Method for preventing spontaneous combustion of residual coal in goaf during end mining-stopping and withdrawing period of working face

A technology for gobs and working faces, which is applied in dust prevention, mining equipment, earthwork drilling, etc. It can solve the problems of ignoring the fire prevention and extinguishing effect of modern new materials, long support removal period, and slow mining speed, etc., to achieve plugging Effect of inerting on suppressing high temperature point of residual coal and prolonging spontaneous combustion period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

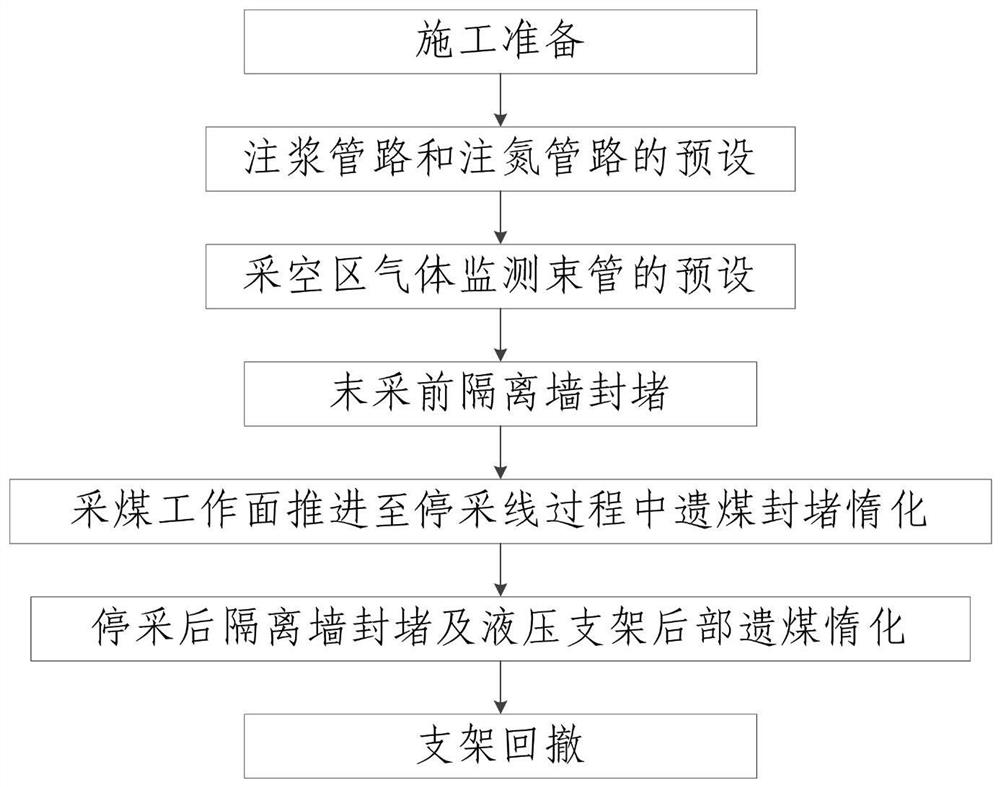

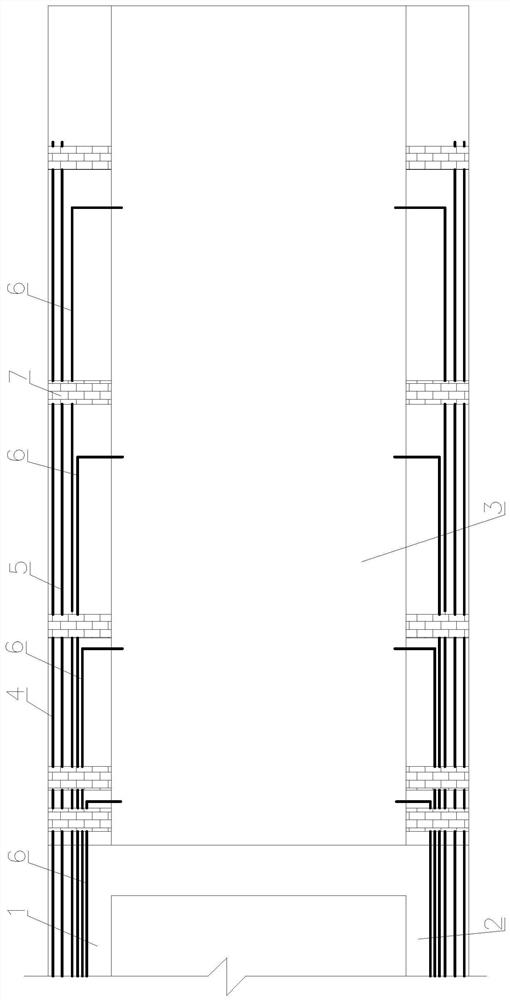

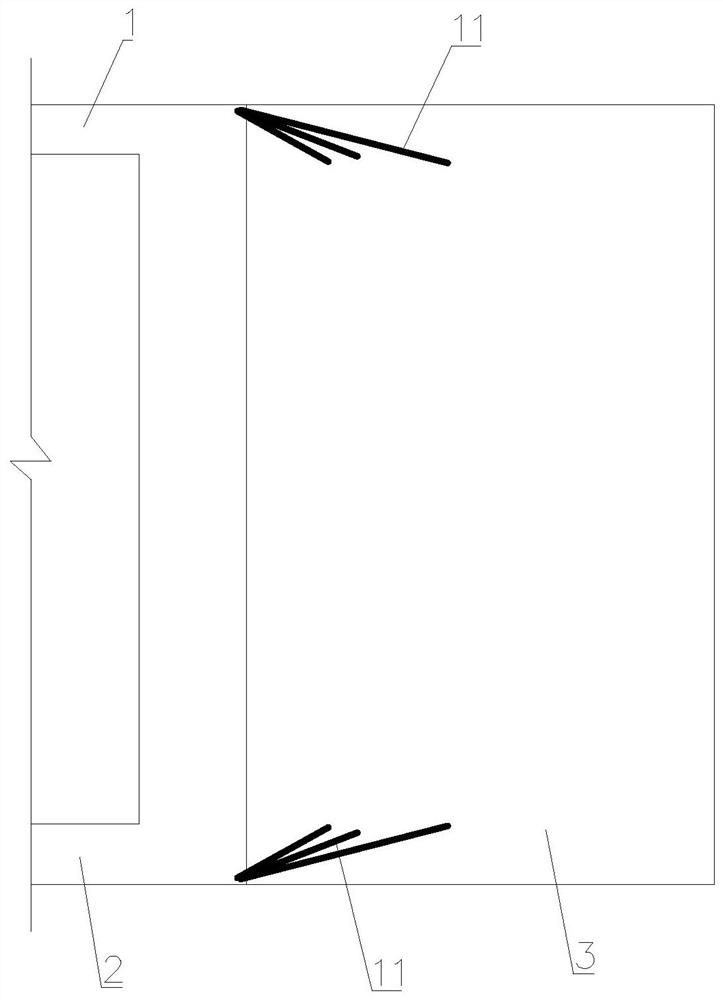

[0043] Such as Figure 1 to Figure 4 A method for preventing and controlling the spontaneous combustion of leftover coal in the goaf during the end-mining-stop withdrawal of the working face shown, the method includes the following steps:

[0044] Step 1. Construction preparation: before final mining, according to the goaf spontaneous combustion three-zone division standard, the coal seam geological structure area, high temperature between working face frames, and gas anomalies (CO, C 2 h 6 etc.) areas, air inlet lanes and return air lanes to predict the dangerous areas prone to coal spontaneous combustion, and divide the key areas for fire prevention and extinguishment in the final mining stage, that is, the separation wall construction area, grouting area and nitrogen injection area. In the construction area of the separation wall, signage shall be placed at the position where the separation wall needs to be constructed in the air inlet lane and the return air lane;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com