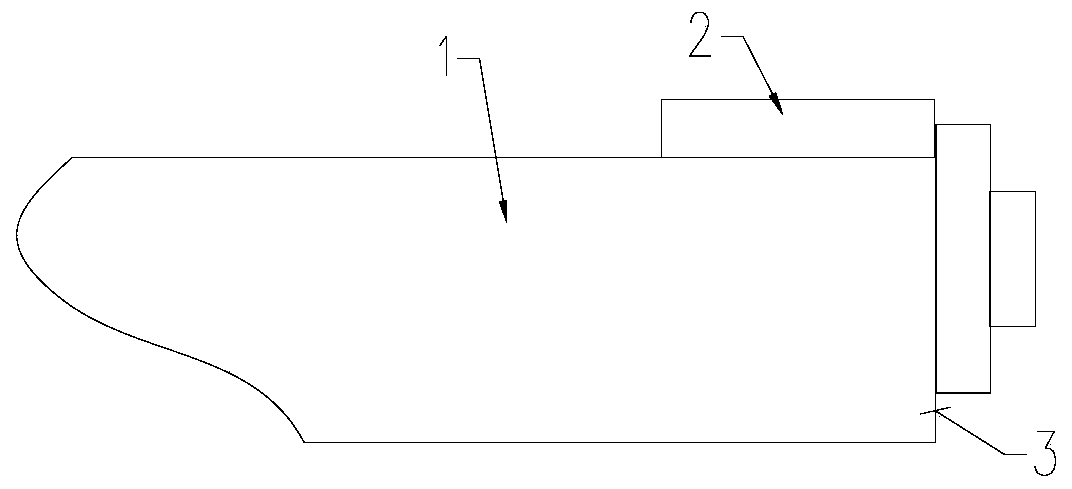

Installation construction method of high-speed wire rod finishing mill

A technology of high-speed wire rod and construction method, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of large error, block gauge error, deviation, etc., and reduce the probability of quality defects , Compress the construction period and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

