Visual detecting system for composite filter rod section lengths

A composite filter rod and visual inspection technology, applied in sorting and other directions, can solve the problems of combination of defective product rejection functions and low use efficiency, and achieve the effect of reducing manual workload, compact structure and high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

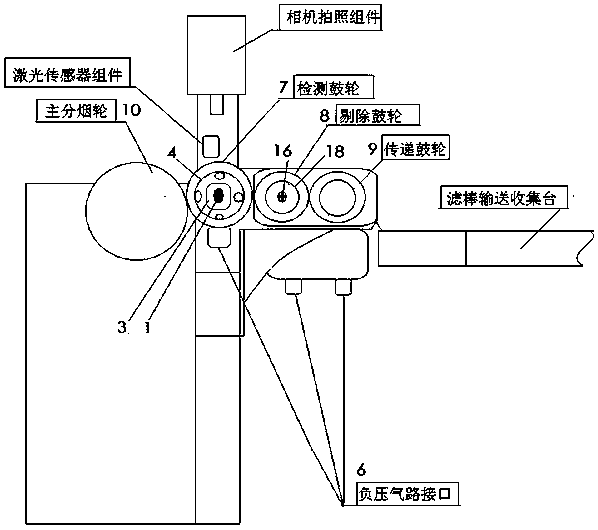

[0029] Such as figure 1 The visual inspection system for the segment length of the composite filter rod shown has a detection drum, a rejecting drum, a transfer drum, and a filter rod collecting and conveying assembly that are sequentially connected to the smoke separating wheel of the filter rod forming machine. machine vision system.

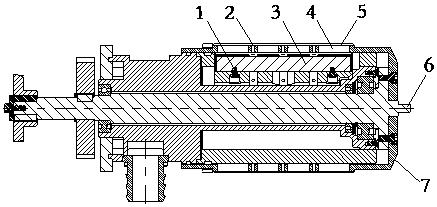

[0030] The detection drum is composed of a detection drum shell, a spectroscope, a visual imaging diaphragm, and a high-light light source in the order from outside to inside; wherein, the spectroscope is close to the inside of the test drum shell, and the part of each spectroscope There are several through holes, and the inner side of each through hole is connected with a negative pressure air path, which is convenient for absorbing the filter rod.

[0031] The high-gloss light source can provide high-brightness illumination, and through the visual imaging diaphragm, the concentrated light source of the high-gloss light source can be turned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com