Multi-test-surface building component fire resistance test device

A fire-resistant test and building component technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of energy waste, high energy consumption, and inaccurate temperature control accuracy, so as to reduce the loss of consumables, improve efficiency, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

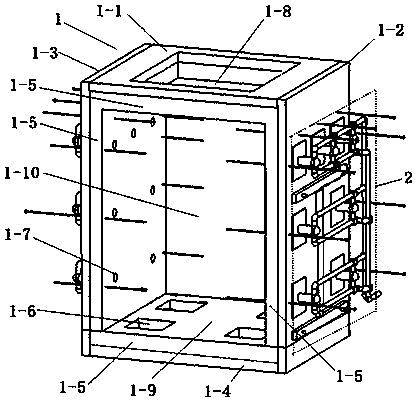

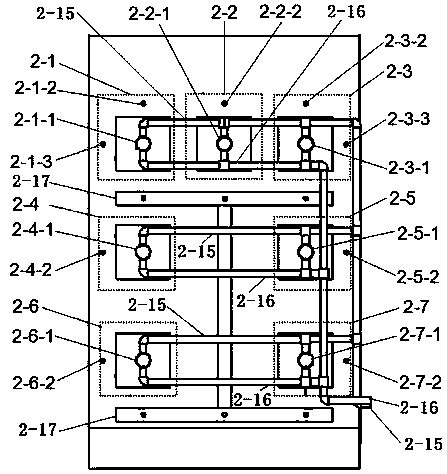

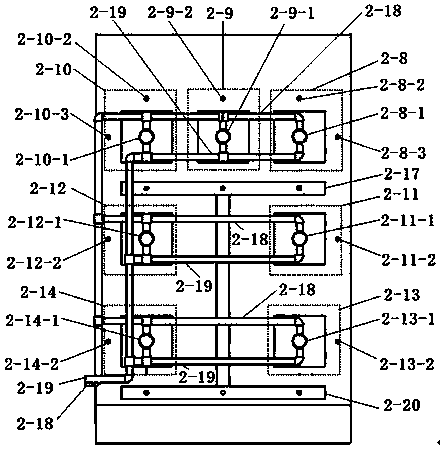

[0037] like Figure 1 to Figure 3 As shown, a multi-test surface building component fire resistance test device includes a main structure 1, a combustion and measurement and control system 2, the main structure 1 is composed of a furnace roof steel structure 1-1, a right side wall steel structure 1-2, a left side wall steel structure The structure 1-3 and the bottom steel structure 1-4 are fixed together by welding or screwing to form a frame structure. In the main structure 1, the furnace roof steel structure 1-1, the right side wall steel structure 1-2, and the left side wall On the surface of the steel structure 1-3 and the bottom steel structure 1-4, several refractory modules 1-5 are respectively provided to form a fire-resistant protection layer for equipment, and each refractory module 1-5 is fixed on the steel structure by an anchor, that is, the anchor One end is fixed by welding the steel wire and the steel structure, and the anchor is embedded in the refractory modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com