Preparation of CdSeZnS/ZnS/ZnS core/shell/core quantum dot

A technology for quantum dots and quantum dot solution, which is applied in the field of quantum dot preparation, can solve problems such as the inability to meet usage requirements, and achieve the effects of narrow half-height width, low cadmium content, and uniform size and morphology

Active Publication Date: 2019-08-16

SHANGHAI JIAO TONG UNIV

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

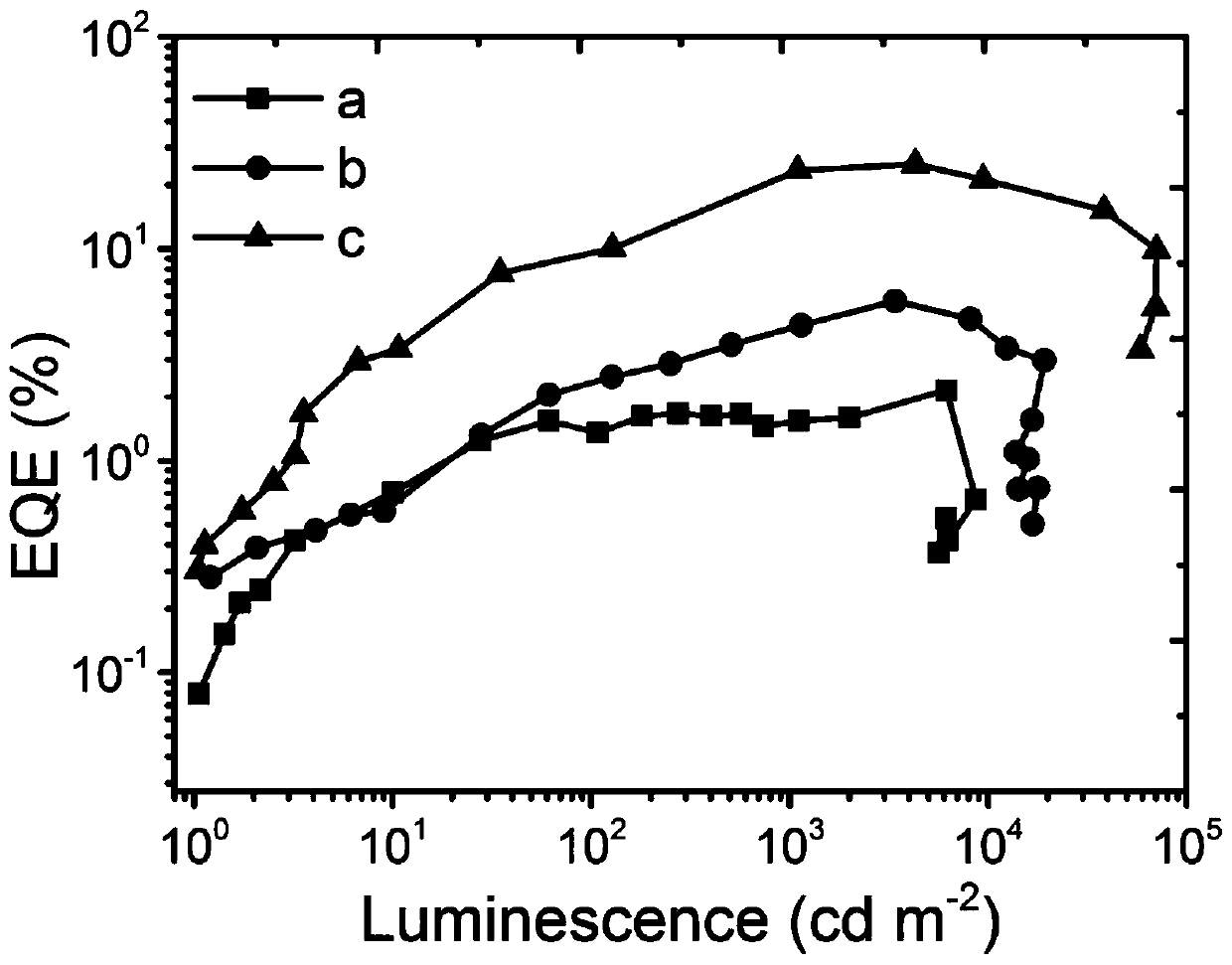

Although the maximum external quantum efficiencies of inverted red, green, and blue quantum dot diodes reach 20.74, 22.4, and 8.38% respectively, the lifetimes of current devices are less than 300h, which cannot meet the requirements of use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0042] Example 1. Preparation of Green Light CdSeZnS / ZnS / ZnS Core / Shell / Shell Quantum Dots

