Device for dismounting high-voltage line T-shaped clamp in hot-line work

A technology for live work and high-voltage lines, applied to overhead lines/cable equipment, etc., can solve the problems of bolt tightening torque failing to meet national standards, difficult for operators to perform actions, and difficult to replace bolts in time, so as to improve the reliability of power supply. , The effect of improving work efficiency and reducing work risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

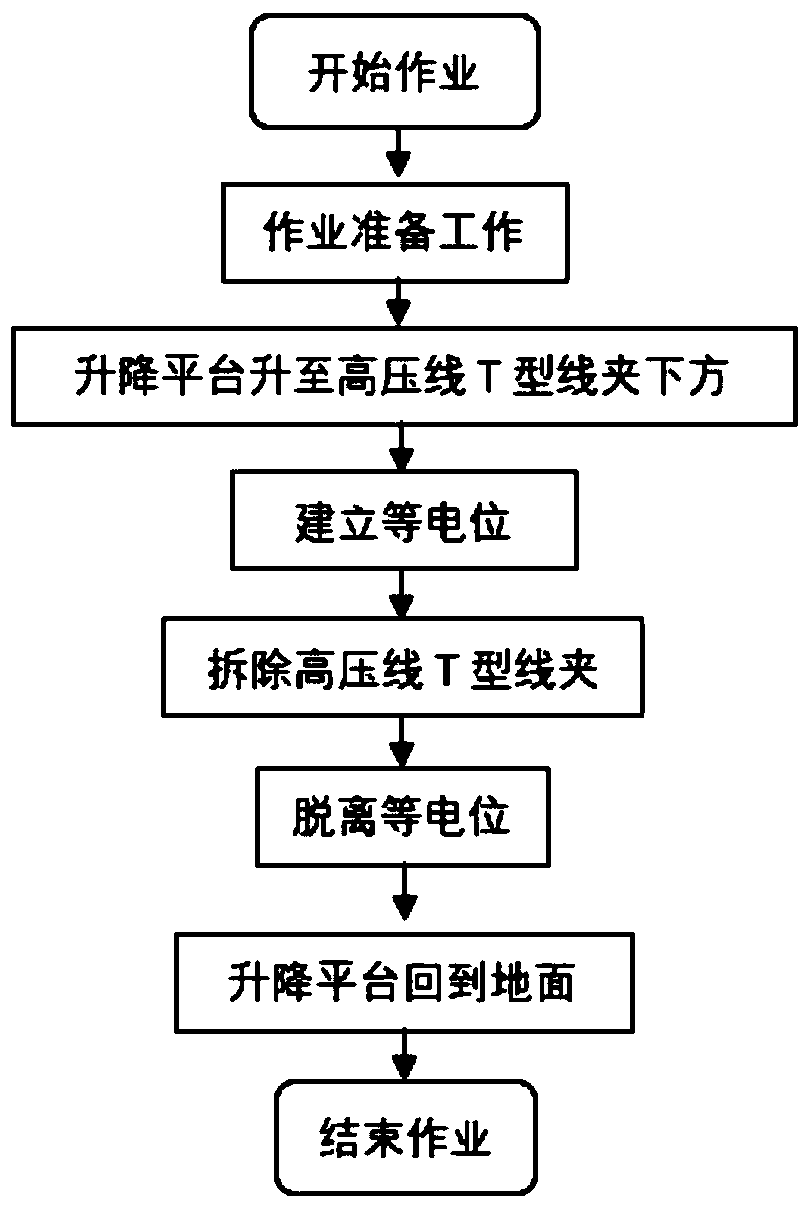

