Optically Excited Infrared Thermography Defect Detection Method Based on Structured Sparse Decomposition

A technology of infrared thermal imaging and sparse decomposition, which is applied in the field of light-excited infrared thermal imaging defect detection based on structured sparse decomposition, can solve the problems of time-consuming and poor accuracy of variational Bayesian tensor decomposition method, and achieve suppression Effects of noise, detection rate improvement, and contrast enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

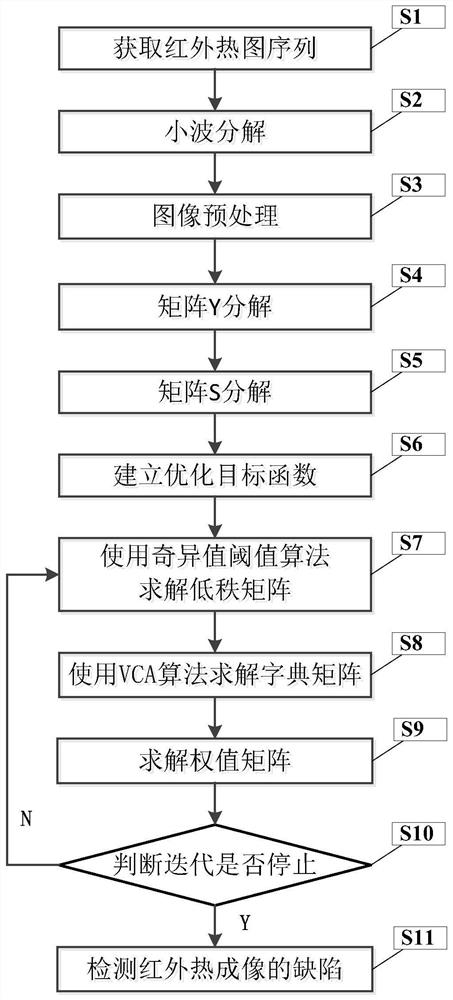

[0037] figure 1 It is a flow chart of the light-stimulated infrared thermal imaging defect detection method based on structured sparse decomposition of the present invention.

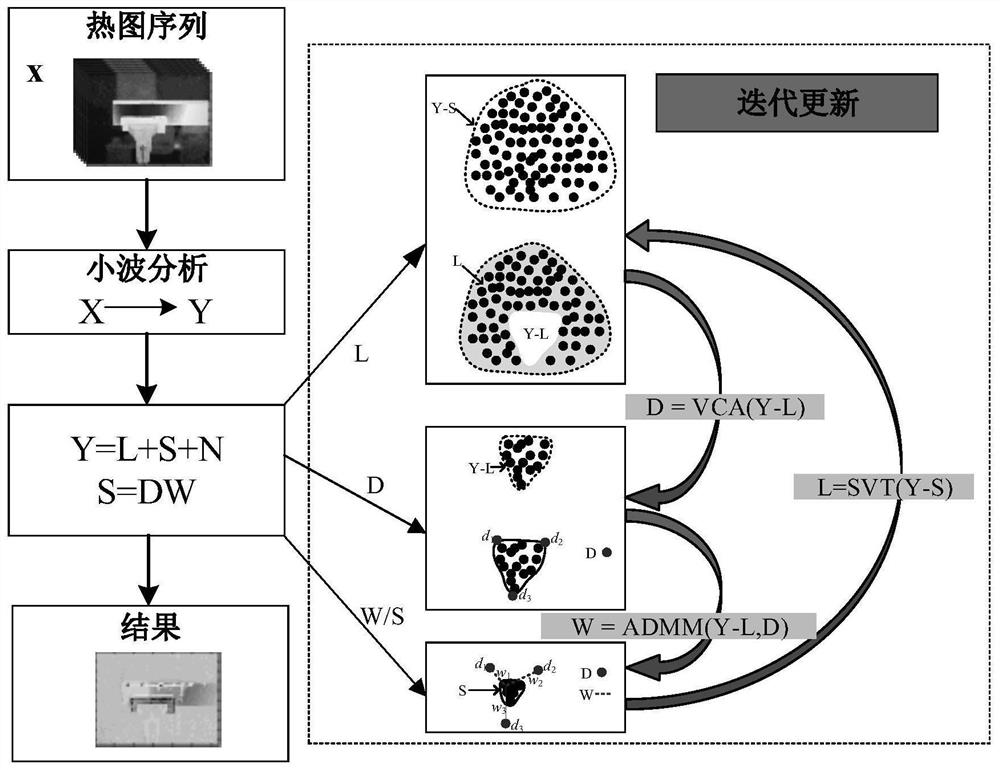

[0038] For the heat waves generated under the heating of the light source, when defects of different material properties are encountered inside the test piece, different heat densities will appear. By obtaining the surface temperature signal of the test piece, it will be displayed on the computer as a pseudo-color image. In the reflection mode (the thermal imager and the light source are on the same side), when there is a heat-insulating defect inside the specimen, the defect area will appear as a high-temperature area due to heat accumulation; when there is an endothermic defect inside the specimen, the defect area will appear as a It is a low-temperature area, and the distribution of defects is usually characterized by spatial sparseness. The location and number of defects can be determined by observi...

example

[0090] In order to evaluate the algorithm proposed by the present invention, five defect detection algorithms were selected for comparison, namely principal component analysis (PCA), independent component analysis (ICA), thermal signal reconstruction (TSR), pulse phase method (PPT) and variable Decibel Bayesian Tensor Factorization (EVBTF). In order to evaluate the defect detection effect and efficiency of each algorithm, three evaluation indicators are used, which are F-score, signal-to-noise ratio (SNR) and algorithm running time.

[0091] The definition of F-score is as follows:

[0092]

[0093] Among them, Precision is the precision rate, and Recall is the recall rate, which is defined as follows:

[0094]

[0095] Among them, TP represents the number of defects that are actually detected and detected, FP represents the number of defects that are actually not defective but are detected as defects, FN represents the number of defects that are actually not detected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com