Preparation method of alkaline-earth metal reinforced continuous aluminum silicate ceramic fiber

A technology of aluminum silicate ceramics and alkaline earth metals, which is applied in the field of preparation of continuous aluminum silicate ceramic fibers, can solve problems such as poor precursor gel spinning performance, and achieves simplified high-temperature calcination process, high mechanical tensile strength, The effect of maintaining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

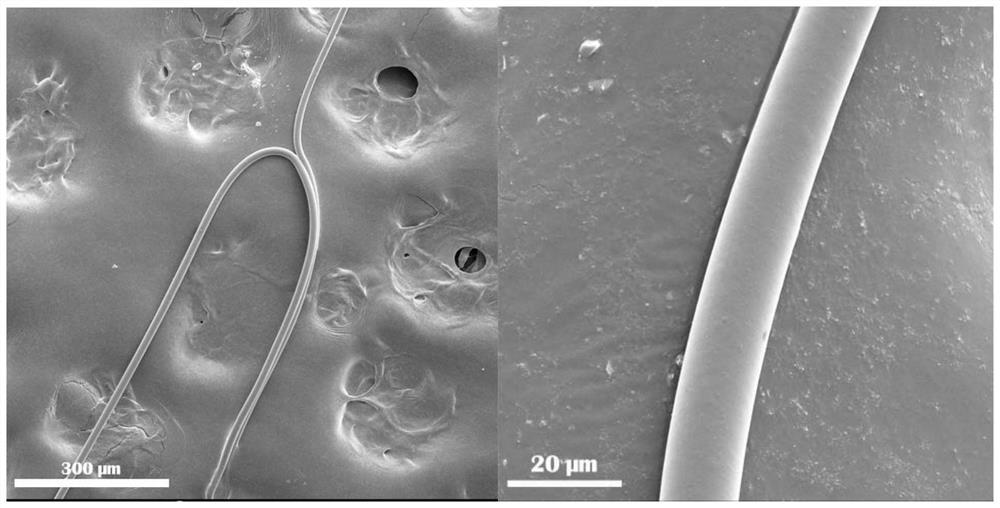

Image

Examples

Embodiment 1

[0030] A method for preparing continuous aluminum silicate ceramic fibers reinforced by alkaline earth metals, comprising the steps of:

[0031] S1: Dissolve and disperse 10 g of aluminum nitrate in 150 ml of water, and disperse for 2 hours under electric stirring under continuous ultrasonic conditions. Add 40 g of aluminum isopropoxide to the aluminum nitrate hydrolyzate, and disperse for 2 hours under electric stirring under continuous ultrasonic conditions. Then, electric stirring was continued at 60°C for 6 hours to obtain a mixed aluminum salt hydrolyzate.

[0032] S2: Add 20% calcium nitrate-magnesium nitrate mixed aqueous solution (molar ratio of calcium to magnesium: 1.2:1) to the above mixed aluminum salt hydrolyzate in the form of spray, the aqueous solution contains 15% PVP and EDTA disodium (PVP and EDTA disodium The mass ratio is 5: 1), and the spraying time is not shorter than 15 minutes to prevent the temperature fluctuation of the reaction system, and the mola...

Embodiment 2

[0039] A method for preparing continuous aluminum silicate ceramic fibers reinforced by alkaline earth metals, comprising the steps of:

[0040] S1: Dissolve and disperse 20 g of aluminum nitrate in 150 ml of water, and disperse for 3 hours under electric stirring under continuous ultrasonic conditions. Add 50 g of aluminum isopropoxide to the aluminum nitrate hydrolyzate, and disperse for 3 hours under electric stirring under continuous ultrasonic conditions. Then electric stirring was continued at 60°C for 8 hours to obtain a mixed aluminum salt hydrolyzate.

[0041] S2: Add 20% calcium nitrate-magnesium nitrate mixed aqueous solution (molar ratio of calcium to magnesium: 2:1) to the above-mentioned aluminum salt hydrolyzate in the form of spray, the aqueous solution contains 15% PVP and disodium EDTA (the mass of PVP and disodium EDTA Ratio of 3: 1), the spray addition time is not shorter than 15 min, in order to prevent the temperature fluctuation of the reaction system, ...

Embodiment 3

[0048] A method for preparing continuous aluminum silicate ceramic fibers reinforced by alkaline earth metals, comprising the steps of:

[0049] S1: Dissolve and disperse 10 g of aluminum nitrate in 150 ml of water, and disperse for 2 hours under electric stirring under continuous ultrasonic conditions. Add 40 g of aluminum isopropoxide to the aluminum nitrate hydrolyzate, and disperse for 2 hours under electric stirring under continuous ultrasonic conditions. Then, electric stirring was continued at 60°C for 6 hours to obtain a mixed aluminum salt hydrolyzate.

[0050] S2: Add 20% calcium nitrate-magnesium nitrate-strontium nitrate mixed aqueous solution (molar ratio of calcium to magnesium and strontium 1.2 : 0.6 : 0.6) in the form of spray to the above mixed aluminum salt hydrolyzate, the aqueous solution contains 15% PVP and disodium EDTA (The mass ratio of PVP to disodium EDTA is 3: 1), and the spraying time should not be shorter than 15 minutes to prevent the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com