Lifting camera

A camera and camera module technology, applied in the field of elevating cameras, can solve problems such as poor stability and reliability of elevating cameras, restricting the application and development of elevating cameras, and fracture of transmission parts or guides, and achieves process yield and mass production capacity. High, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

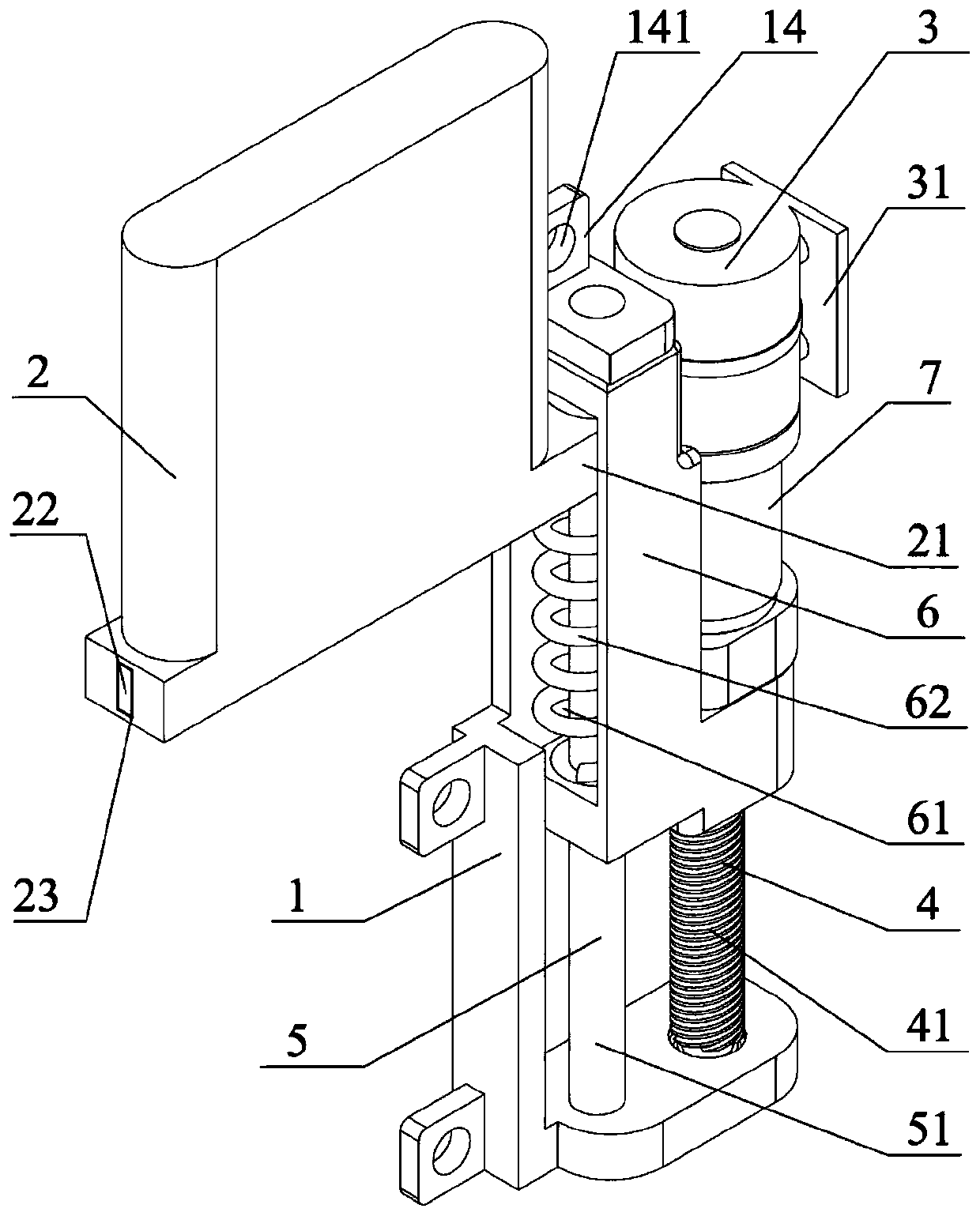

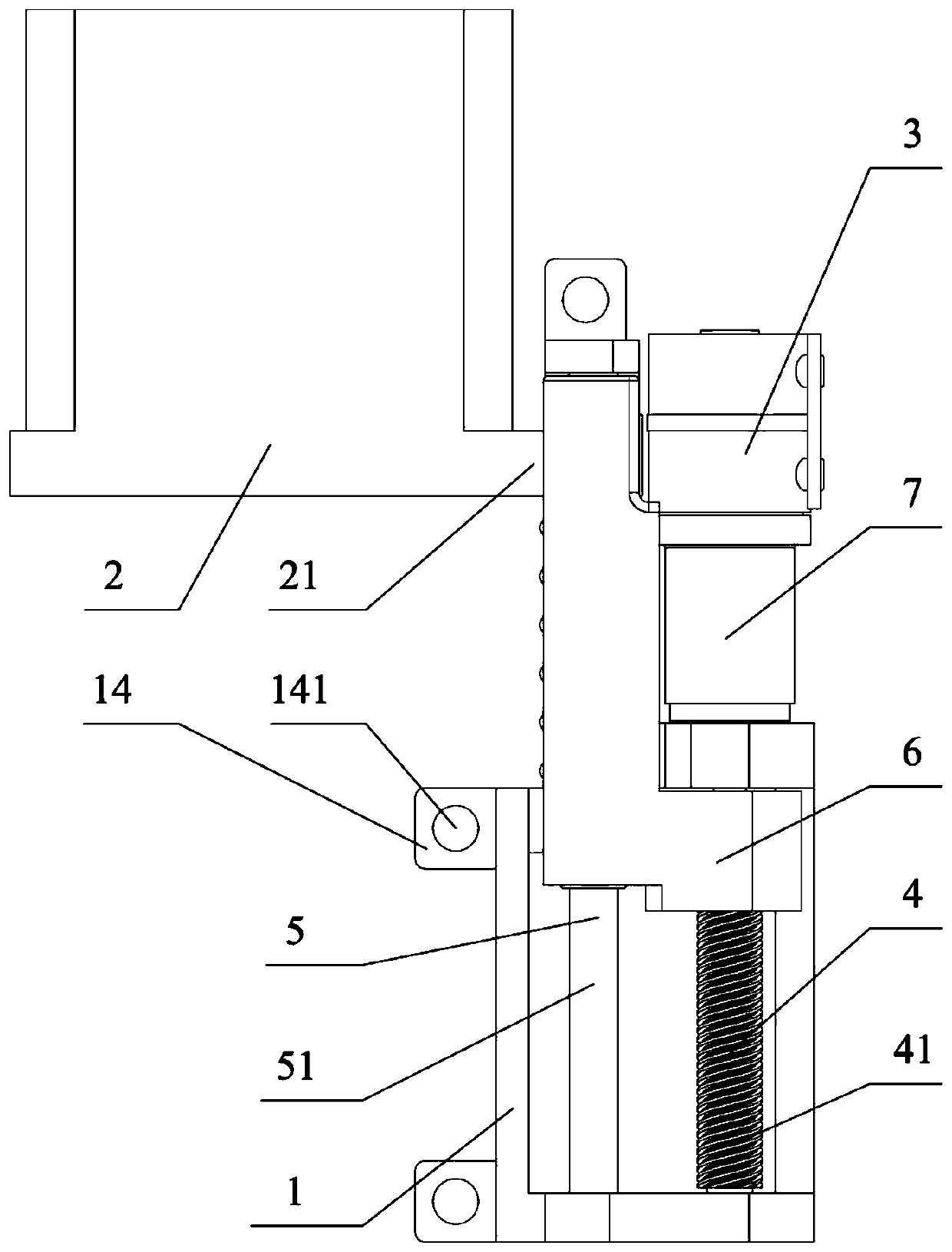

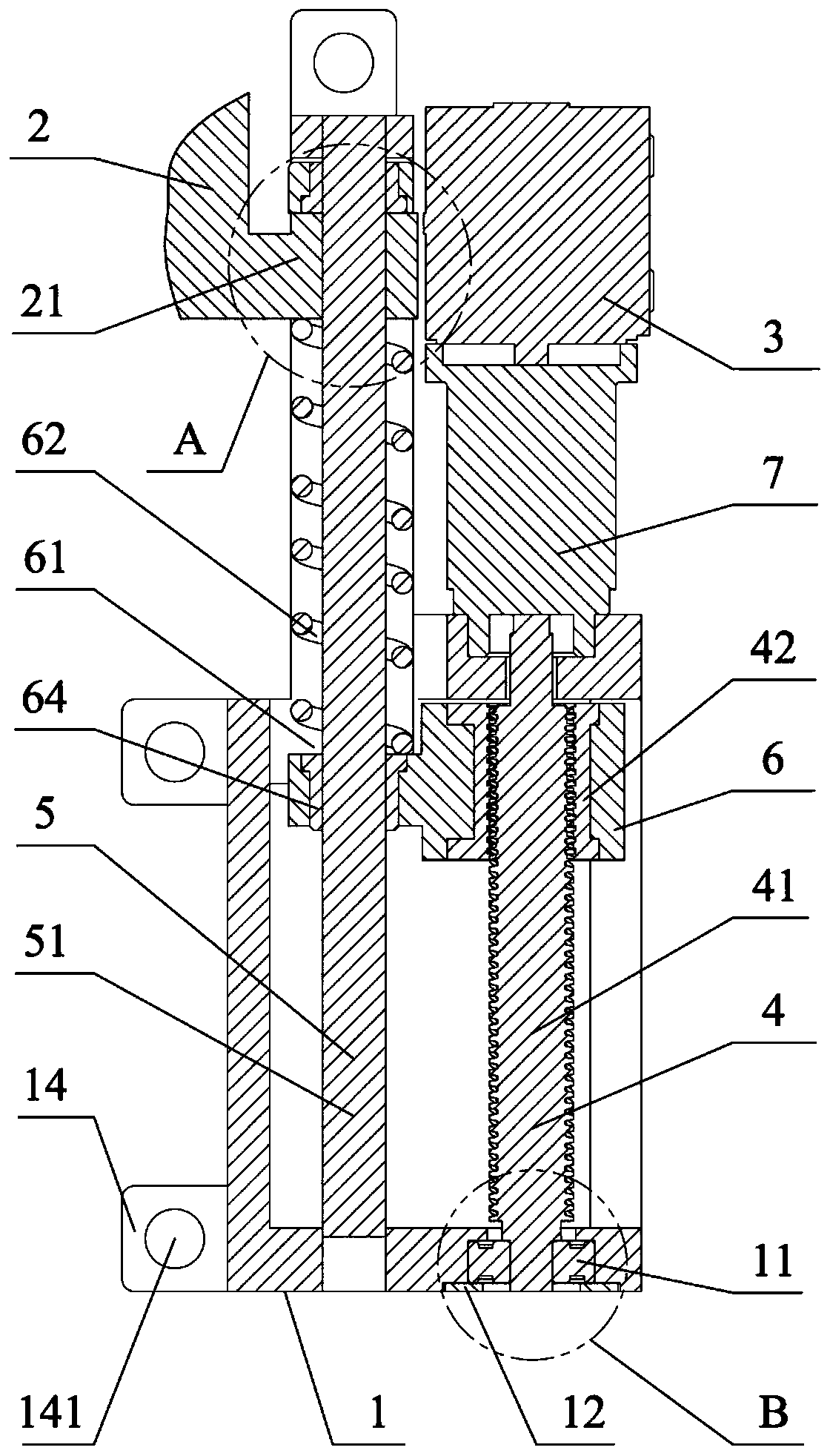

[0026] A lifting camera, such as Figure 1~5 As shown, it includes a support frame 1, a camera module 2 and a motor 3. The support frame 1 is provided with a transmission mechanism 4 and a guide mechanism 5. The transmission mechanism 4 is driven by the motor 3. The transmission mechanism 4 is provided with a slide table 6, and the slide The table 6 is slidably connected with the guide mechanism 5, and the camera module 2 is provided with an extension 21 connected with the slide table 6, and the slide table 6 is provided with a slideway 61 matched with the extension portion 21, and the length of the slideway 61 is The direction is consistent with the direction of the guide mechanism 5, the slideway 61 is provided with an elastic element 62 matched with the extension part 21, the elastic element 62 can keep the extension part 21 and the top of the slideway 61 to press fit, and the extension part 21 is in the The extruded elastic element 62 in the slideway 61 can slide along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com