Fuel cell system control method and device

A fuel cell system and fuel cell technology, applied in the direction of fuel cell control, fuel cells, fuel cell additives, etc., can solve problems such as poor real-time performance, complex structure, and influence on the stability of the output characteristics of the fuel cell system, and achieve Effects of eliminating control signal cross-correlation problems and solving inertia and delay problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

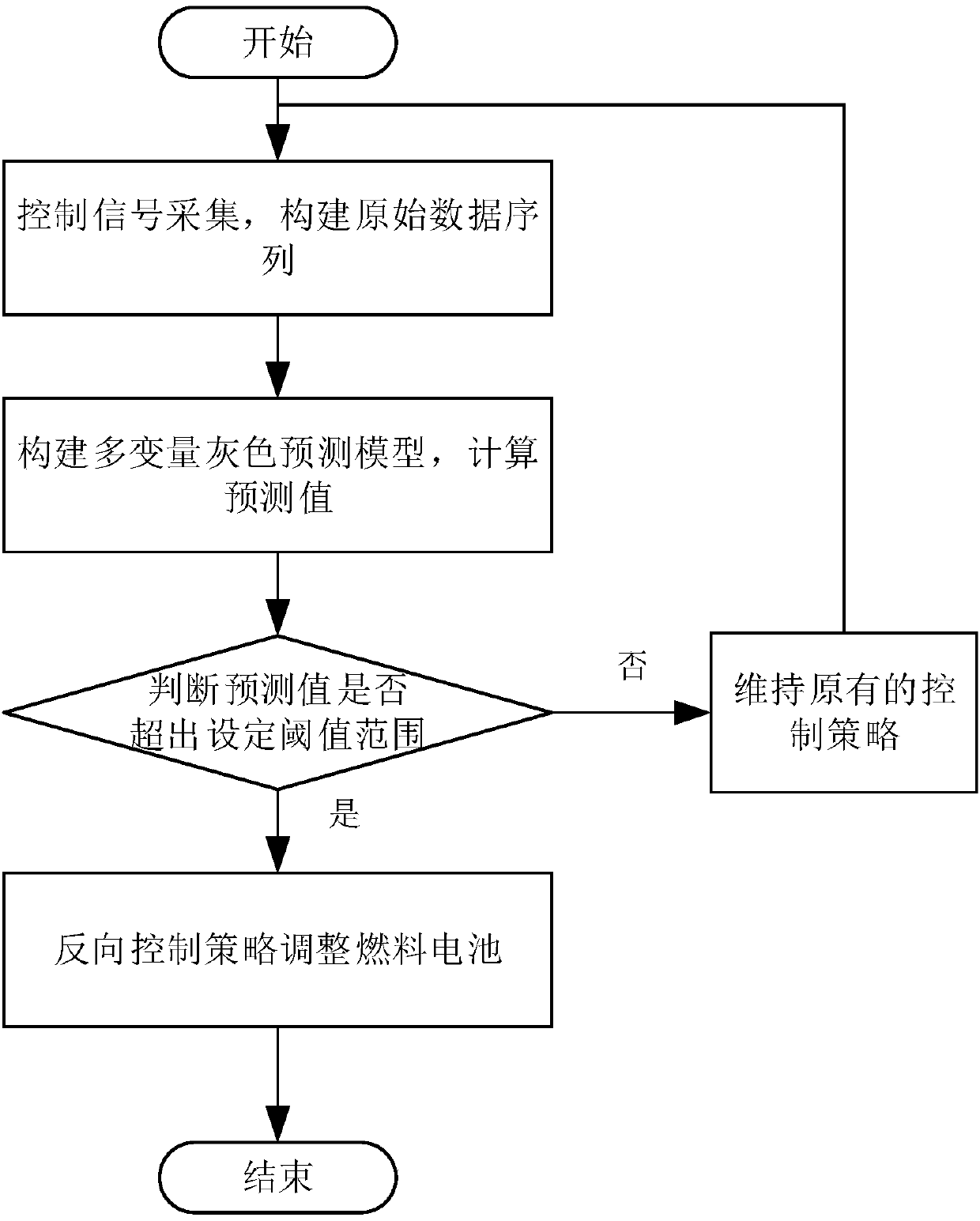

[0038] Embodiment 1 provides a fuel cell system control device, including a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the program, a fuel cell system control method is implemented. The control The method includes the following steps, such as figure 1 Shown:

[0039] Step S1: Collect information and construct the original data sequence.

[0040] Collect m data for each of the n control signal variables of the fuel cell, where the control signal variables include output voltage signal, output current signal, stack outlet pressure signal, stack outlet temperature signal, system hydrogen pressure signal, conductivity signal, air The compressor outputs at least two of the pressure signal, the air flow signal, and the hydrogen flow signal, but not limited to the above four kinds of control signals, and the original data sequence is

[0041]

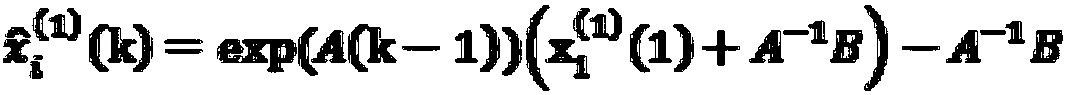

[0042] Wherein, n represents a control signal, and m repr...

