introduce Hydrogen chloride gas was passed through and stirred at this temperature for 5 hours, cooled to below 30°C, washed with 40ml of water, and analyzed by GC, the purity was 97.8%, and the content of ethyl 8-ethoxyoctanoate was 2.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com