Fiber and preparation method thereof

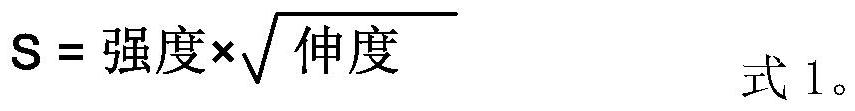

A fiber and polyimide fiber technology, applied in the field of fibers, can solve the problems of poor dimensional stability, poor spinning performance and mechanical properties of polyimide fibers, and achieve good mechanical properties, superior spinning performance, and difficult fiber. shrinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Put 4100g of γ-butyrolactone into a four-neck flask, raise the temperature to 70°C, and purge with nitrogen gas, the nitrogen flow rate is 3ml / min; then 453.5g of 2,3,3',4'-biphenyl Tetraformic dianhydride (Junkai Chemical) and 173.5g of p-phenylenediamine (Zhixin Chemical) were added to the flask respectively, and after stirring for 1.5h, 7.2g of polysiloxane diethyl ester (weight average molecular weight about 300, quasi-biotechnology) into the reaction system, and then stirred for 3h; then 301.4g of diethyl carbonate (TCI) was put into the reaction system, and stirred for 60min to obtain a fiber-forming polymer solution; The fiber polymer solution has a solid content of 18.4% and a weight average molecular weight of 815,300.

[0053] Then, the fiber-forming solution is spun by the common dry-wet spinning method, the spinning temperature is 130°C, after passing through the coagulation bath, then through the water washing tank, and dried by hot air at 95°C at a draft r...

Embodiment 2

[0055] Put 4100g of γ-butyrolactone into a four-neck flask, raise the temperature to 70°C, and purge with nitrogen gas at a flow rate of 3ml / min; then 529.2g of 2,3,3',4'-biphenyl Tetraformic dianhydride (Junkai Chemical) and 189.8g of p-phenylenediamine (Zhixin Chemical) were respectively added to the flask, and after stirring for 1.5 hours, 40.5g of polysiloxane (weight average molecular weight about 300, Longhui Chemical) Put it into the reaction system, stir and react for 3h; then put 172.7g of diethyl carbonate (TCI) into the reaction system, and stir for 60min to obtain the fiber-forming polymer solution; the prepared fiber-forming polymer solution , its solid content is 18.7% and its weight average molecular weight is 821,000.

[0056] Then, the fiber-forming solution is spun by the common dry-wet spinning method, the spinning temperature is 130°C, after passing through the coagulation bath, then through the water washing tank, and dried by hot air at 95°C at a draft ra...

Embodiment 3

[0058] Put 4100g of γ-butyrolactone into a four-necked flask, and raise the temperature to 70°C, and purge with nitrogen, the nitrogen flow rate is 3ml / min; then 460.3g of 2,3,3',4'-biphenyl Tetraformic dianhydride (Junkai Chemical), 162.6g of p-phenylenediamine (Zhixin Chemical) were added to the flask respectively, and after stirring for 1.5h, 40.5g of polysiloxane diethyl ester (weight average molecular weight about 300, quasi-biotechnology) into the reaction system, and then stirred for 3h; then 277.2g of diethyl carbonate (TCI) was put into the reaction system, and stirred for 60min to obtain a fiber-forming polymer solution; The fiber polymer solution has a solid content of 17.9% and a weight average molecular weight of 817,500.

[0059] Then, the fiber-forming solution is spun by the common dry-wet spinning method, the spinning temperature is 130°C, after passing through the coagulation bath, then through the water washing tank, and dried by hot air at 95°C at a draft r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com