High-efficiency and energy-saving extraction tank

A high-efficiency, energy-saving, extraction tank technology, which is applied in the direction of making medicines into special physical or ingestible devices, can solve the problems of long pre-boiling time, unreasonable heat distribution, and low heat transfer efficiency, and achieve the goal of shortening boiling time, less steam consumption, enhanced effect of convection heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

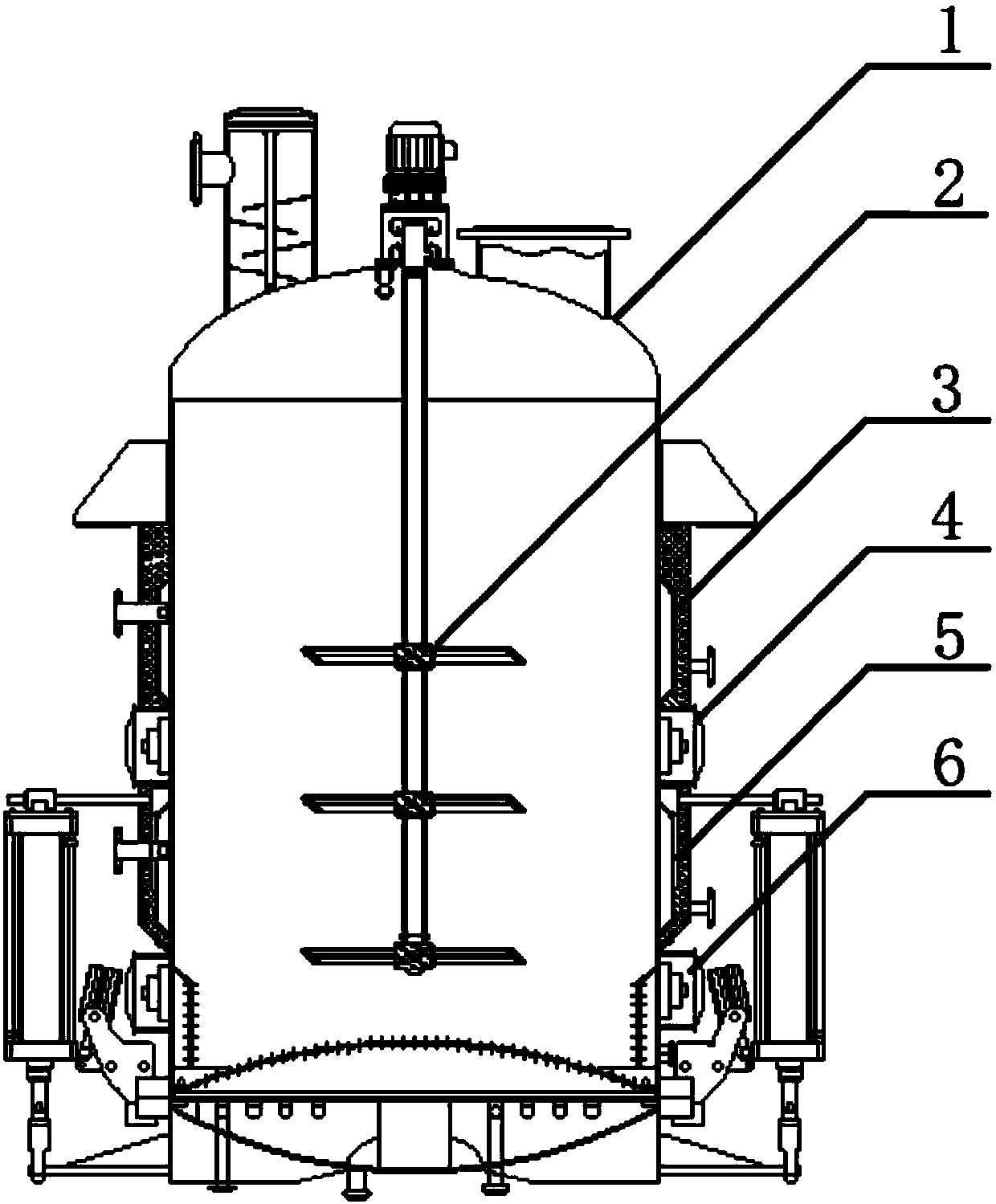

[0025] Example 1 High-efficiency and energy-saving extraction tank structure and operation process

