Ultrasonic wave acting method and device

An ultrasonic, action technology, applied in the field of ultrasonic action, to increase the probability of generation, improve water quality, and improve the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

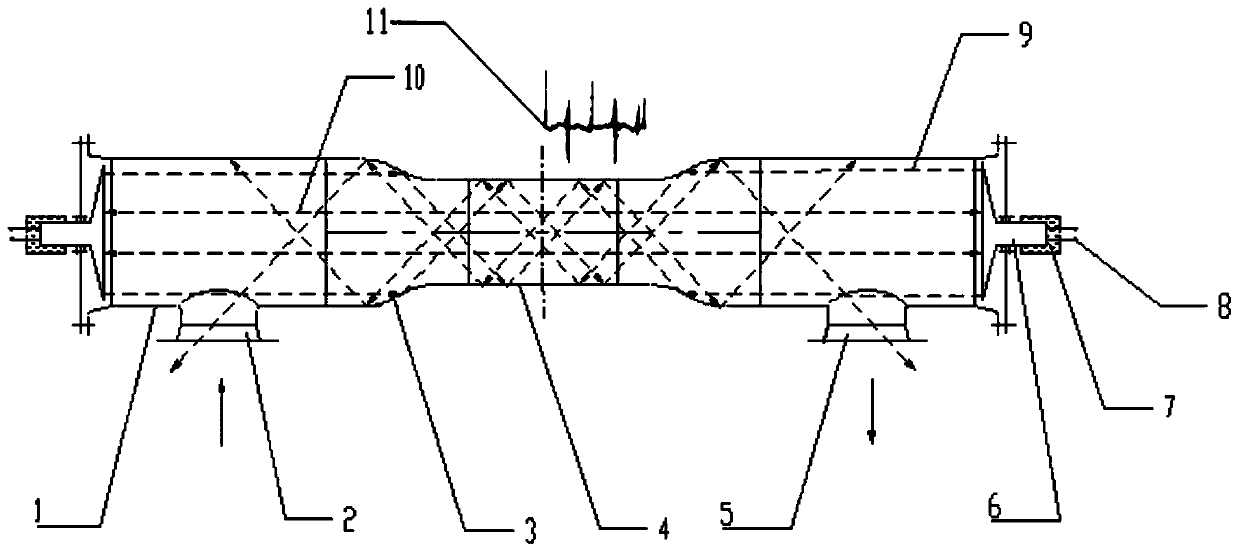

[0057] The method of ultrasonic action in this embodiment is: adopting the mixed action mode of parallel ultrasonic waves and pipeline reflected ultrasonic waves, and superimposing to realize the joint action effect of the standing wave field effect and the ultrasonic propagation without dead angle coverage and infinite extension.

[0058] Wherein, the parallel facing ultrasonic waves 10 are produced by two ultrasonic transducers 6 oppositely arranged at the two ends of the ultrasonic action area, and the parallel facing ultrasonic waves 10 have the same frequency, the same vibration direction, and opposite propagation directions; The ultrasonic wave reflected by the transition inclined pipe 3 is the pipe reflected ultrasonic wave 9, which is then reflected by the pipe structure in the ultrasonic action area to form an ultrasonic action mode in which the parallel opposing ultrasonic waves 10 and the pipe reflected ultrasonic waves 9 are interwoven and mixed.

[0059] figure 1 ...

