Subway car end underframe structure

A technology for subway cars and underframes, which is applied to railway car body parts, underframes, and wheel guards/buffers for railway vehicles, etc. Avoid excessive local force, improve space utilization, and improve the effect of force conduction paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

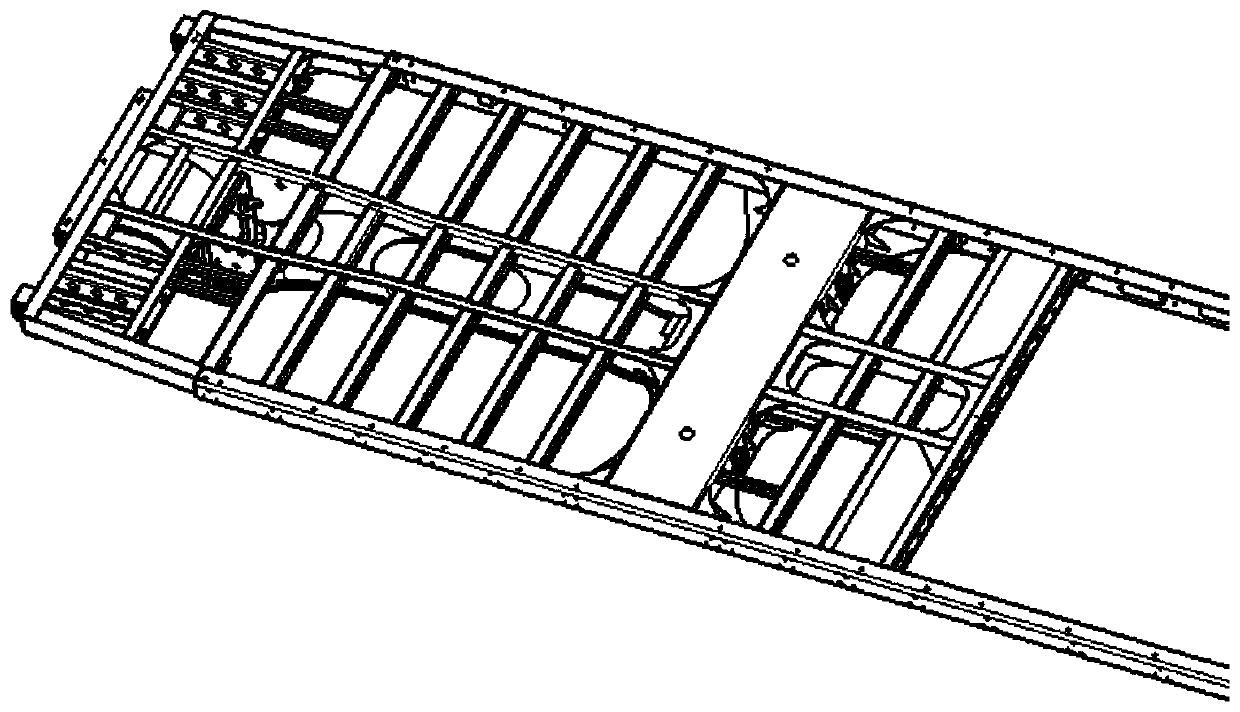

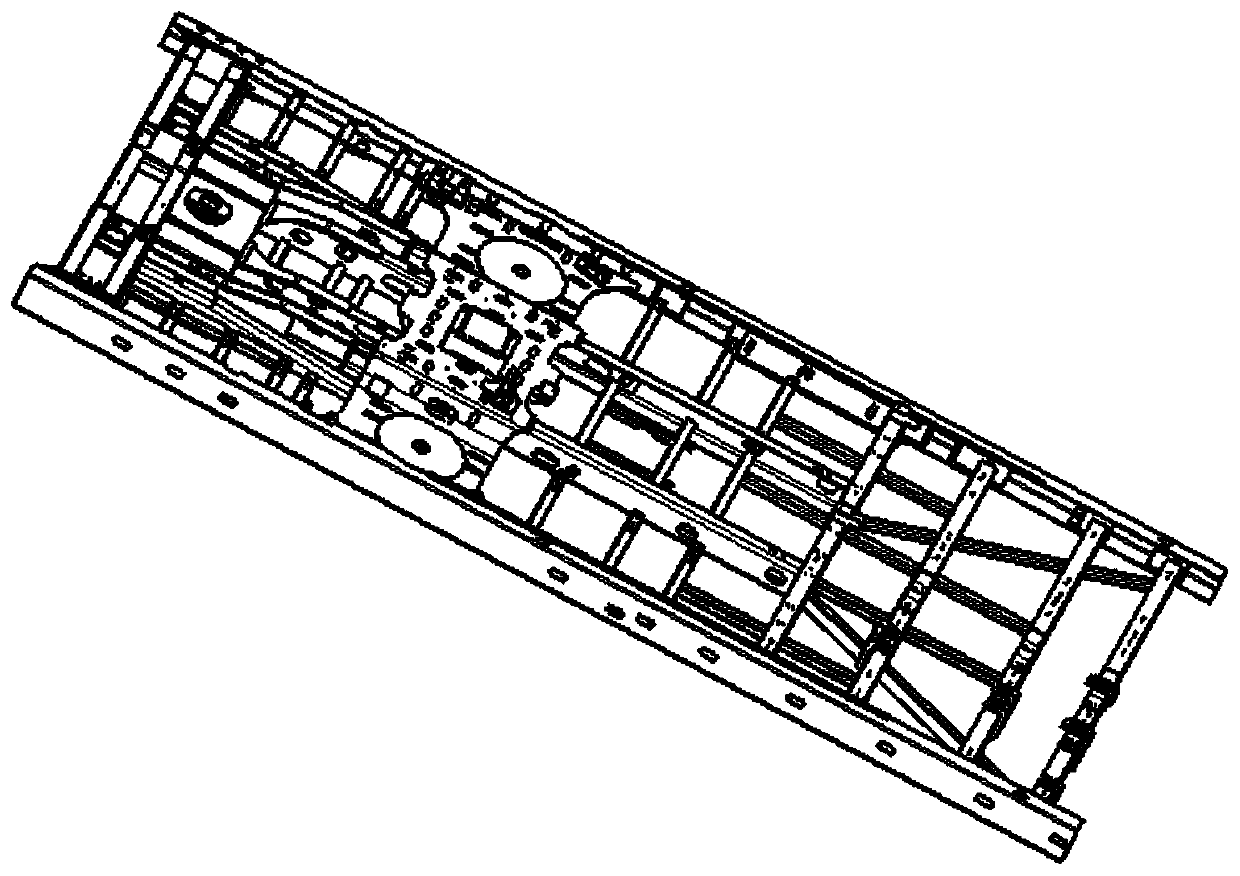

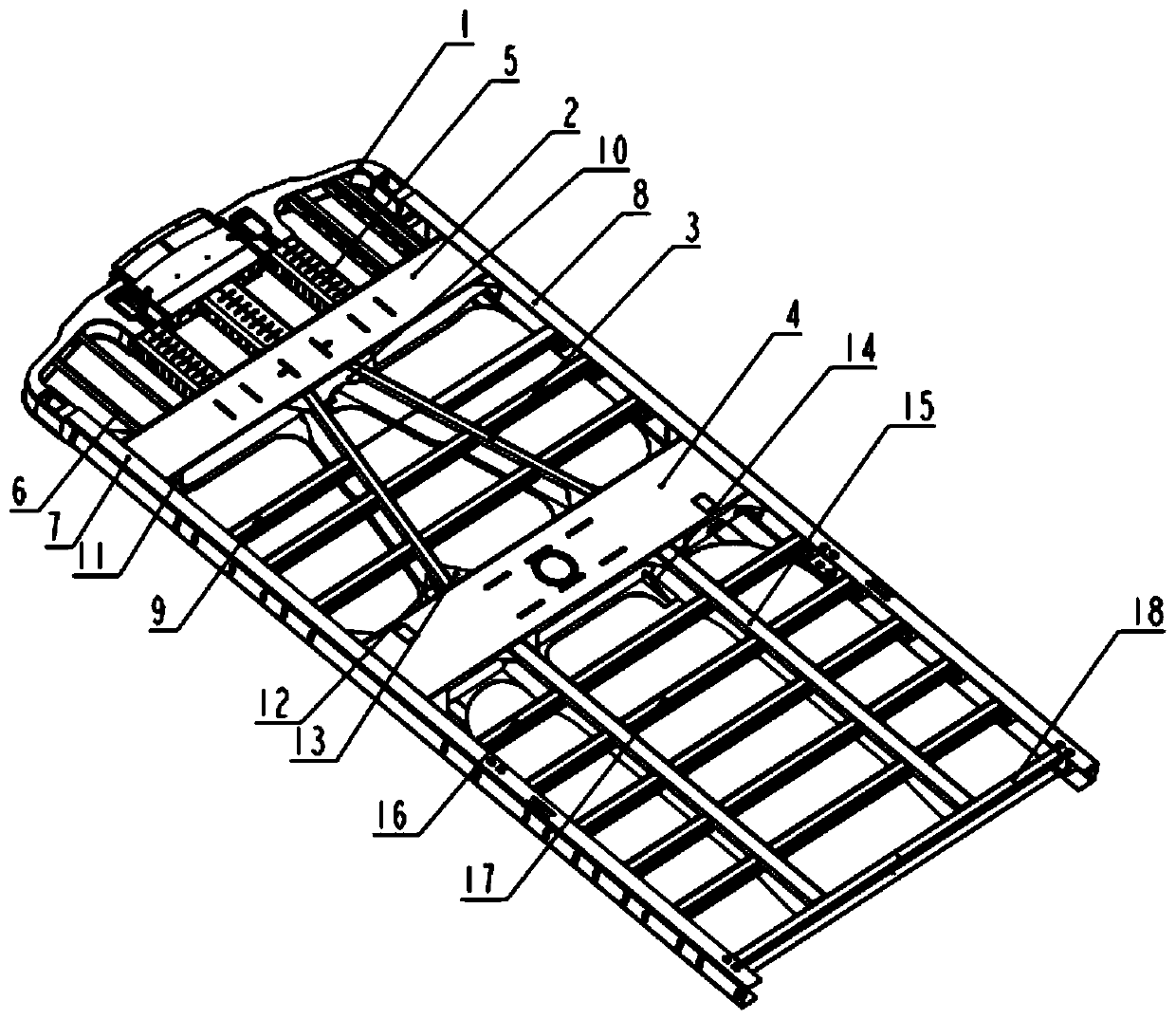

[0023] refer to image 3 , the composition of the end underframe in the present invention includes: front anti-climbing device composition 1, coupler seat composition 2, buffer beam composition 3, corbel composition 4, crush box composition 5, connecting beam 6, left carbon steel side beam Composition 7, right carbon steel side beam composition 8, inclined floor beam 9, special-shaped patch 10, patch 11, vertical panel 12, isosceles patch 13, stiffener plate 14, longitudinal beam composition 15, floor beam 16, long Floor beam 17, main beam 18. The front anti-climbing device consists of 1 to prevent the car body from climbing up during the vehicle collision process, and the two ends are welded to the left carbon steel side beam composition 7 and the right carbon steel side beam composition 8; the crush box composition 5 is welded to the front end anti-climbing device. Between the crawler component 1 and the coupler seat component 2, when the vehicle collides, deformation occur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com