Processing method for lithium ion cell and processing device for composite battery electrode sheet

A technology for battery pole pieces and composite batteries, which is applied in the processing of lithium-ion batteries and processing devices for composite battery pole pieces. It can solve problems such as low production efficiency and easy generation of burrs, and achieve the goal of reducing equipment investment and reducing burrs. Probability, the effect of simplifying production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

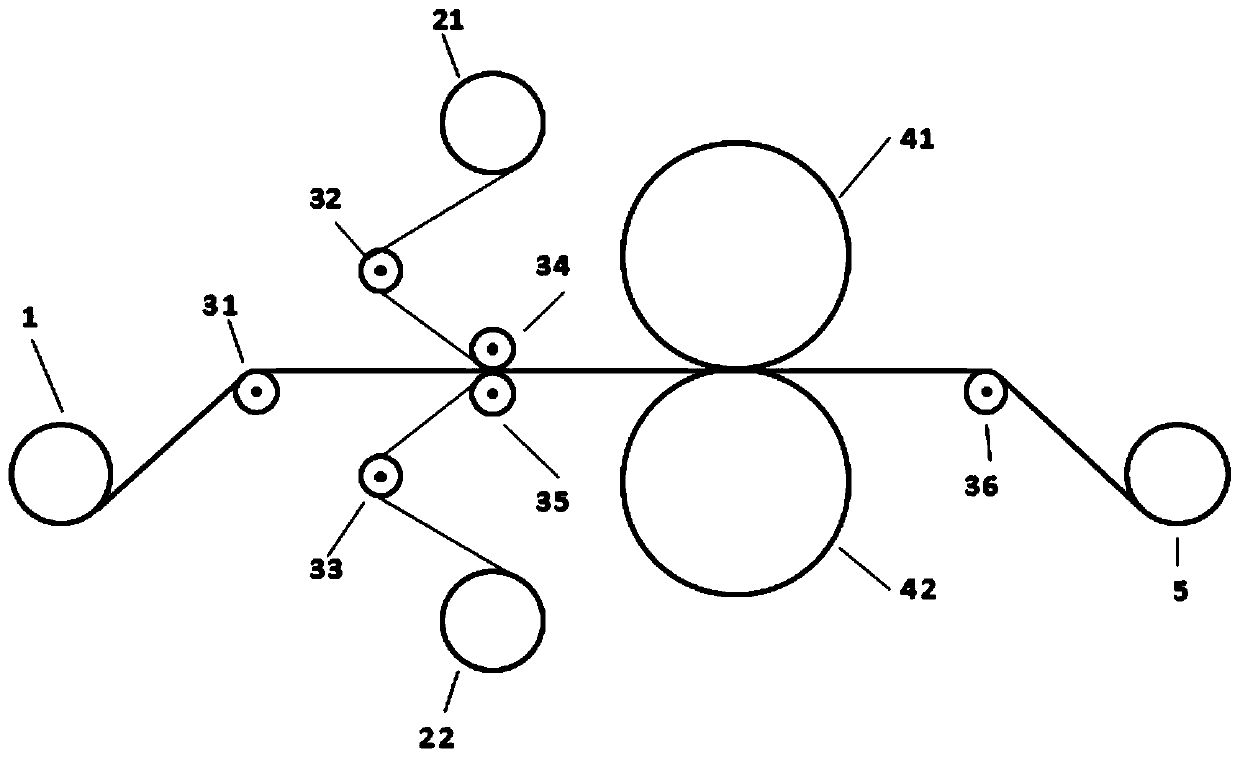

[0042] see Figure 1-3 , when this embodiment is in use, place the battery positive roll on the pole piece unwinding roller 1, and place the two rolls of battery separator on the first separator unwinding roller 21 and the second separator unwinding roller 22 respectively , in this embodiment, the diaphragm adopts a glue-coated diaphragm, and the side of the diaphragm close to the pole piece is coated with a glue layer. The thickness of the glue layer is 0.5 μm, and the glue layer is oil-based PVDF. Roller 1 pulls out and walks around the first guide roller 31, then passes through the fourth guide roller 34 and the fifth guide roller 35, and then the first diaphragm and the second diaphragm are unwound from the first diaphragm respectively. 21 and the second diaphragm unwinding roller 22 are pulled out and passed around the second guide roller 32 and the third guide roller 33 respectively, and then the first diaphragm and the second diaphragm are attached to the upper and lowe...

