A device and method for processing lightweight waste printed circuit boards

A printed circuit board and waste technology, which is applied in the field of devices for processing lightweight waste printed circuit boards, can solve the problems of burning bag production, unstable flue gas, incomplete combustion, etc., and achieve stable production process, prolong residence time, full burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

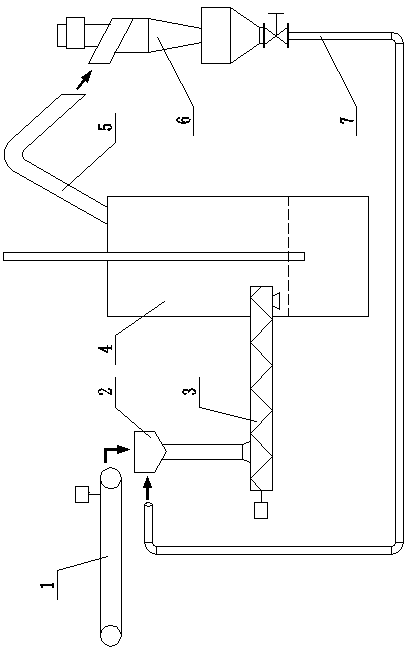

[0039] The raw material used is a light waste printed circuit board, which is a paper substrate with a particle size of less than 20mm, containing 1.36% copper, of which volatile matter accounts for 40.17%, ash content accounts for 52.14%, and fixed carbon accounts for 7.69%.

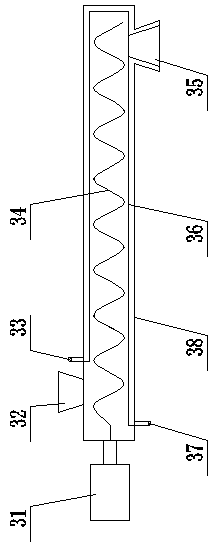

[0040] The incinerator used is a top-blown molten pool melting furnace with an inner diameter of 1.5m and a furnace height of 7.0m. The screw feeder is installed at the lower part of the furnace body of the top-blown molten pool melting furnace at a distance of 900mm from the bottom of the furnace, and the discharge end extends into the inner wall of the furnace by 150mm. The ash return pipe used is made of 310s stainless steel.

[0041] The specific processing implementation steps are as follows:

[0042] (1) After opening the water inlet and outlet valves of the screw feeder 3, start to heat up the incinerator, and when the temperature in the incinerator is 100°C, open the cyclone dust collector 6 and ...

Embodiment 2

[0050] The raw material used is a light-weight waste printed circuit board, which is a glass fiber substrate with a particle size of less than 10mm, containing 5% copper, of which volatile matter accounts for 45.42%, and ash content accounts for 54.58%.

[0051] The incinerator used is a top-blown molten pool melting furnace with an inner diameter of 1.0m and a furnace height of 6.0m. The screw feeder is installed at the lower part of the furnace body of the top-blown molten pool melting furnace at a distance of 600mm from the bottom of the furnace, and the discharge end extends into the inner wall of the furnace by 200mm.

[0052] The feeder used is a belt feeder; the ash return pipe used is made of 309s stainless steel.

[0053] The specific implementation steps are as follows:

[0054] (1) After opening the water inlet and outlet valves of the screw feeder 3, start to heat up the incinerator, and when the temperature in the incinerator is 150°C, turn on the cyclone dust co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com