Method of manufacturing yarn containing jade powder with far infrared ray activity and bedding product using yarn produced thereby

A technology of jade powder and raw silk, which is applied in the field of bedding, can solve the problems of difficulty in uniform coating, loss of far-infrared function, difficulty in confirming the preparation process and the durability of the far-infrared effect raw silk, and achieve far-infrared radiation performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

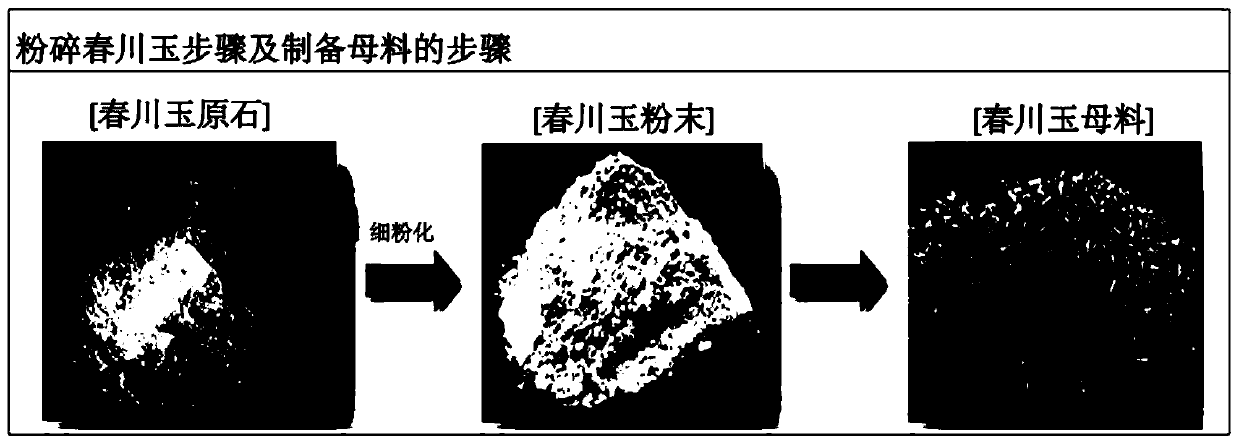

[0026] Preparation of jade powder

[0027] Although nephrite, jadeite, and serpentine can all be used, the jade used in the embodiment of the present invention is Chunchuan jade in nephrite. By pulverizing the raw Chunchuan jade stone, a uniform fine powder of 0.5 to 1 μm is achieved. The size of jade powder is determined by the thickness of the raw silk. If the raw silk is thicker, you can use a larger powder. However, considering the strength of the final drawn yarn, far-infrared radiation rate, spinnability, etc., an appropriate particle size is specified. Very important. The present invention prepares jade-containing stretched yarns with a denier of 40-85 and a filament count of 36-204 through final stretching, and it is confirmed that the particle size of the jade powder cannot exceed 1 μm.

[0028] Powder size and spinnability

[0029] (1) The size of jade powder is 500~700nm

[0030] It is easy to spin because the powder is well dispersed in the original yarn, which...

Embodiment

[0050] Preparation of masterbatch

[0051] By mixing 20% by weight of jade powder, which is completely dried and dehydrated under vacuum, to 80% by weight of polyester chips and put into the initial interval, intermediate interval, and final interval to maintain the temperature of 250°C, 260°C, and 270°C respectively screw extrusion machine. Resin that becomes liquid in a high temperature state is drawn out through a nozzle, cooled, and continuously cut into a predetermined length of 2×3 mm to prepare a masterbatch.

