Circular ring side wall defect visual detection system

A visual inspection and defect technology, applied in the field of visual inspection, can solve the problems of complex and expensive algorithm steps and hardware facilities, affecting the operation efficiency and operation quality of visual inspection equipment, and being unfavorable to the use of general manufacturers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

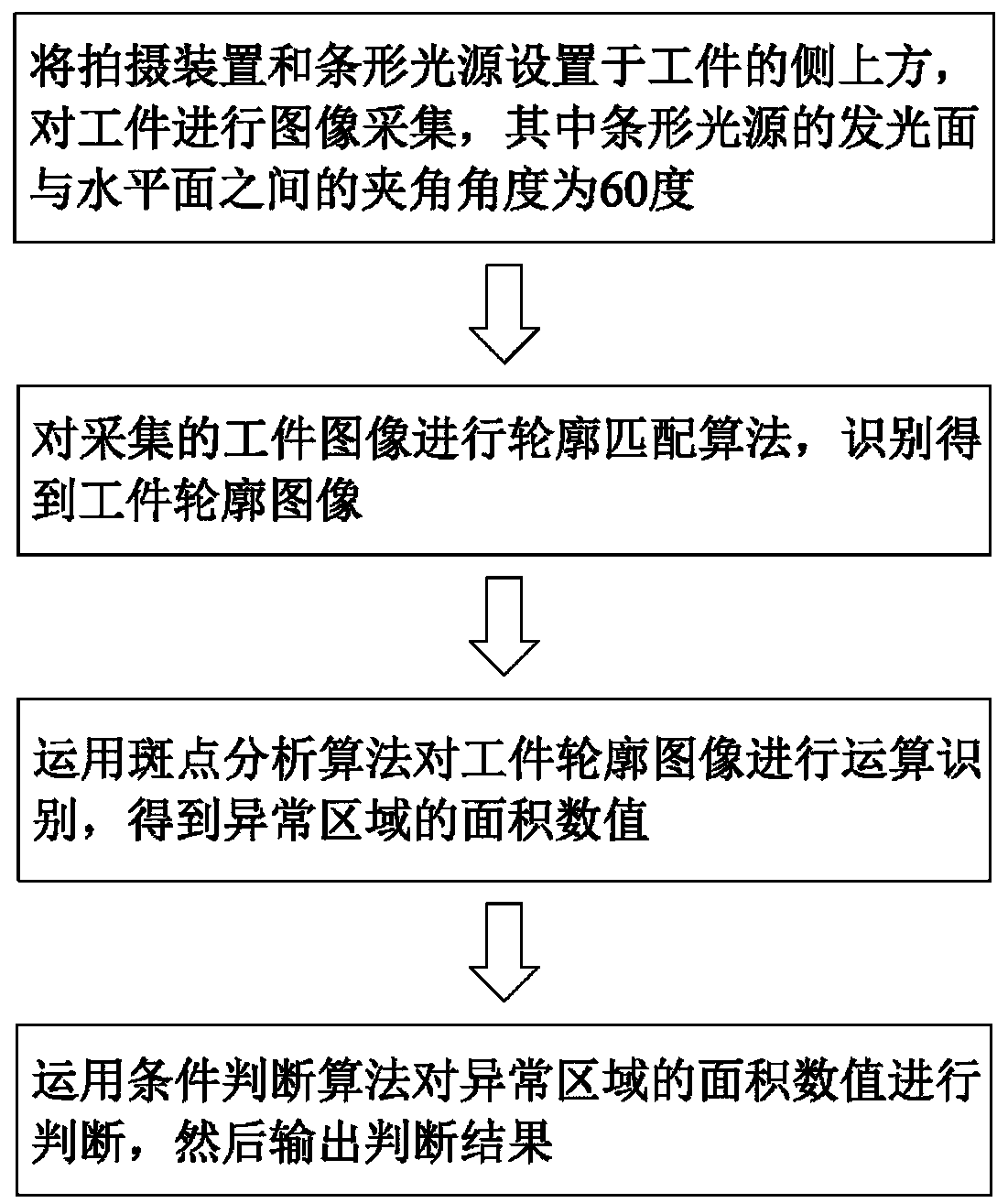

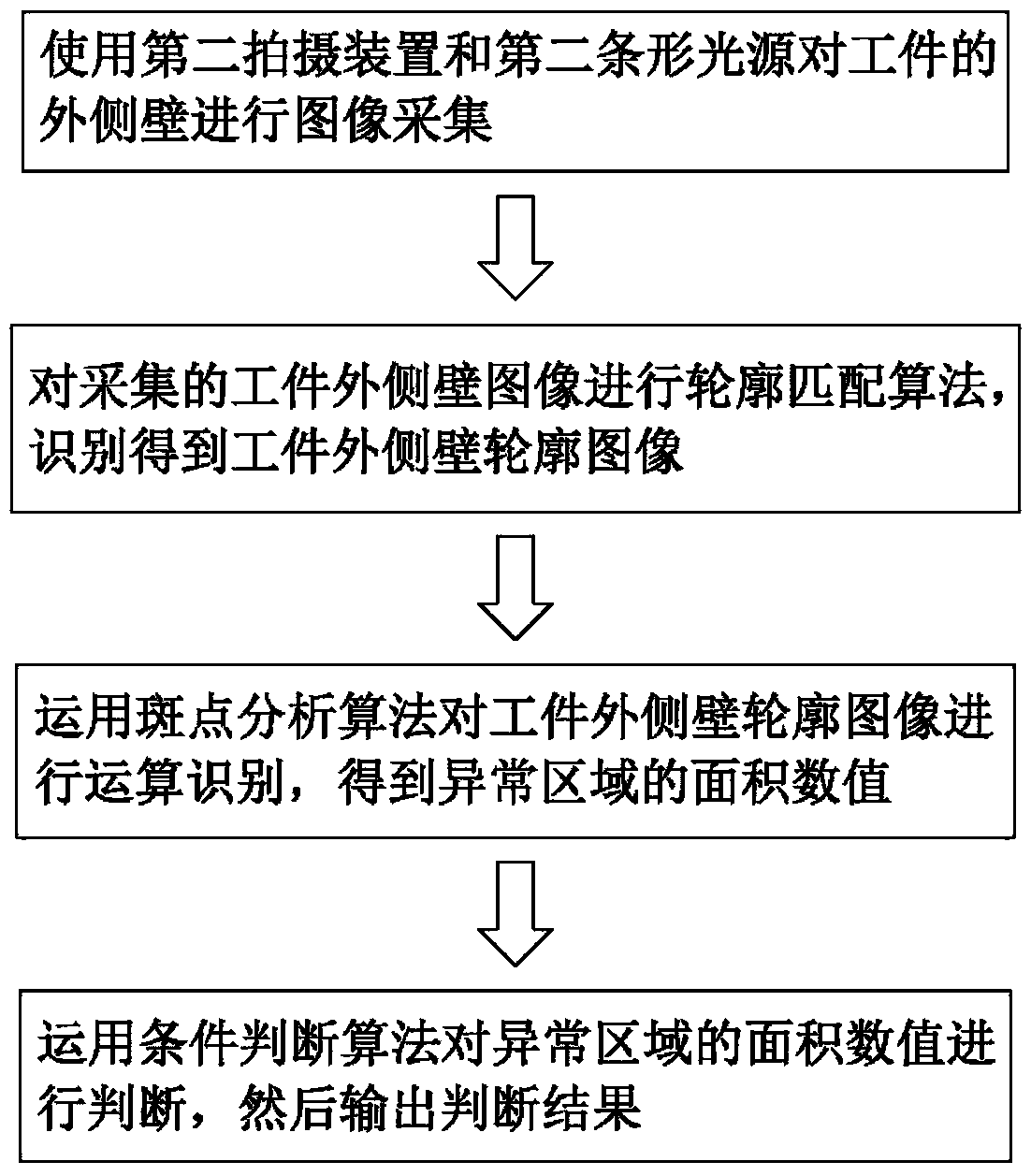

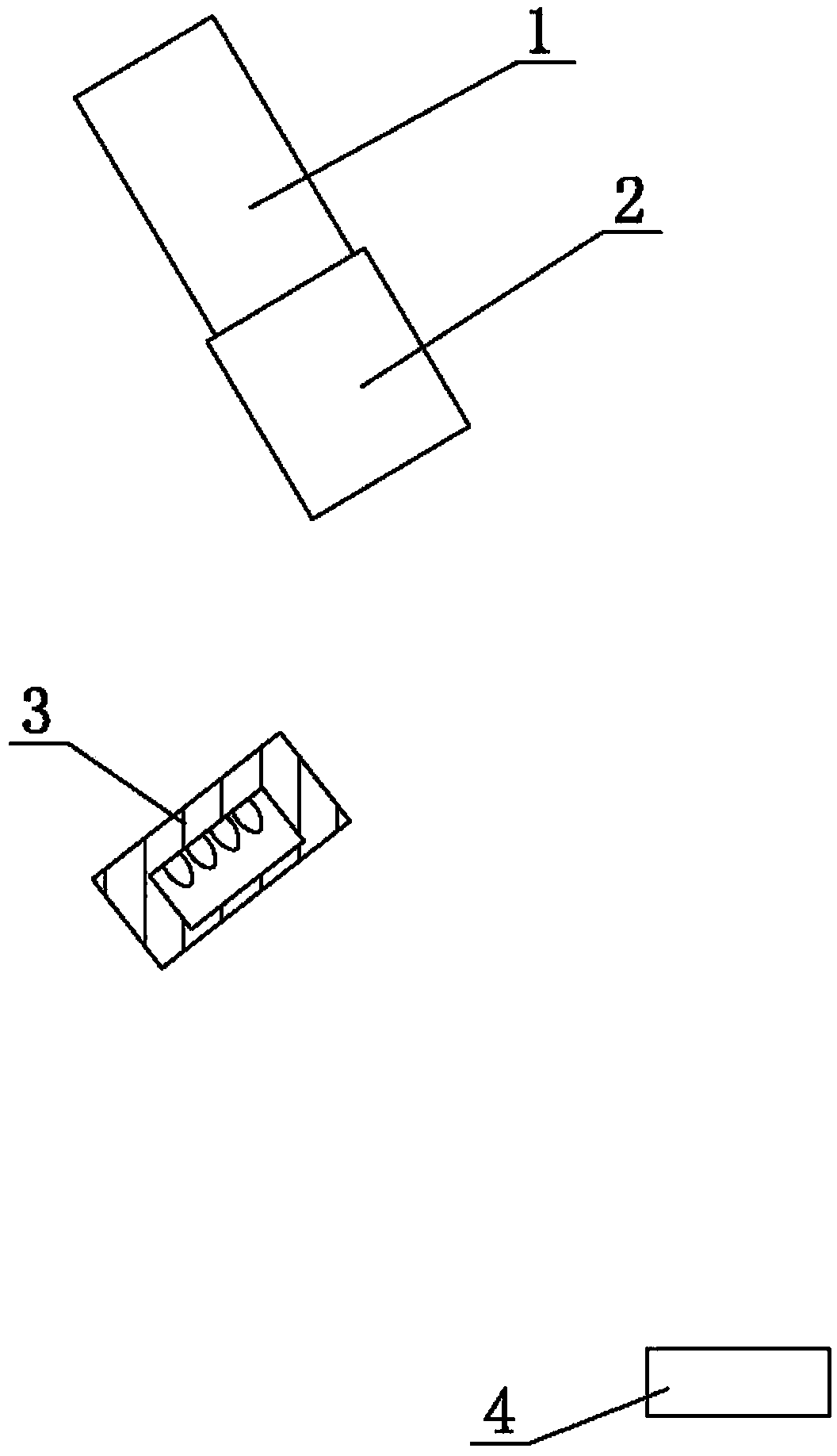

[0027] Such as figure 1 with image 3 As shown, a visual inspection system for ring side wall defects includes inspection station 1 and inspection station 2. The inspection steps of station 2 are as follows, step A: the first photographing device and the first bar light source 3 is arranged above the side of the workpiece 4 to collect images of the inner wall of the workpiece 4, wherein the angle between the light-emitting surface of the first bar-shaped light source 3 and the horizontal plane is 60 degrees, and the first bar-shaped light source 3 and the workpiece 4 The vertical distance between the upper sides is 35 millimeters, the first photographing device and the first strip light source 3 are located above the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com