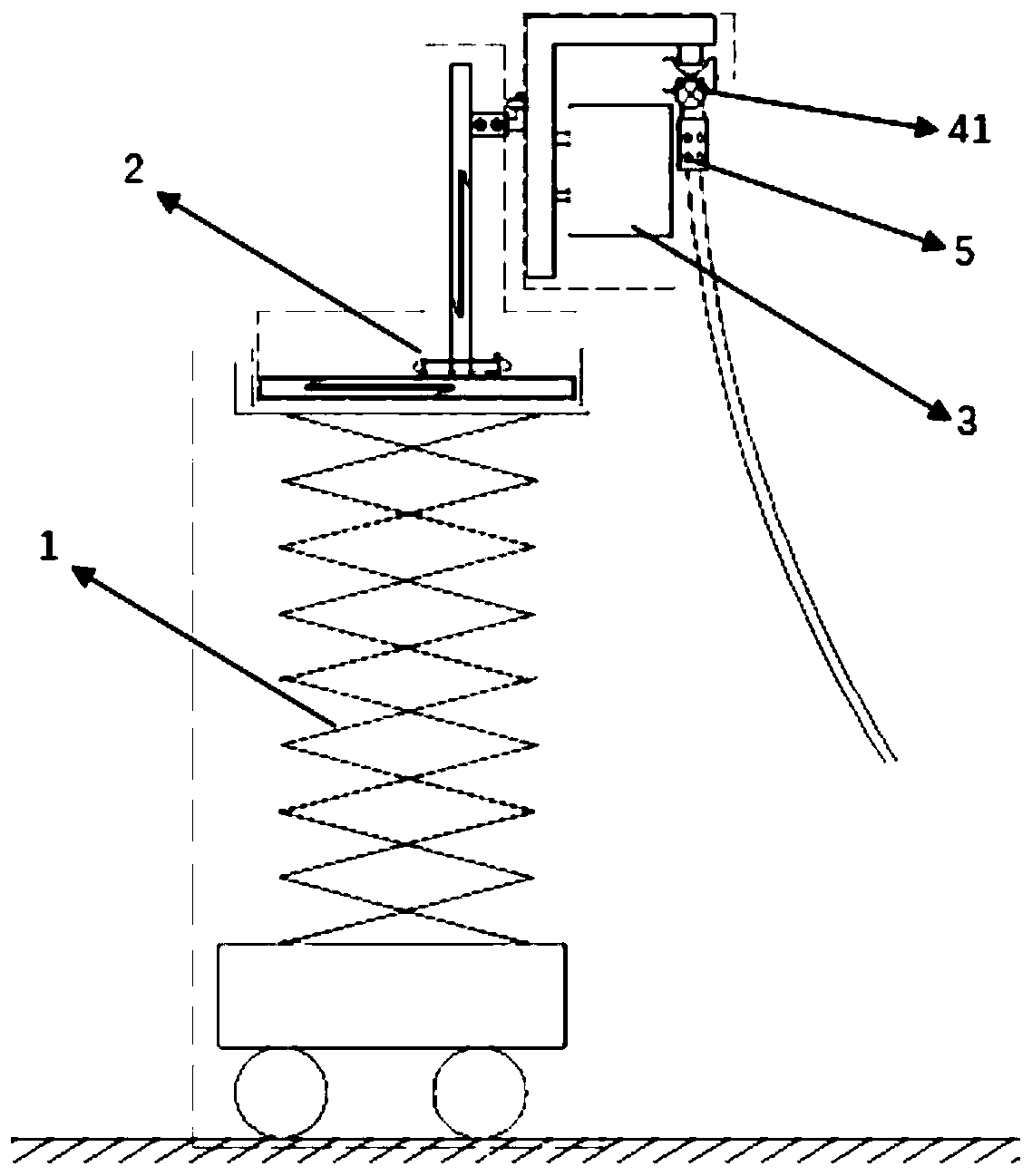

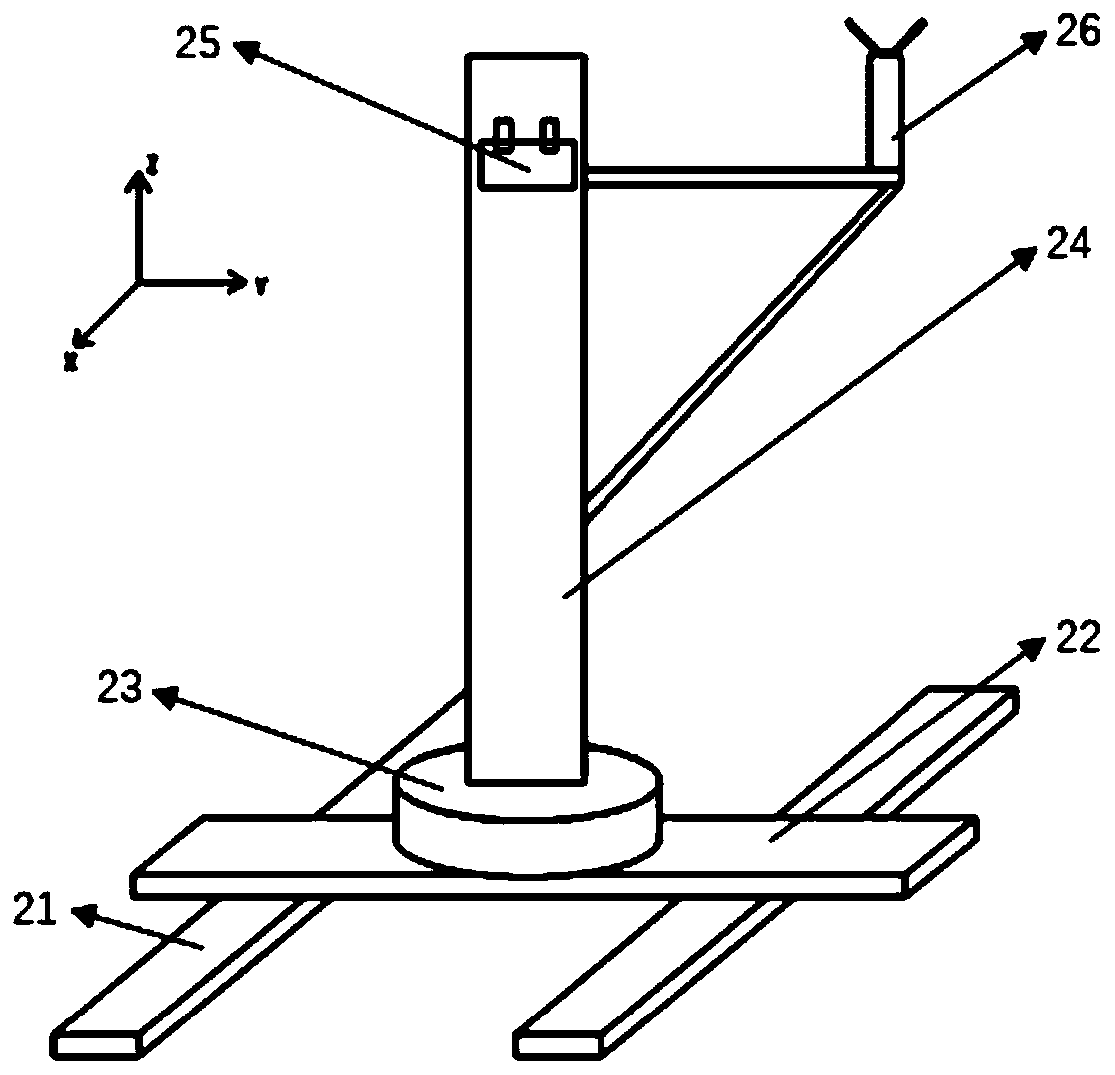

[0026] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings. The interpretation of each label in the figure is: lifting platform 1, four-axis platform 2, first X-direction guide rail mechanism 21, first Y-direction guide rail mechanism 22, first rotary Mechanism 23, first Z-direction rail mechanism 24, hook 25, equipotential mechanism 26, cross bar 261, inclined bar 262, pneumatic push rod 263, gripper jaw 264, bottom plate 211, linear guide rail 212, mounting plate 213, screw rod 214 , motor and reducer 215, end effector 3, integral frame 31, damping wheel 32, second X-direction rail mechanism 33, second Y-direction rail mechanism 34, second Z-direction rail mechanism 35, nut cutter 36 , the second rotary mechanism 37, the sub-line connection plate gripper 38, the high-voltage bus 41, the branch line 42, the high-voltage line T-shaped clamp 5, the bus connection plate 51, and the sub-line connection plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com