[0052] melt spinning

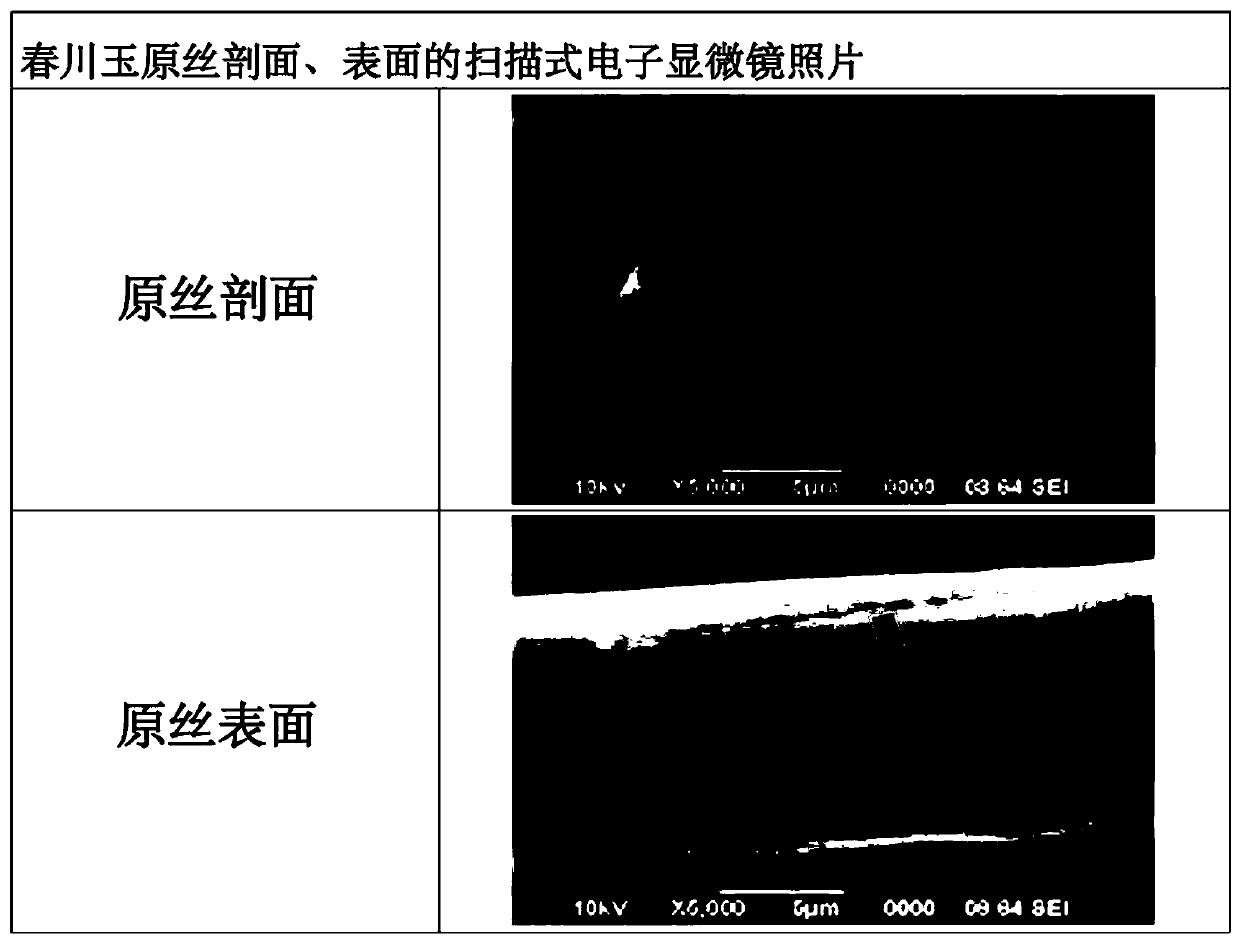

[0053] A 75-denier, 36-filament drawn yarn (DTY) was prepared by mixing 7% by weight of the masterbatch prepared and dried in the above-mentioned steps with 93% by weight of the polyester raw material and performing melt spinning, false twisting and drawing. As a result of observing the surface and section of the actual raw silk through a microscope, it was confirmed that Chunchuan jade powder was located on the surface and inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com