Outer wall really stone paint spraying device

A spraying device and real stone paint technology, applied in the direction of architecture and building construction, can solve the problems of raw material waste, long time-consuming, large polishing area, etc., and achieve the effects of ensuring efficiency, realizing effective integration, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

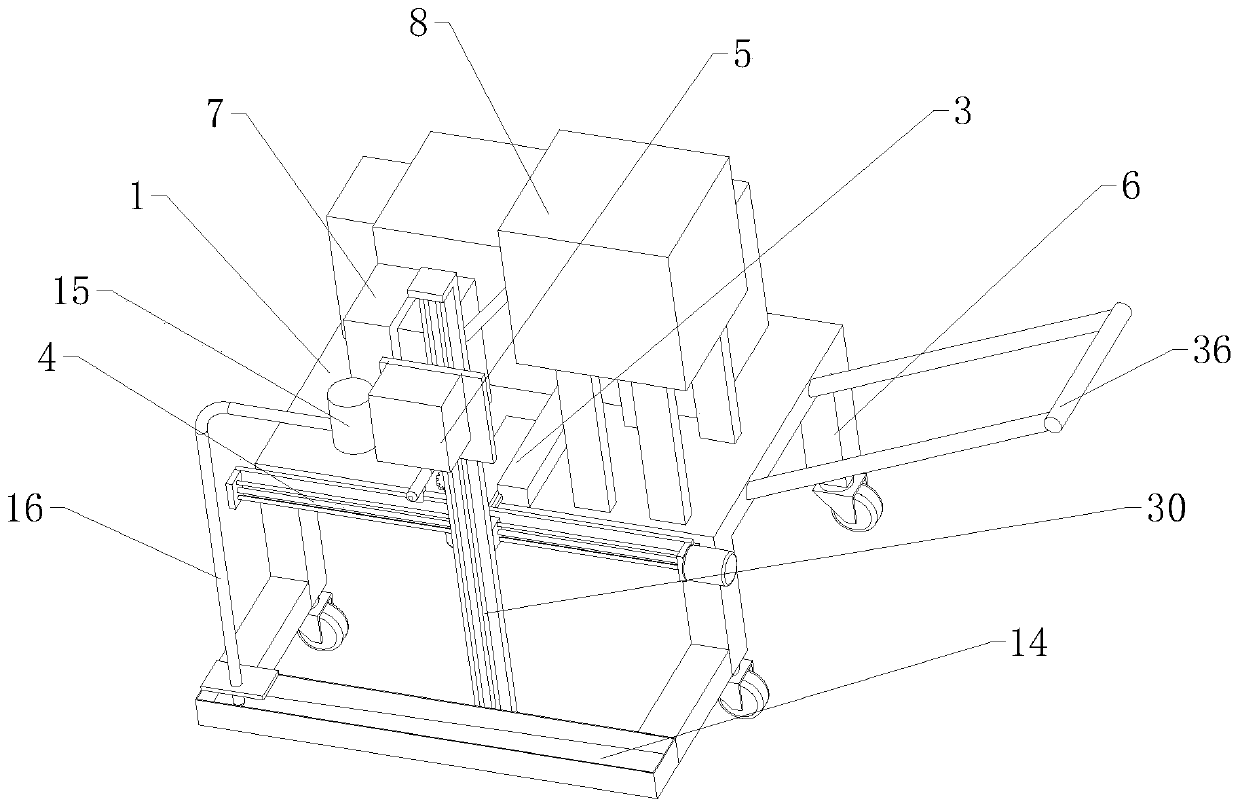

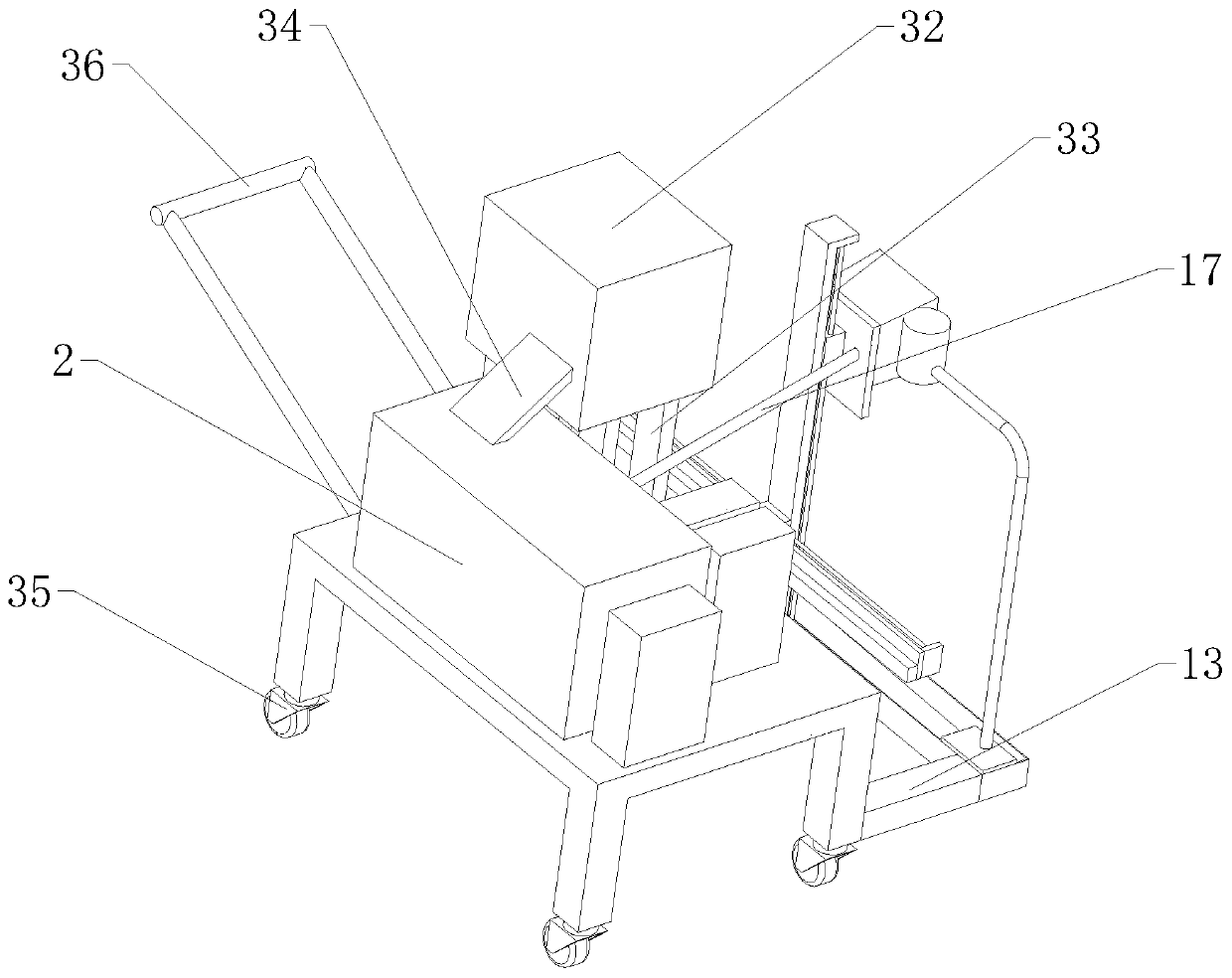

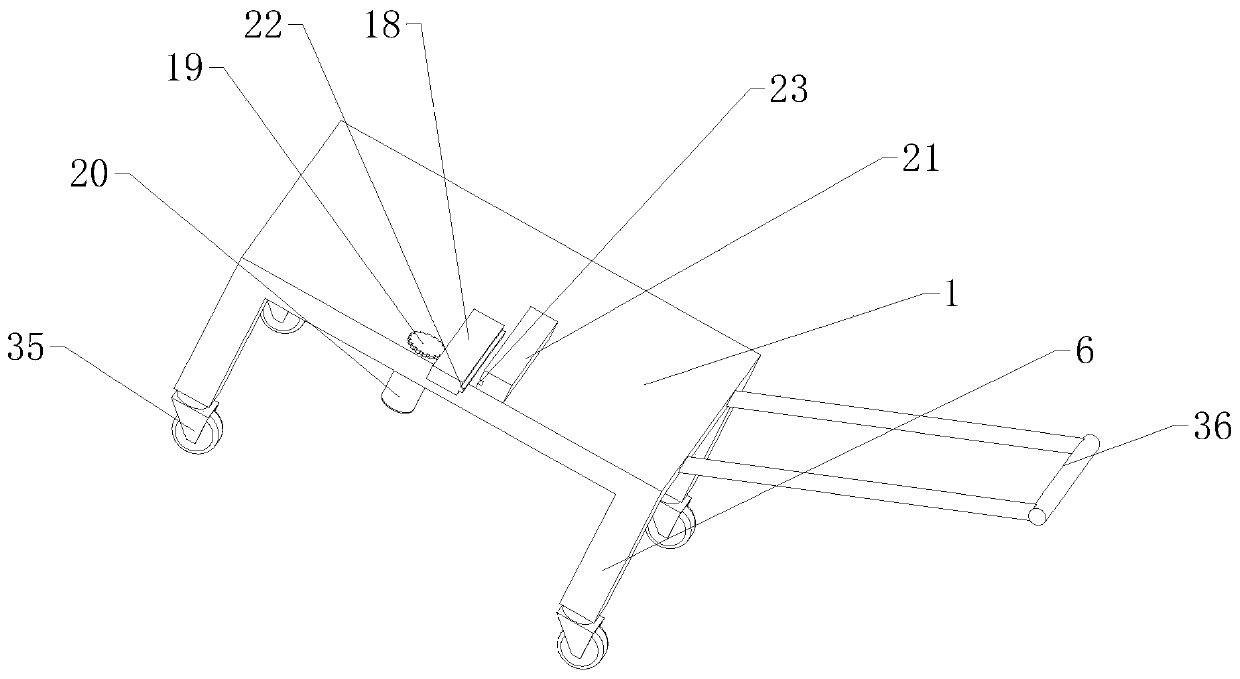

[0027] Embodiment 1: Reference Figure 1 to Figure 4 The shown external wall real stone paint spraying device includes a workbench 1, a manufacturing box 2, an adjustment mechanism 3, a longitudinal movement mechanism, a horizontal movement mechanism 4, and a spraying mechanism 5. The bottom of the workbench 1 is provided with a plurality