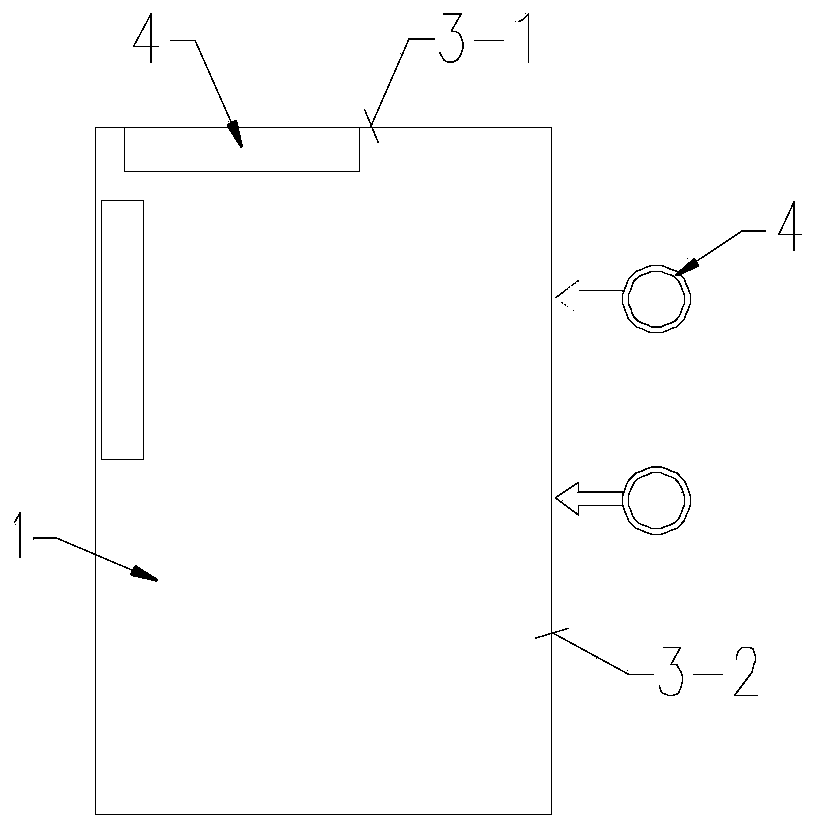

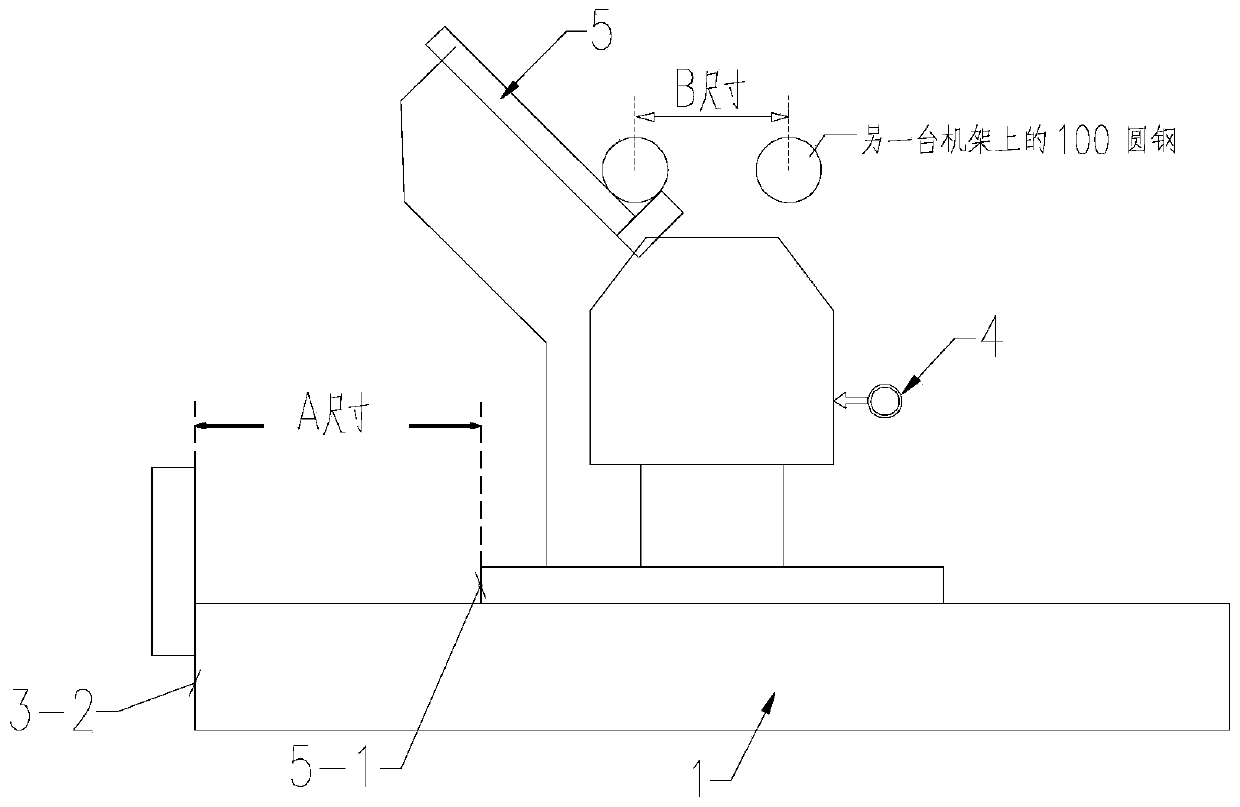

Method used

Image

Examples

Embodiment Construction

[0090] Generally speaking, the installation and adjustment construction process of the high-speed wire rod finishing mill, the main installation process is as follows: basic acceptance - measurement and setting out - basic retesting - foundation treatment - installation of adjustable grouting pad iron - rough adjustment of the rolling mill base - primary grouting of the rolling mill base - rolling mill base Fine adjustment - secondary grouting of rolling mill base - fine adjustment of inclined support installation - fine adjustment of short axis side cone box and roller box installation - coarse adjustment of synchronous gearbox - primary grouting of synchronous gearbox - fine adjustment of synchronous gearbox - long axis side cone box And fine adjustment of roller box installation - secondary grouting of synchronous gearbox - rough adjustment of main motor - primary grouting of main motor - fine adjustment of main motor - secondary grouting of main motor.

[0091] The overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com