Fireproof material of using inorganic salts-free radical quenching agent to inhibit spontaneous combustion of coal and preparation method thereof

A fireproof material and free radical technology, applied in fireproof equipment and other directions, can solve the problems of increasing the difficulty of using chemical inhibitors, increasing the cost of use, and short resistance life, and achieving long-lasting and high-efficiency coal spontaneous combustion fire prevention, increased bonding, and resistance long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

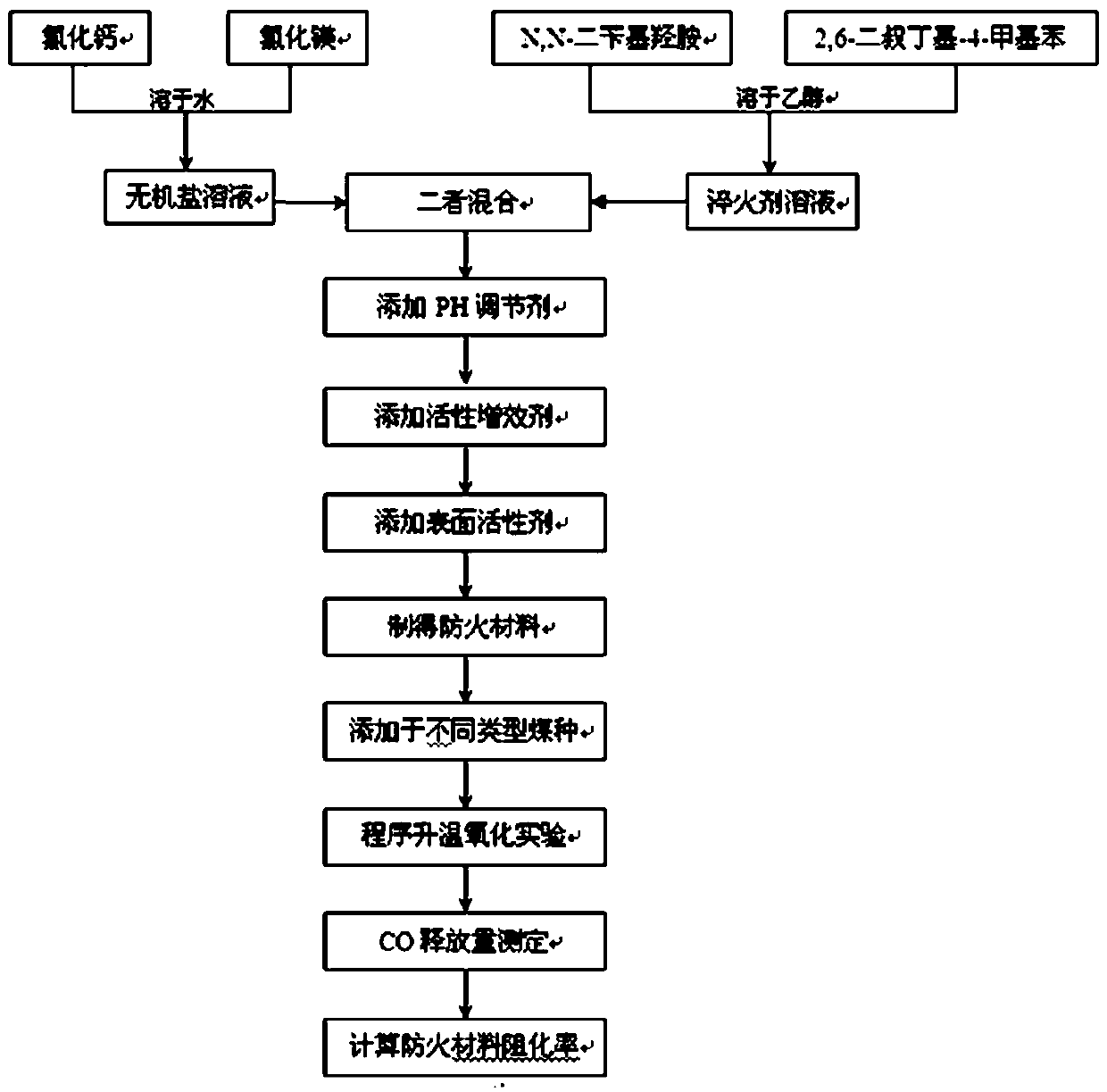

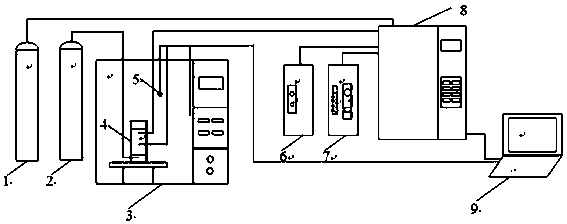

Method used

Image

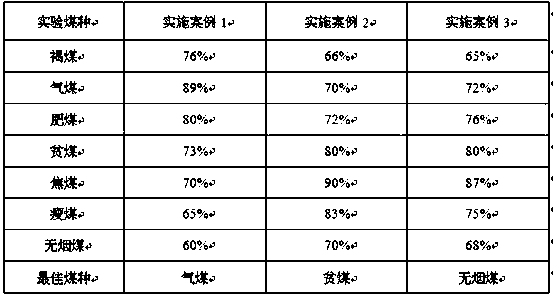

Examples

Embodiment 1

[0027] (1) Take 50 parts of magnesium chloride and 70 parts of calcium chloride and slowly add them to 900 parts of distilled water, and stir continuously until they are completely dissolved. Heat will be generated during the stirring process, and the heat will be dissipated by standing still.

[0028] (2) Dissolve 30 parts of N,N-dibenzylhydroxylamine (DBHA) and 50 parts of 2,6-di-tert-butyl-4-methylphenol (BHT) powder in 50ml of ethanol with a concentration of 60-70% solution, and stir well.

[0029] (3) Mix the solutions prepared in step 1 and step 2, and slowly add 10 parts of NaHCO to the mixture 3 , Stir well to keep the pH between 6-7.

[0030] (4) Add 30 parts of sodium citrate activity enhancer and 10 parts of sodium lauryl sulfate surfactant to the prepared mixed solution, and stir thoroughly to obtain the inorganic salt-free radical quenching described in the present invention It is a fireproof material that double suppresses the spontaneous combustion of coal.

Embodiment 2

[0032] (1) Take 60 parts of magnesium chloride and 40 parts of calcium chloride and slowly add them to 950 parts of distilled water, and stir continuously until they are completely dissolved. Heat will be generated during the stirring process, and the heat will be dissipated by standing still.

