Test system and method of high melting point phase saturation precipitation in high temperature melt

A high-temperature melt and testing system technology, which is applied in the direction of measuring devices, analytical materials, and thermal analysis of materials, can solve the problems of no testing system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with specific embodiments.

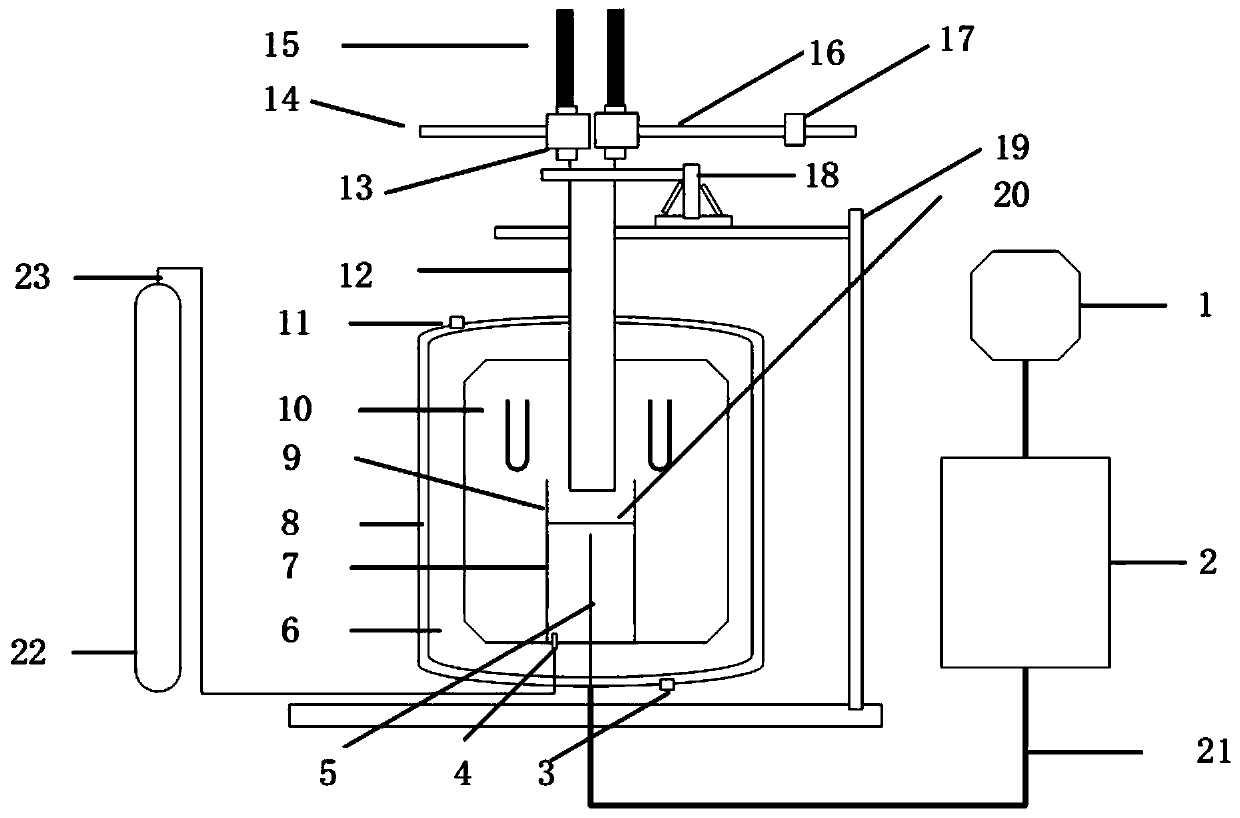

[0042] Such as figure 1 As shown, a high-melting-point phase saturation precipitation testing system in a high-temperature melt includes a vertical tube furnace, and the inside of the vertical tube furnace is a furnace cavity with a sealed cavity; the inside of the furnace wall of the vertical tube furnace is hollow Cooling chamber 8 is used to store cooling water; the bottom of the vertical tube furnace has a water inlet 3 communicated with the cooling chamber 8 for injecting cooling water into the cooling chamber 8; the upper part of the vertical tube furnace is opened There is a water outlet 11 communicated with the cooling chamber 8 for discharging cooling water from the cooling chamber 8; a pair of silicon-molybdenum rods 10 are arranged inside the furnace chamber for heating the furnace chamber; A corundum crucible 9 is placed at the bottom for containing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com