of The support frame 6, the manufacturing box 2 is set on the workbench 1, and the side of the manufacturing box 2 is provided with a plurality of auxiliary material boxes 7 which are connected to the manufacturing box 2 through conveying pipes. The workbench 1 is also provided with a colored sand adding mechanism 8. The mechanism 3 is fixedly arranged on the left side of the workbench 1, the output end of the adjusting mechanism 3 is horizontally arranged with a mounting bar 9, the horizontal moving mechanism 4 is fixedly arranged on the mounting bar 9, and the longitudinal moving mechanism is fixedly arranged on the output of the horizontal m...

Embodiment approach 2

[0035] Embodiment 2: The connection method of the nozzle on the spray can is 360° rotation connection, in addition, the pump 15 and the spray can have a double-sided pluggable sealing connection design, the straw 16 is slidable in the receiving box, and the receiving box passes through two The hinged connection of the retractable installation column 13 and the standard connection design of the internal thread of the inner wall of the straw make it possible to spray paint normally and evenly on the wall regardless of the sloped ground, while also achieving normal paint drop. Recycling, and the inner wall thread of the suction pipe and the suction pipe design between the pump 15 and the suction pipe, so that the suction pipe and the pump can be quickly replaced with other equipment, such as skin grinding equipment or wall sanding equipment. The specific working process is as follows: The paint spraying device is near the wall, and according to the uneven distribution of the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com