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

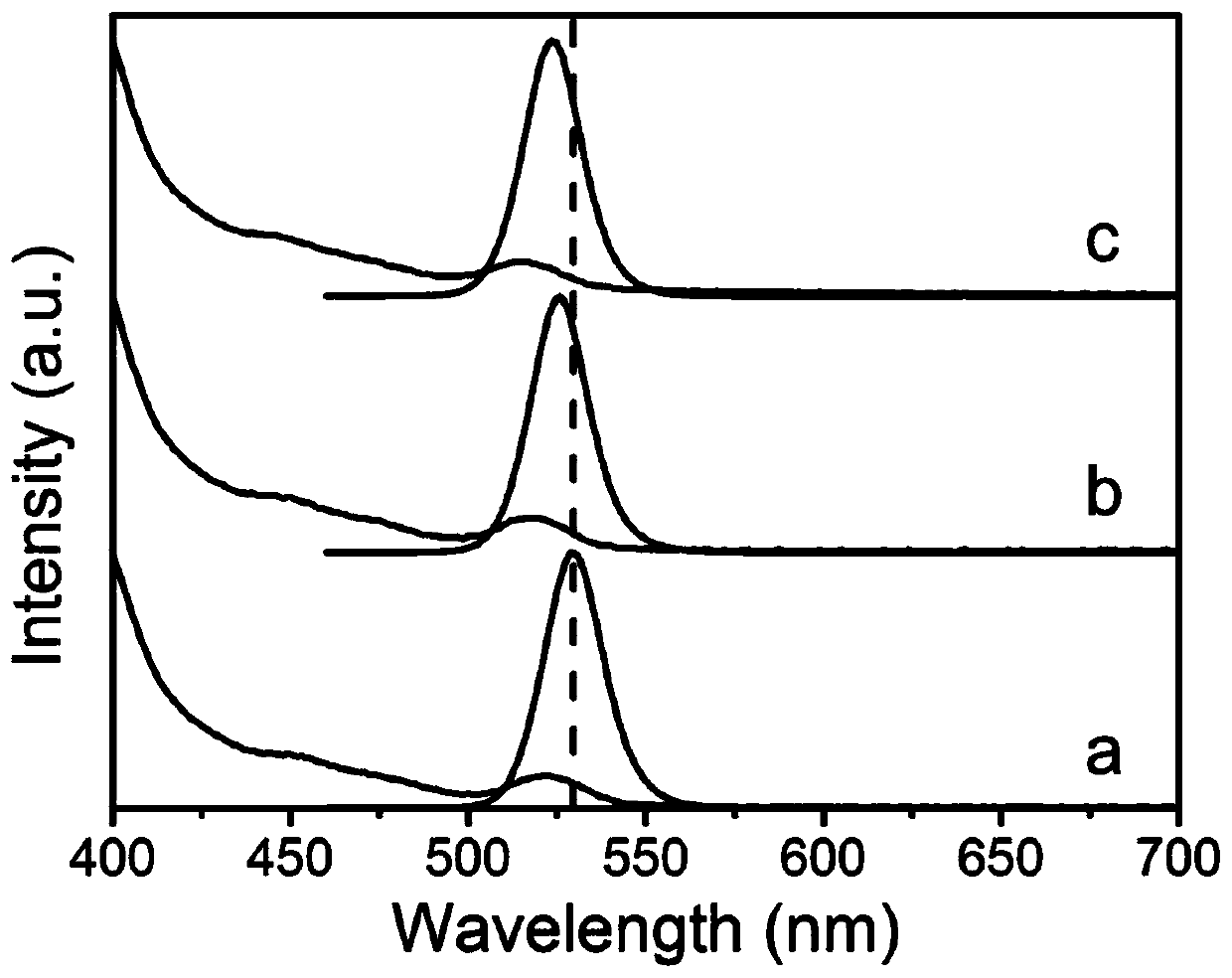

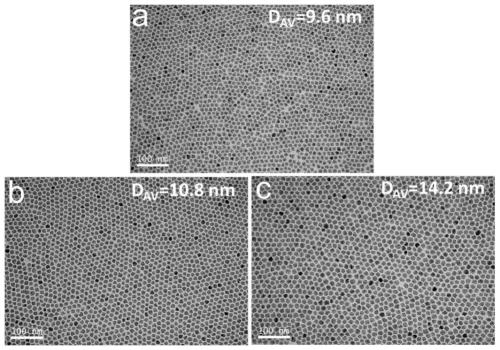

The invention provides preparation of a CdSeZnS / ZnS / ZnS core / shell / core quantum dot. The preparation comprises following steps: reacting a cadmium source and a zinc source with oleic acid and 1-octadecene to prepare a cation precursor; reacting a selenium source and a sulfur source with trioetyl phosphine to prepare an anion precursor; rapidly injecting the anion precursor into the cation precursor at a certain temperature to carry out reactions to obtain a quantum dot core; using an injection pump, controlling the shell growth temperature, the shell precursor injection amount, and injection speed, growing a first layer prepared from zinc oleate and octyl mercaptan, and growing a second layer prepared from oleylamine zinc and oleylamine sulfur to obtain the CdSeZnS / ZnS / ZnS green light core / shell / core quantum dot. The prepared quantum dot has the advantages of uniform size and morphology, low half-width, high fluorescence efficiency, and low cadmium content, is widely applied to the fields of illumination and display, is especially suitable for a full solution inverted device structure, and is capable of largely improving the device efficiency and prolonging the service life.

Description

technical field [0001] The invention relates to the field of quantum dot preparation, in particular to the preparation of green light CdSeZnS / ZnS / ZnS core / shell / shell quantum dots for an inverted light-emitting diode with high efficiency and long life. Background technique [0002] Quantum dots are semiconductor nanoparticles with a particle size between 1-20nm, and their properties are mainly determined by their composition, size, and shape. When the radius of the quantum dot is smaller than the Bohr radius, it exhibits a strong quantum confinement effect. By adjusting the particle size of quantum dots, the emission wavelength can be adjusted. By performing ligand exchange and shell growth on the surface of quantum dots, the stability and luminescent performance of the material can be improved. After the improvement of the synthesis method, quantum dot materials with luminous efficiency of 100% have been reported. Quantum dots have broad application prospects in liquid c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K11/88B82Y20/00B82Y30/00B82Y40/00

CPCB82Y20/00B82Y30/00B82Y40/00C09K11/883

Inventor 李万万杨志文周小川林拱立武卫杰

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com