Fragrance beads

A technology of fragrant beads and essence, applied in the directions of detergent composition fragrance, detergent composition, surface active detergent composition, etc., can solve the problem of mutual adsorption and precipitation of anions and cations, affecting the softening effect of softeners, affecting the decontamination ability of detergents, etc. It can enhance the decontamination ability, reduce the secondary deposition of stains, and improve the effect of continuous fragrance retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

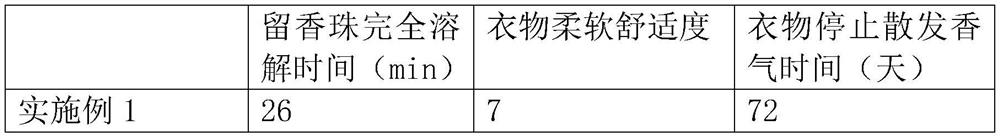

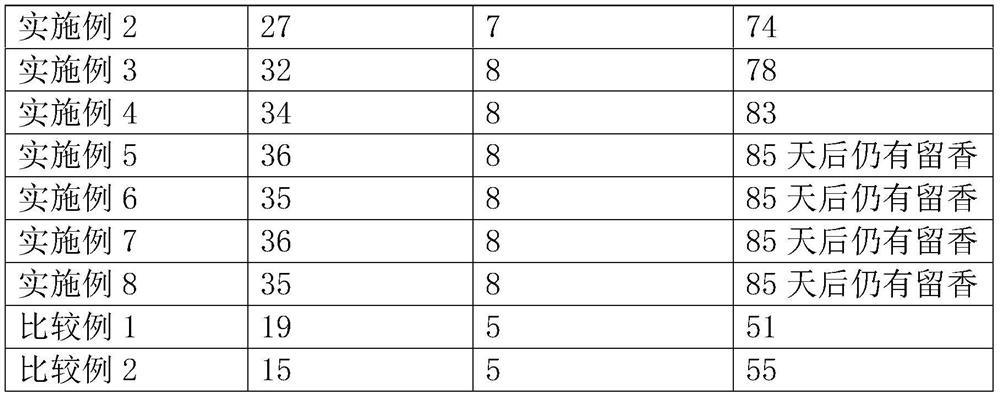

Examples

Embodiment 1

[0053] A kind of fragrance beads, comprising the following components in parts by mass:

[0054] Polyethylene glycol 84kg; silicon dioxide 10kg; essence 6kg; essence microcapsules 11kg; dye 0.4kg.

[0055] In this embodiment, polyethylene glycol of the type PEG-10000 produced by Guangzhou Zhuocen Chemical Co., Ltd. was used.

[0056] A preparation method of fragrant beads, comprising the following steps:

[0057] S1. Add 84 kg of polyethylene glycol into the emulsification pot, heat up to 65°C until the polyethylene glycol becomes a transparent liquid, turn off the heating, and make the constant temperature of the emulsification pot 65°C;

[0058] S2. Add 10 kg of silicon dioxide to the polyethylene glycol, stir and mix until completely dissolved to form a fine paste to form the first mixture;

[0059] S3. Add 0.4 kg of dye to the first mixture, stir and mix until completely dissolved to form the second mixture;

[0060] S4. Add 6 kg of essence and 11 kg of essence microcap...

Embodiment 2

[0062] A kind of fragrance beads, comprising the following components in parts by mass:

[0063] Polyethylene glycol 92kg; silicon dioxide 9kg; essence 11kg; essence microcapsules 7kg; dye 0.3kg.

[0064] In this embodiment, polyethylene glycol of the type PEG-10000 produced by Guangzhou Zhuocen Chemical Co., Ltd. was used.

[0065] A preparation method of fragrant beads, comprising the following steps:

[0066] S1. Add 92kg of polyethylene glycol into the emulsification pot, heat up to 80°C until the polyethylene glycol becomes a transparent liquid, turn off the heating, and make the constant temperature of the emulsification pot 70°C;

[0067] S2. Add 9 kg of silicon dioxide to polyethylene glycol, stir and mix until completely dissolved to form a fine paste to form the first mixture;

[0068] S3. Add 0.3 kg of dye to the first mixture, stir and mix until completely dissolved to form the second mixture;

[0069] S4. Add 11kg of essence and 7kg of essence microcapsules to ...

Embodiment 3

[0071] A kind of fragrance beads, comprising the following components in parts by mass:

[0072] Polyethylene glycol 78kg; silicon dioxide 7kg; essence 1kg; essence microcapsules 6kg; dye 0.05kg.

[0073] In this embodiment, polyethylene glycol of the type PEG-10000 produced by Guangzhou Zhuocen Chemical Co., Ltd. was used.

[0074] A preparation method of fragrant beads, comprising the following steps:

[0075] S1. Add 78kg of polyethylene glycol into the emulsification pot, heat up to 80°C until the polyethylene glycol becomes a transparent liquid, turn off the heating, so that the constant temperature of the emulsification pot is 70°C;

[0076] S2. Add 7 kg of silicon dioxide to the polyethylene glycol, stir and mix until completely dissolved to form a fine paste to form the first mixture;

[0077] S3. Add 0.05 kg of dye to the first mixture, stir and mix until completely dissolved to form the second mixture;

[0078] S4. Add 1 kg of essence and 6 kg of essence microcaps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com