Forming and quality improving method for brown coal

A technology for lignite and briquette, which is applied in the fields of lignite molding and quality improvement and coal deep processing of lignite molding and quality improvement, can solve the problems of immature technology, serious environmental pollution, large project investment, etc., and achieves prolonged spontaneous combustion and ignition period, simple process, The effect of lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

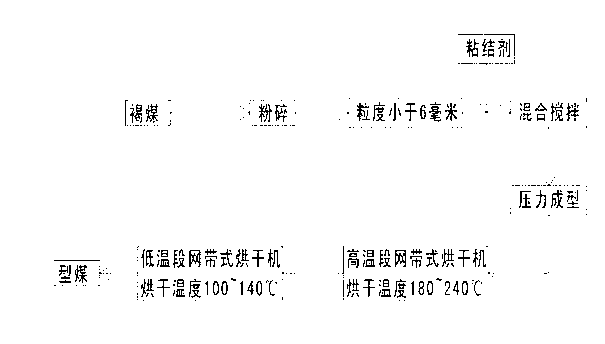

[0012] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0013] In the embodiment, firstly, the lignite with a low calorific value of 13.4 MJ / kg, a total moisture of 44.7%, an ash content of 8.44%, and a volatile content of 30.03% tested by a third-party measurement and inspection department is pulverized to below 6 mm, and its moisture content is adjusted to 45%, and then carry out pressure forming, the described forming process, add adhesive after lignite pulverization, mix and stir evenly, carry out pressure forming again.

[0014] The molded coal is sent to the mesh belt dryer for drying. The drying heat source of the mesh belt dryer is the furnace flue gas. The mesh belt dryer is divided into two groups of front and rear. The type dryer is a high-temperature section, and the rear mesh belt dryer is a low-temperature section. The front and rear sections are dried at different temperatures. The dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com