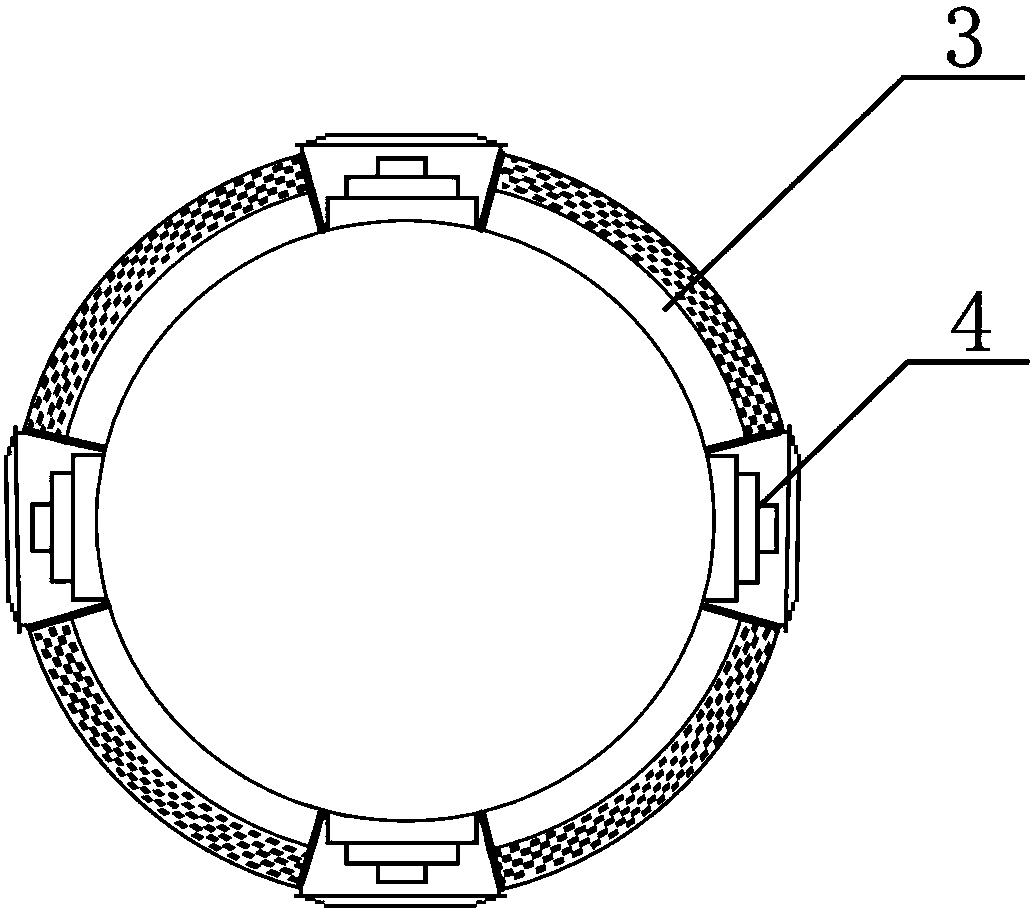

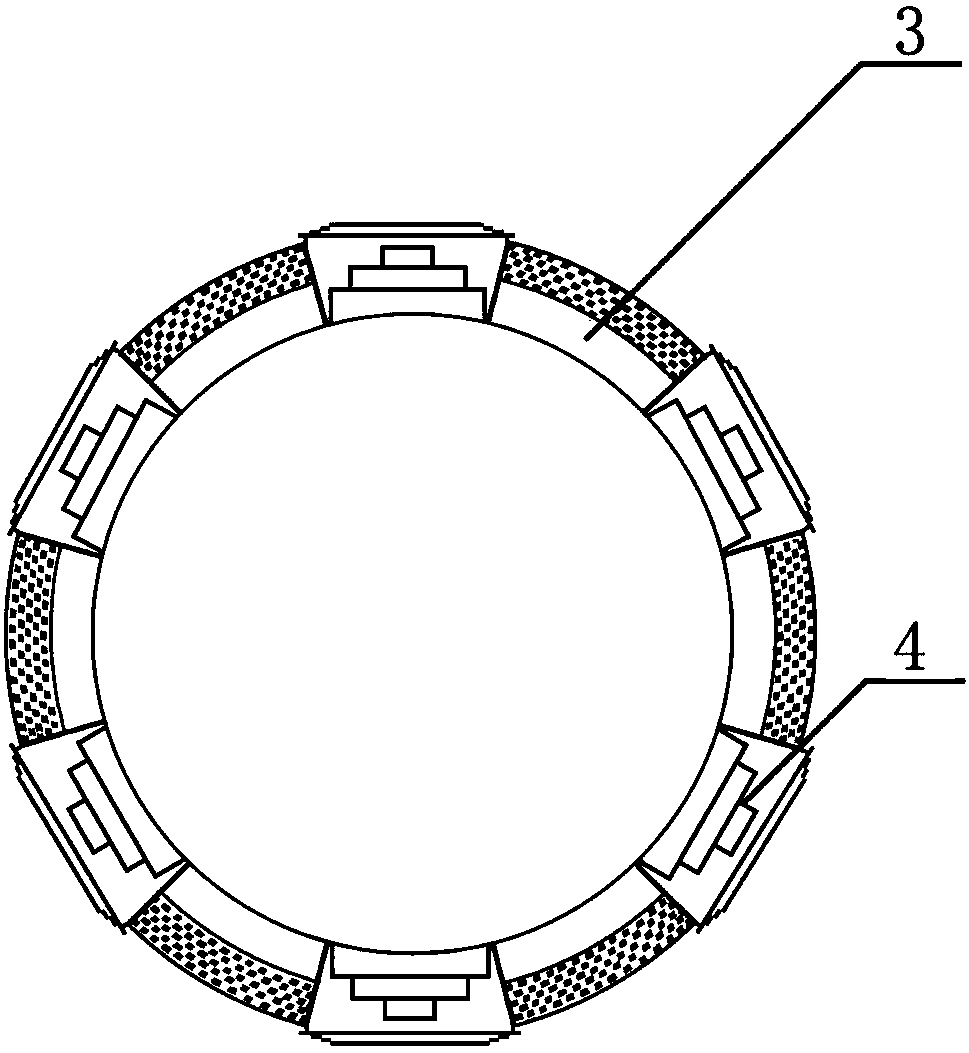

[0026] As attached figure 1 As shown, the main components of the extraction tank of the present invention include the body 1, the stirring blade 2, the upper heating jacket 3 and the lower heating jacket 5, which have the same or similar structure as the existing extraction tank. The outer wall of the tank 1 is provided with an upper ultrasonic transducer 4 and a lower ultrasonic transducer 6, the upper ultrasonic transducer 4 is a group of 6, and the lower ultrasonic transducer 6 is a group of six, all cylindrical The arc structure is inlaid on the upper and lower parts of the outer wall of the tank 1, and is arranged alternately along the outer wall of the tank 1 in a bottom-up order.

[0027] During the extraction of Chinese herbal medicine pieces, the Chinese herbal medicine pieces and the extraction solvent are added to the tank 1 in proportion. When heating is started in the f...

Embodiment 2

[0028] Example 2 High-efficiency and energy-saving extraction tank structure and operation process

[0029] As attached figure 1 As shown, the main components of the extraction tank of the present invention include the body 1, the stirring blade 2, the upper heating jacket 3 and the lower heating jacket 5, which have the same or similar structure as the existing extraction tank. The outer wall of the tank 1 is provided with an upper ultrasonic transducer 4 and a lower ultrasonic transducer 6, the upper ultrasonic transducer 4 is