A booster for an aircraft

A supercharging device and aircraft technology, which is applied to parts of elastic fluid pumping devices, machines/engines, non-variable pumps, etc., can solve the problem of small axial size, function and structure that cannot meet the requirements of combined wing aircraft Work requirements, high single-stage booster ratio, etc., to achieve the effect of small axial size, compact structure, and small loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

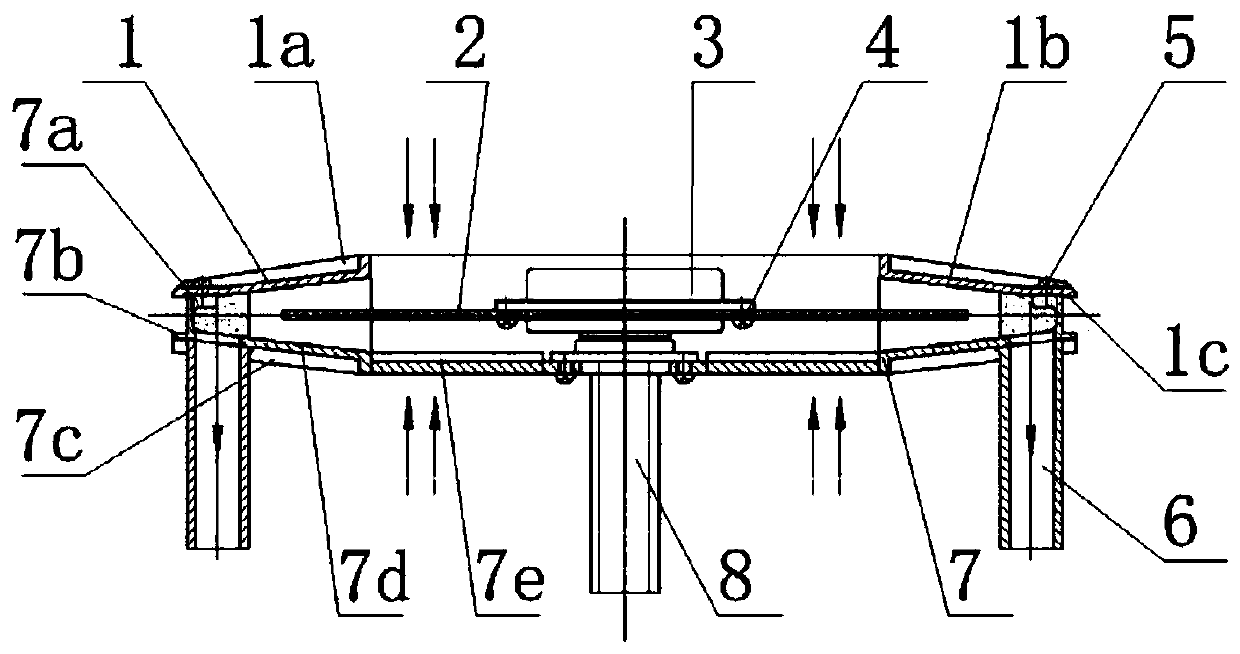

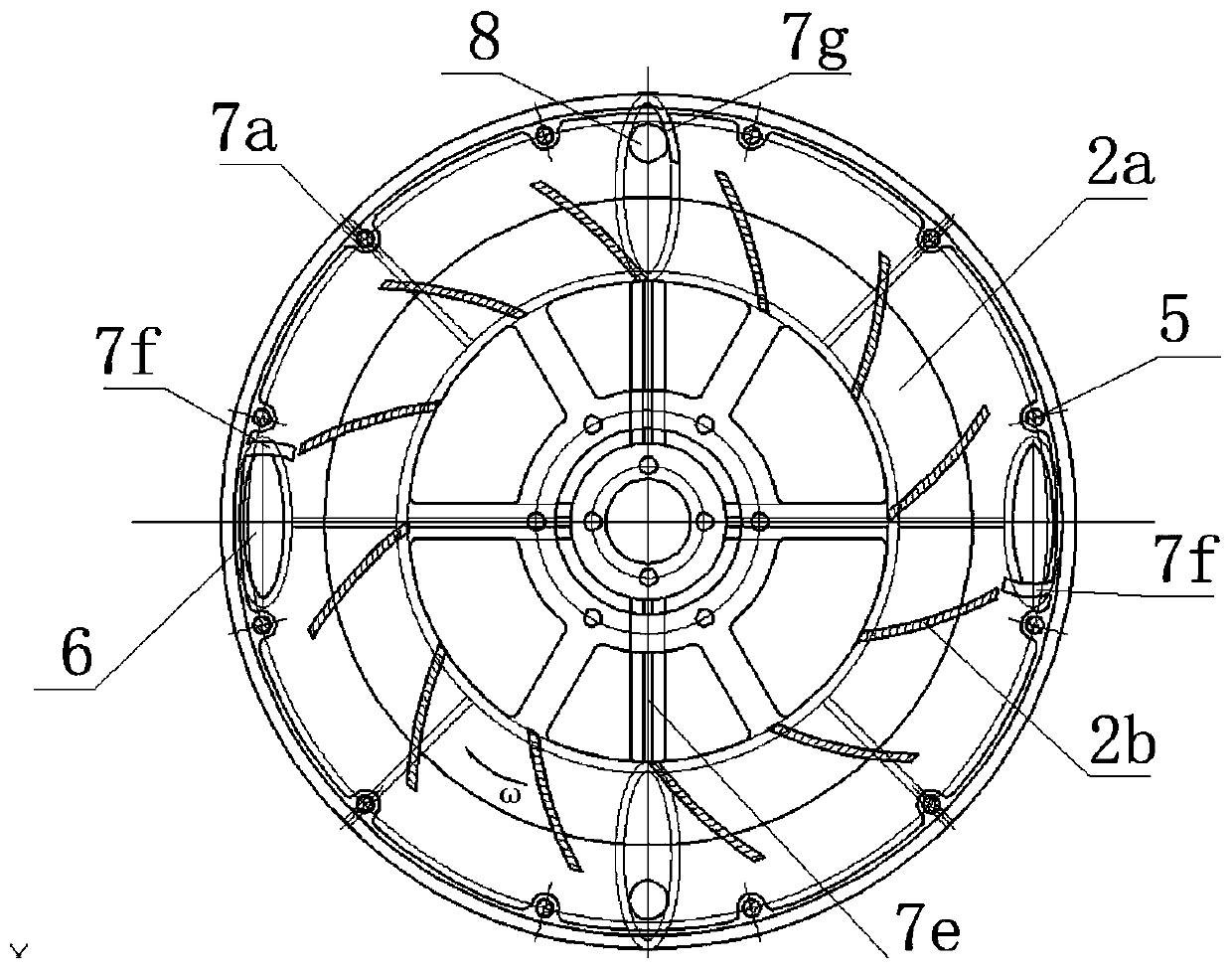

[0028] figure 1 Is the front view of the aircraft pressurization device. The frame of the power distributor 3 is fixedly connected with the flange at the center of the machine base 7 by bolts, the output disk of the power distributor 3 and the inner disk of the spoke disc of the impeller 2 are fixedly connected by the lower screw 4, and the upper cover 1 and the machine base 7 The inner protrusion 7a of the inner body is fixedly connected by the upper screw 5, and after assembly, the main body of the supercharging device in the shape of a flying saucer is formed. The upper rail surface 1c of the upper cover 1 and the lower rail surface 7b of the base 7 form a ring-shaped track, the lower cone surface 1b of the upper cover 1 and the upper cone surface 7d of the base 7 form the working chamber and the air collection chamber of the impeller, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com