Vehicle sealing strip skeleton and machining process thereof

A processing technology and a technology for sealing strips, applied in the field of vehicle sealing strip skeleton and its processing technology, can solve the problems of not meeting the new requirements of energy saving, environmental protection and light weight of passenger cars, low utilization rate of raw materials, insufficient production efficiency, etc. Achieve the effect of easy bending, high strength and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

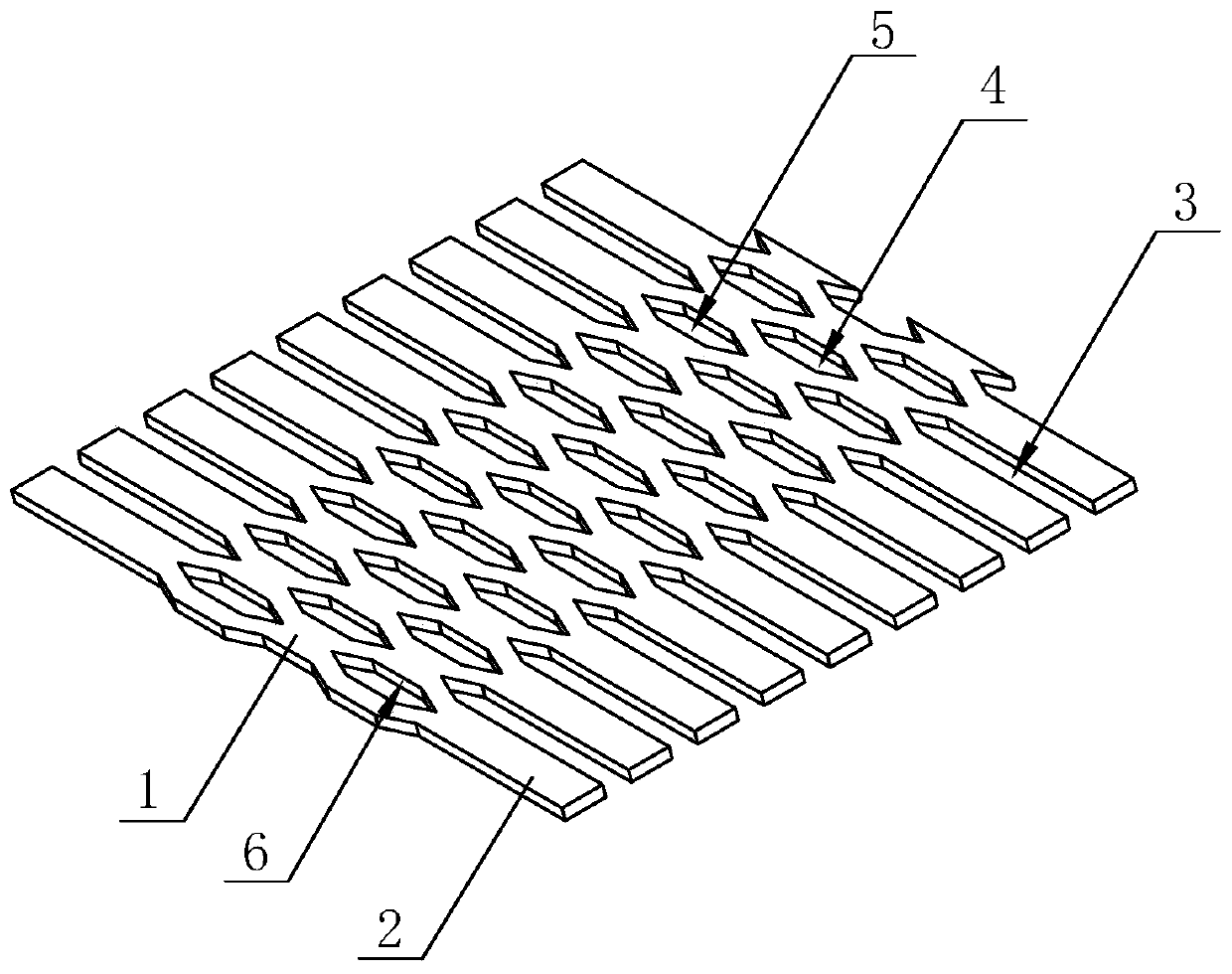

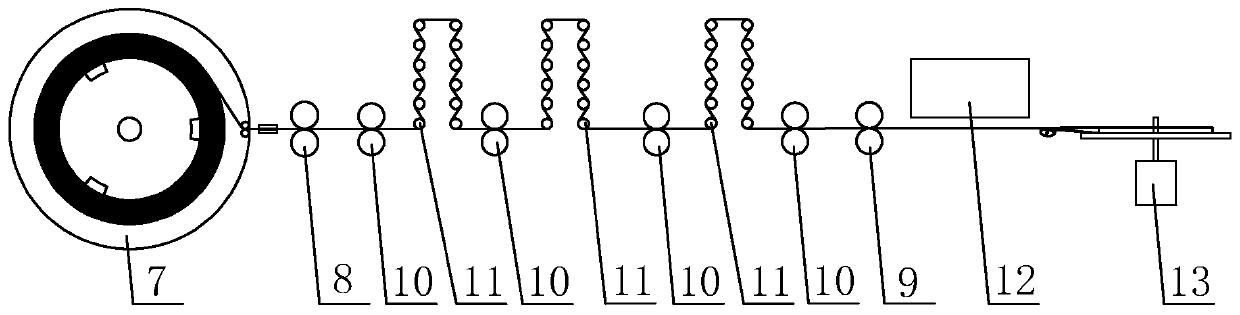

[0042] A kind of vehicle sealing strip skeleton, such as figure 1 As shown, it includes a stretching belt 1, and a plurality of bone pieces 2 are fixed in a symmetrical array on both sides of the stretching belt 1. The bone pieces 2 and the stretching belt 1 are integrally arranged and have the same thickness. The surface of the bone pieces 2 is rectangular, and the adjacent bone pieces 2 is provided with a gap 3, the stretching belt 1 is provided with a plurality of middle holes 4 at equal intervals along the central axis direction, and the stretching belt 1 is provided with side holes 5 on both sides between adjacent middle holes 4, and the side holes 5 has the same shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com