a group of 4, and the lower ultrasonic transducer 6 is a group of 4, all cylindrical The arc structure is inlaid on the upper and lower parts of the outer wall of the tank 1, and is arranged alternately along the outer wall of the tank 1 in a bottom-up order.

[0030] During the extraction of Chinese herbal medicine pieces, the Chinese herbal medicine pieces and the extraction solvent are added to the tank 1 in proportion. When heating is started in the fir...

Embodiment 3

[0031] Example 3 Comparison test of extraction energy consumption in high efficiency and energy saving extraction tank

[0032] The high-efficiency and energy-saving extraction tank of the present invention (the effective extraction volume of the extraction tank is 3m 3 , The upper ultrasonic transducer 4 and the lower ultrasonic transducer 6 are in groups of 6) decocting 2000kg of purified water, a total of 6 sets of experiments are set up, of which the first, second, and third sets of experiments turn on the upper and lower ultrasonic waves Transducers, the 4th, 5th, and 6th group tests close the upper and lower ultrasonic transducers.

[0033] The steam pressure and temperature used in the 6 groups of tests remained the same, and the opening sizes of the steam valves of the upper heating jacket 3 and the lower heating jacket 5 were also the same. The initial temperature of the purified water used in the 6 groups of experiments was 22°C. When the temperature of the purified water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com