Embodiment 2

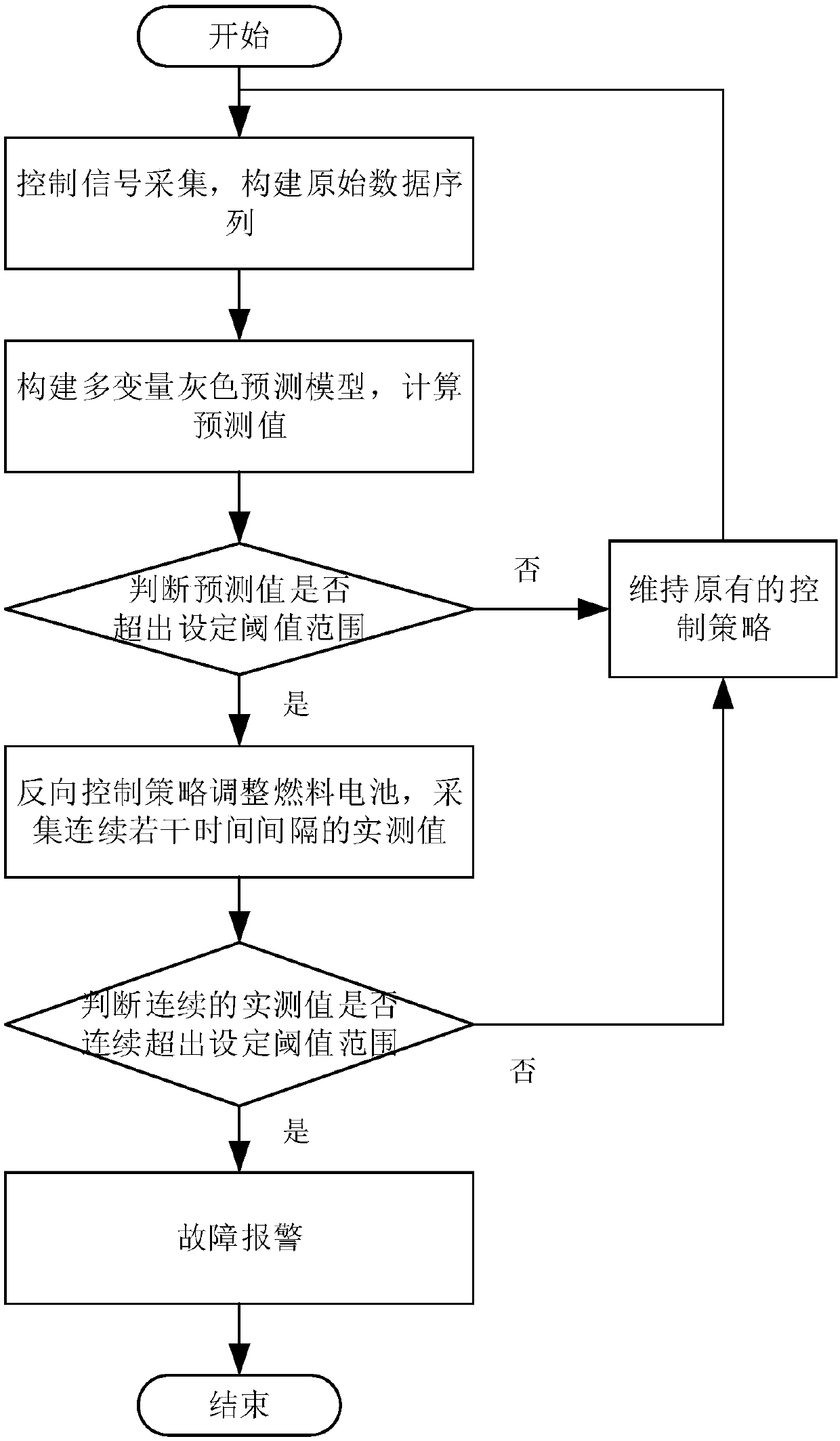

[0070] On the basis of Example 1, such as figure 2 As shown, the second embodiment also observes the measured value at the next time after the above step S3, and compares the measured value at the next time with the set threshold range.

[0071] After the fuel cell is controlled by the reverse control strategy, the measured value at the next moment is obtained, and it is judged whether the measured value at the next moment exceeds the set threshold range. If so, the control sends out a fault alarm to remind the user to take corresponding measures.

[0072] In addition, because the above-mentioned fault alarm is only controlled by the determination of the actual measured value and the set threshold range once, the control is not precise enough, and false alarms may occur.

[0073] Therefore, this embodiment 2 also proposes that after the reverse adjustment of the control strategy of the fuel cell in step S3 of the above embodiment 1, a plurality of measured values of several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com