Molten salt storage tank heat exchange system

A heat exchange system and storage tank technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat storage equipment, etc., can solve the problems of short life of heating devices, large impact on storage tank design, complex layout structure, etc., and achieve installation Low manufacturing cost, controllable cooling process, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the molten salt storage tank heat exchange system of the present invention will be described below through specific embodiments. Unless otherwise specified, the technical means used in the present invention are methods known to those skilled in the art. In addition, the embodiments should be considered as illustrative rather than limiting the scope of the invention, the spirit and scope of which is defined only by the claims. For those skilled in the art, without departing from the essence and scope of the present invention, various modifications and improvements made to the technical solution of the present invention also belong to the protection scope of the present invention.

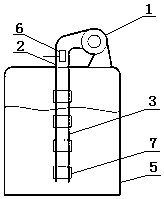

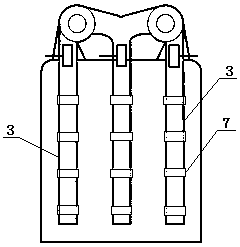

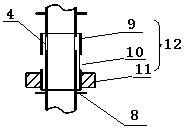

[0037] Such as figure 1 As shown, the molten salt storage tank heat exchange system of the present invention includes a molten salt storage tank 5, and also includes a heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com