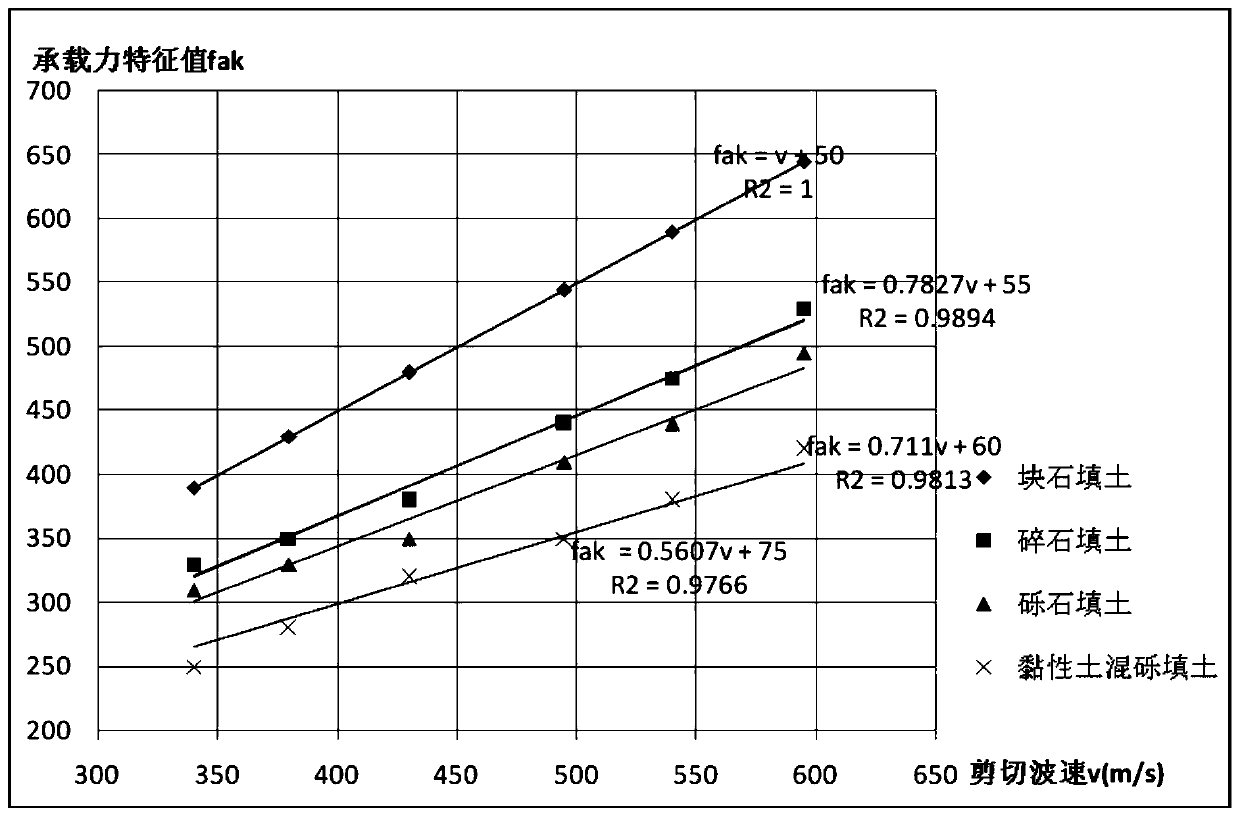

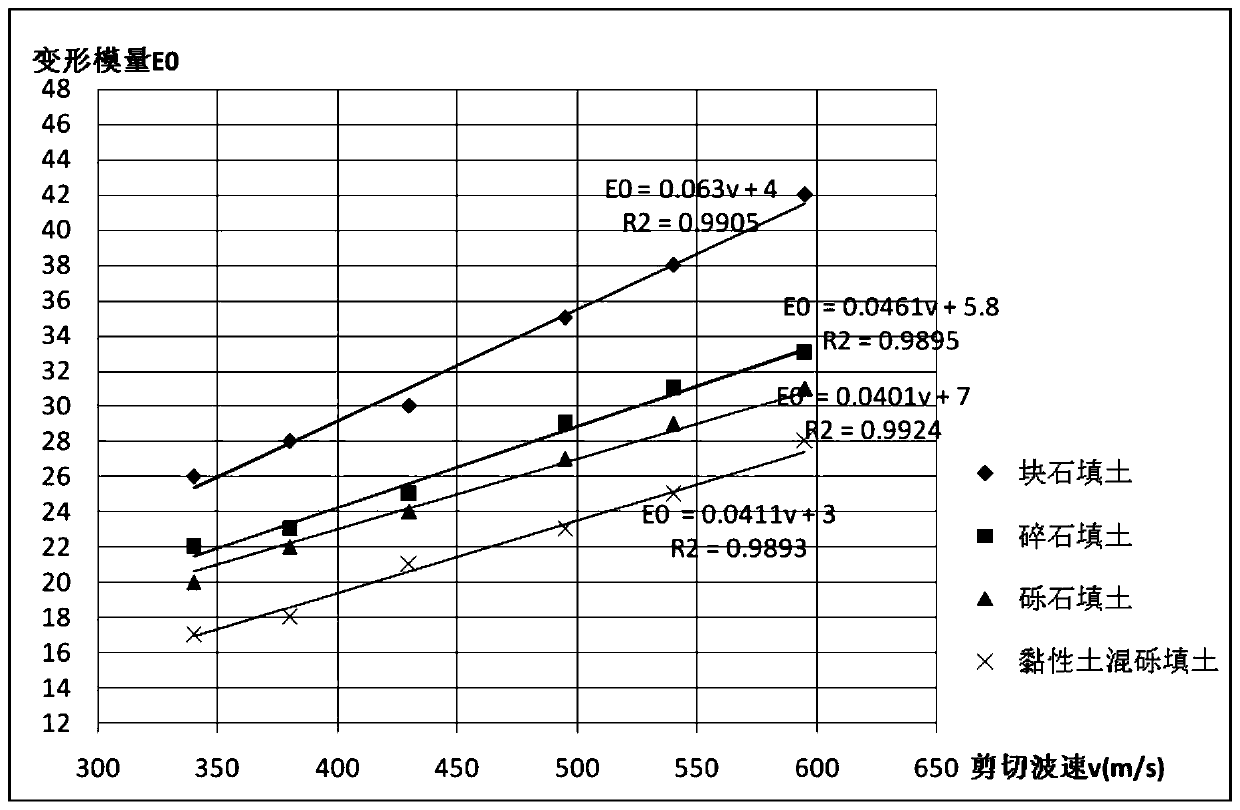

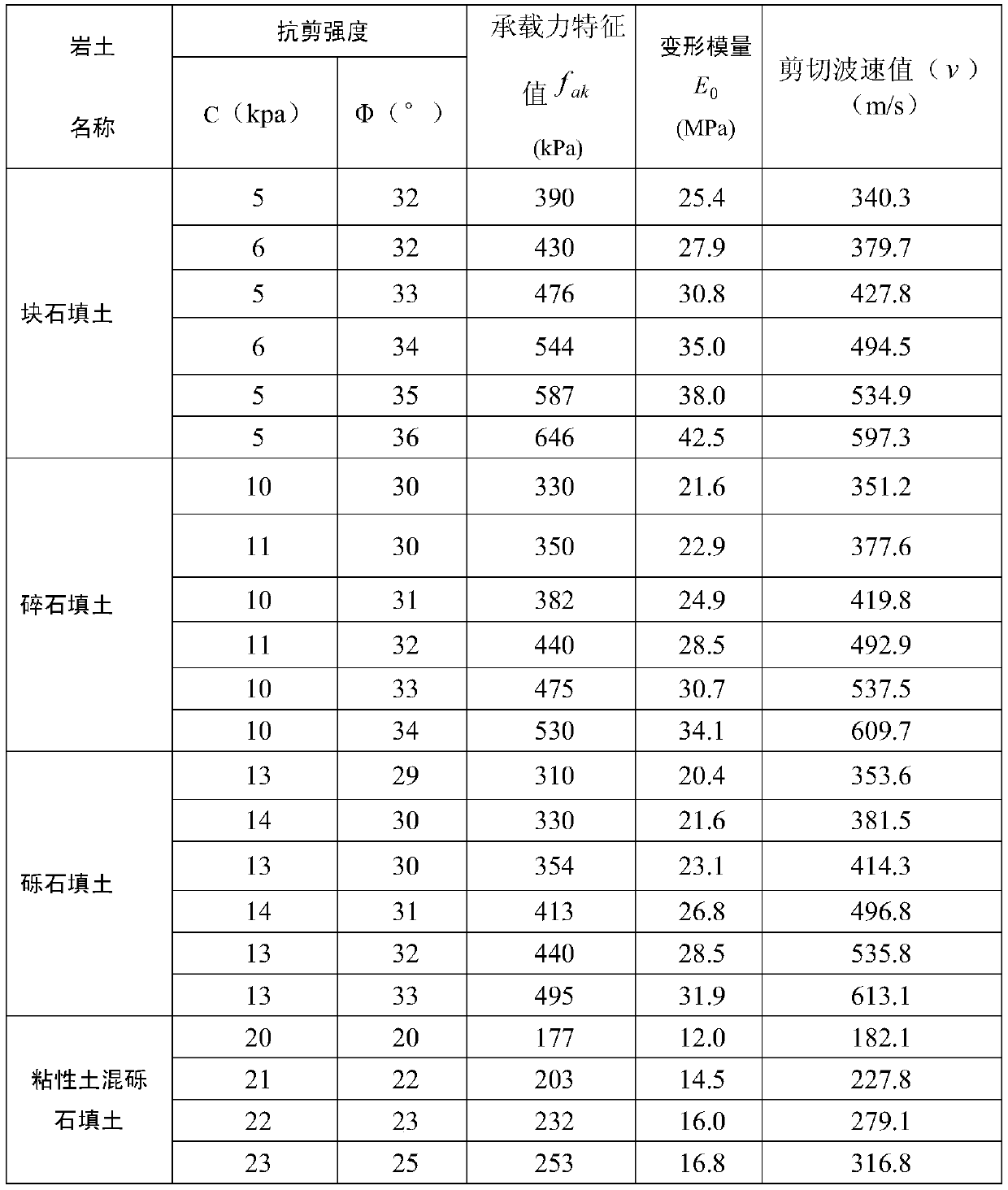

Method for determining bearing capacity characteristic values of tamped/compacted fill strata by using shear wave velocity

A technology of bearing capacity eigenvalues and shear waves, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve problems such as large differences in physical and mechanical indicators, and achieve the effect of simple calculation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0081] Implementation case: Maanshan Iron and Steel Co., Ltd. Port Raw Materials Yard A~E The upper filling layer of the material strip site has been treated with dynamic compaction foundation and has been piled up during the use of many years of material strips. Due to the requirements of environmental protection upgrades and intelligent transformation, it is planned to build on the raw material strips C-type material strip, C-type material strip is particularly sensitive to settlement and deformation. For the design of C-type material strip foundation, it is necessary to provide the characteristic value of bearing capacity and deformation modulus of about 4m thick rammed (compressed) compacted filling soil layer. Due to the tight schedule, it will take a lot of time and financial resources to use the traditional load test and on-site direct shear test. Therefore, in the geotechnical engineering investigation, the characteristic value of the bearing capacity and the deformation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com