[0033] (2) Dissolve 40 parts of N,N-dibenzylhydroxylamine (DBHA) and 30 parts of 2,6-di-tert-butyl-4-methylphenol (BHT) powder in 50ml of ethanol with a concentration of 60-70% solution, and stir well.

[0034] (3) Mix the solutions prepared in step 1 and step 2, and slowly add 10 parts of NaHCO to the mixture 3 , Stir well to keep the pH between 6-7.

[0035] (4) Add 30 parts of sodium citrate activity enhancer and 20 parts of sodium lauryl sulfate surfactant to the prepared mixed solution, and stir thoroughly to obtain the inorganic salt-free radical quenching described in the present invention It is a fireproof material that double suppresses the spontaneous combustion of coal.

Embodiment 3

[0037] (1) Take 50 parts of magnesium chloride and 50 parts of calcium chloride and slowly add them into 1000 parts of distilled water, and stir continuously until they are completely dissolved. Heat will be generated during the stirring process, and the heat will be dissipated by standing still.

[0038] (2) Dissolve 50 parts of N,N-dibenzylhydroxylamine (DBHA) and 20 parts of 2,6-di-tert-butyl-4-methylphenol (BHT) powder in 50ml of ethanol with a concentration of 60-70% solution, and stir well.

[0039] (3) Mix the solutions prepared in step 1 and step 2, and slowly add 8 parts of NaHCO to the mixture 3 , Stir well to keep the pH between 6-7.

[0040] (4) Add 20 parts of sodium citrate activity enhancer and 20 parts of sodium lauryl sulfate surfactant to the prepared mixed solution, and stir thoroughly to obtain the inorganic salt-free radical quenching described in the present invention It is a fireproof material that double suppresses the spontaneous combustion of coal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com