Embodiment 2

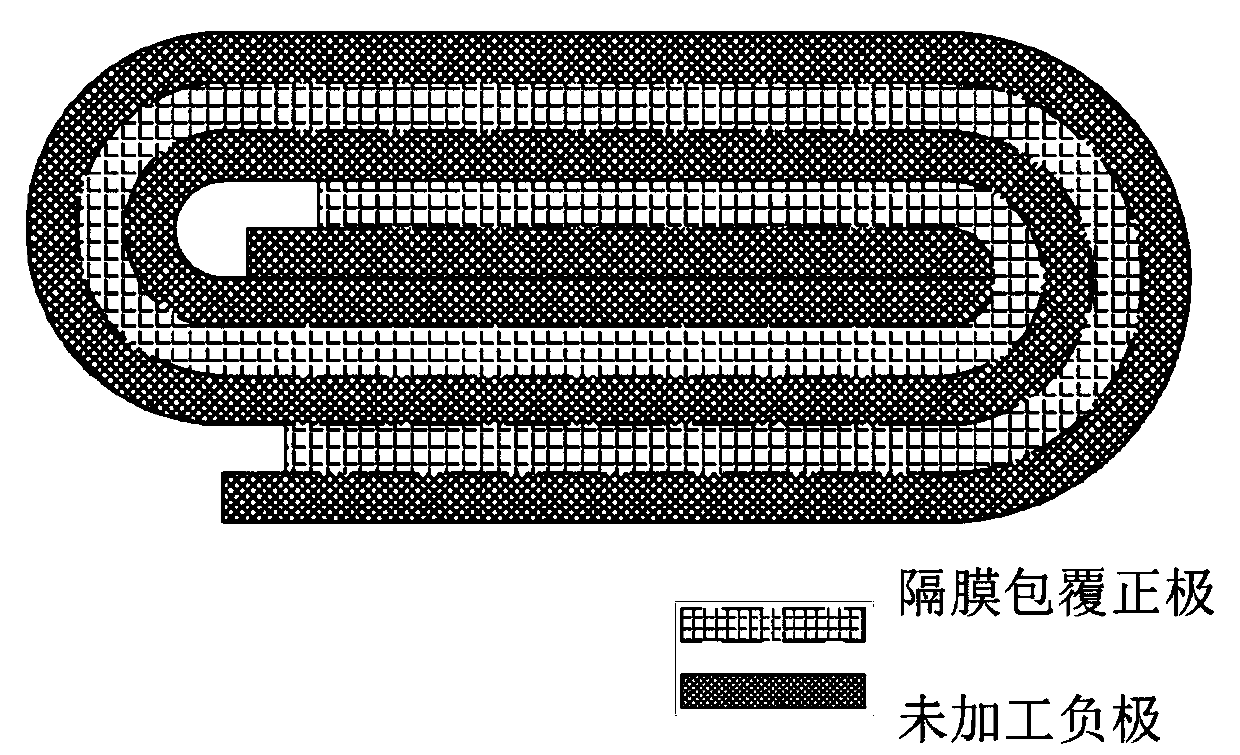

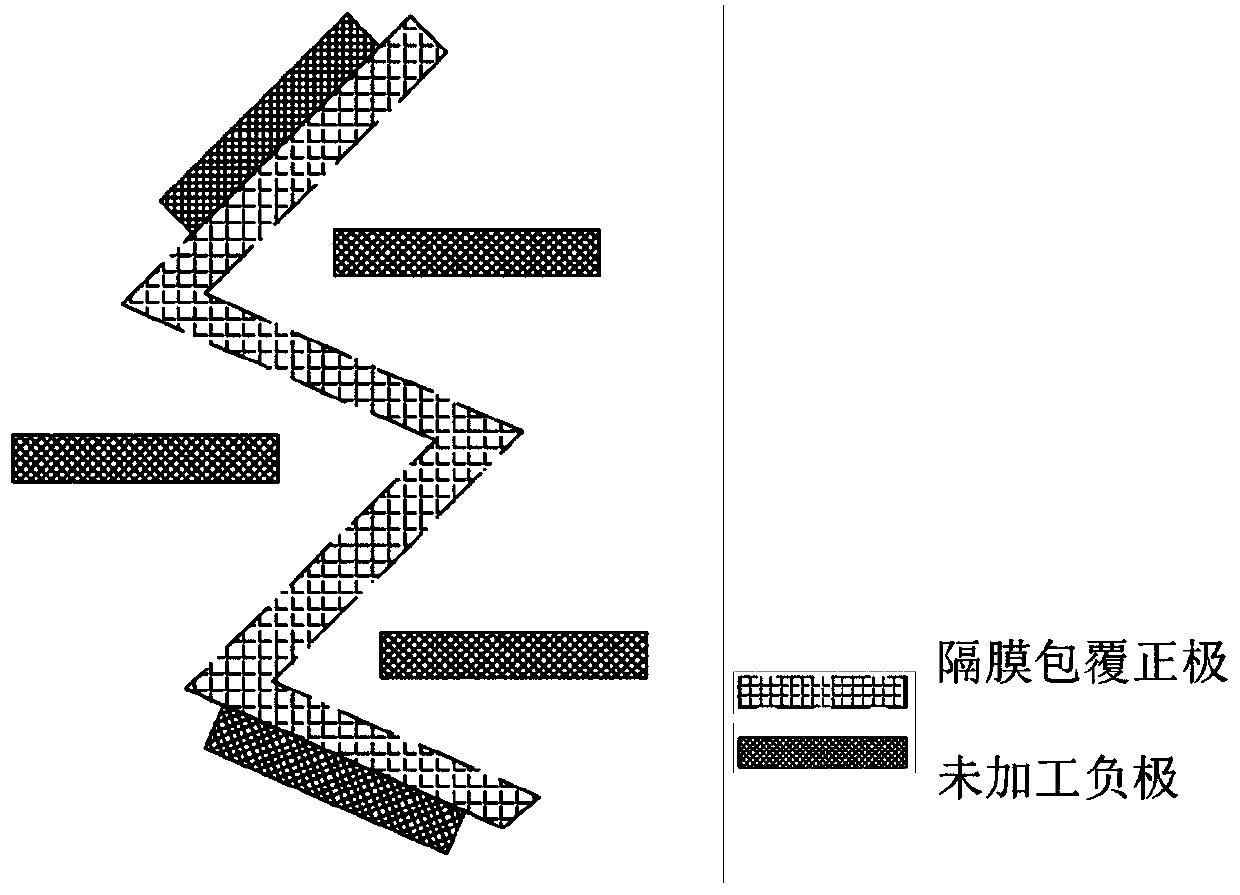

[0044] see figure 1 , Figure 4-5 In this embodiment, the negative pole piece of the battery is placed on the pole piece unwinding roller 1, the separator is glued with water-based AFL with a thickness of 2 μm, and the temperature of the first pressing roller 41 and the second pressing roller 42 is 100°C , the pressure of the first pressure roller 41 and the second pressure roller 42 is 3000Kg, and the rest are the same as in Example 1, and then the negative electrode sheet coated by the separator on both sides can be produced, such as Figure 4 , Figure 5 As shown, the application of the negative electrode sheet covered by the separator processed in this embodiment in the production of wound electric cores and laminated electric cores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com