Embodiment 2

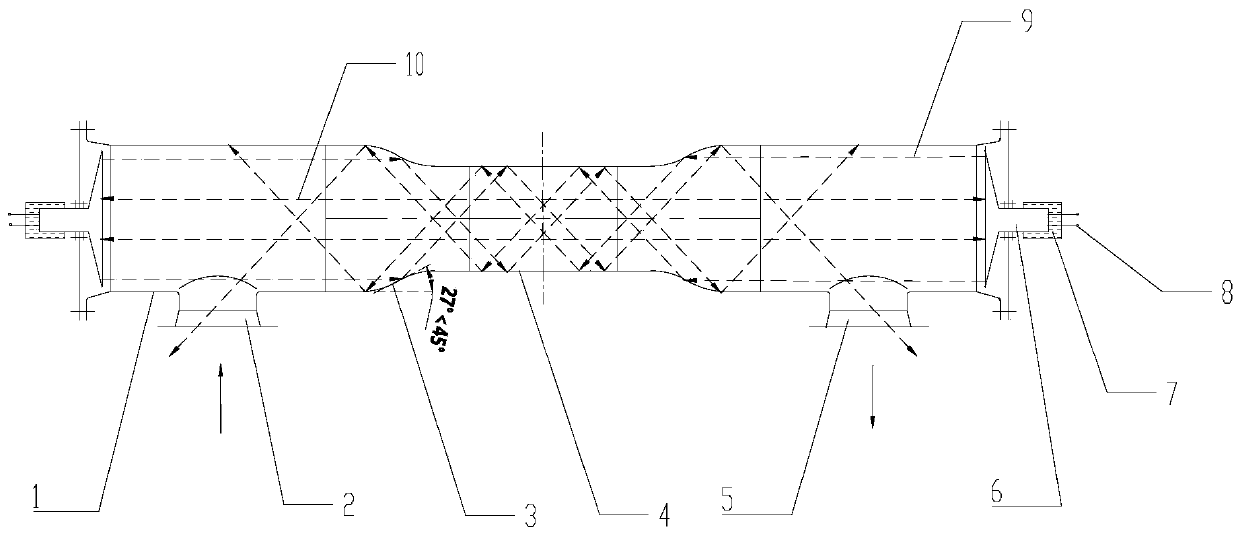

[0077] The ultrasonic action method of this embodiment is included in Embodiment 1, the ultrasonic action method and device of this embodiment, and the included angle of the inclined tube is less than 45°.

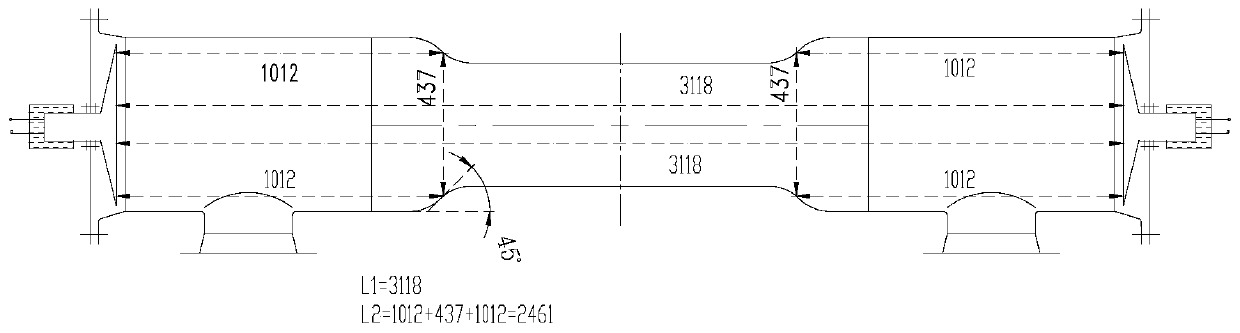

[0078] Such as figure 1 , image 3 , Figure 4 , Figure 5 , the method and device for ultrasonic action described in this embodiment, the method and device for ultrasonic action described in this embodiment, including the action area of a dumbbell-shaped pipeline structure with a thin middle and two thick ends, and an action area of a dumbbell-shaped pipeline structure It includes the large-diameter straight pipe section 1 at both ends and the small-diameter straight pipe section 4 in the middle, the large-diameter straight pipe section 1 and the small-diameter straight pipe section 4 are connected by a transition inclined pipe 3, and the angle between the transition inclined pipe 3 and the straight pipe section is less than 45°; The large-diameter straight pipe se...

Embodiment 3

[0092] The method and device for ultrasonic action in this embodiment are the same as in Embodiment 2, the difference lies in that the angle between the transition inclined pipe 3 and the straight pipe section is greater than 45°.

[0093] Such as Figure 8 , Figure 9 , when the angle between the transition inclined pipe 3 and the straight pipe section is greater than 45°, the propagation of ultrasonic waves is as follows Figure 8 , Figure 9 As shown, after the ultrasonic wave emitted by the ultrasonic transducer 6 is reflected by the transition inclined pipe 3, the ultrasonic wave returns to the large-diameter straight pipe section 1, does not pass through the small-diameter straight pipe section 4 in the middle, and does not reach the large-diameter straight pipe section 1 at the other end. The large-diameter straight pipe section 1 on the side is reflected by the pipe wall, and finally enters the inlet or outlet pipeline through the material inlet 2 and material outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com