A High Thermal Stability Locking Joint

A high thermal stability, joint technology, applied in the direction of shaft and bearing, pivot, pivot connection, etc., can solve the problems of affecting the thermal stability of the mechanism, unfavorable to the rigidity of the mechanism, poor structural symmetry, etc., to achieve high cutting reliability, The effect of small joint locking impact and secure pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

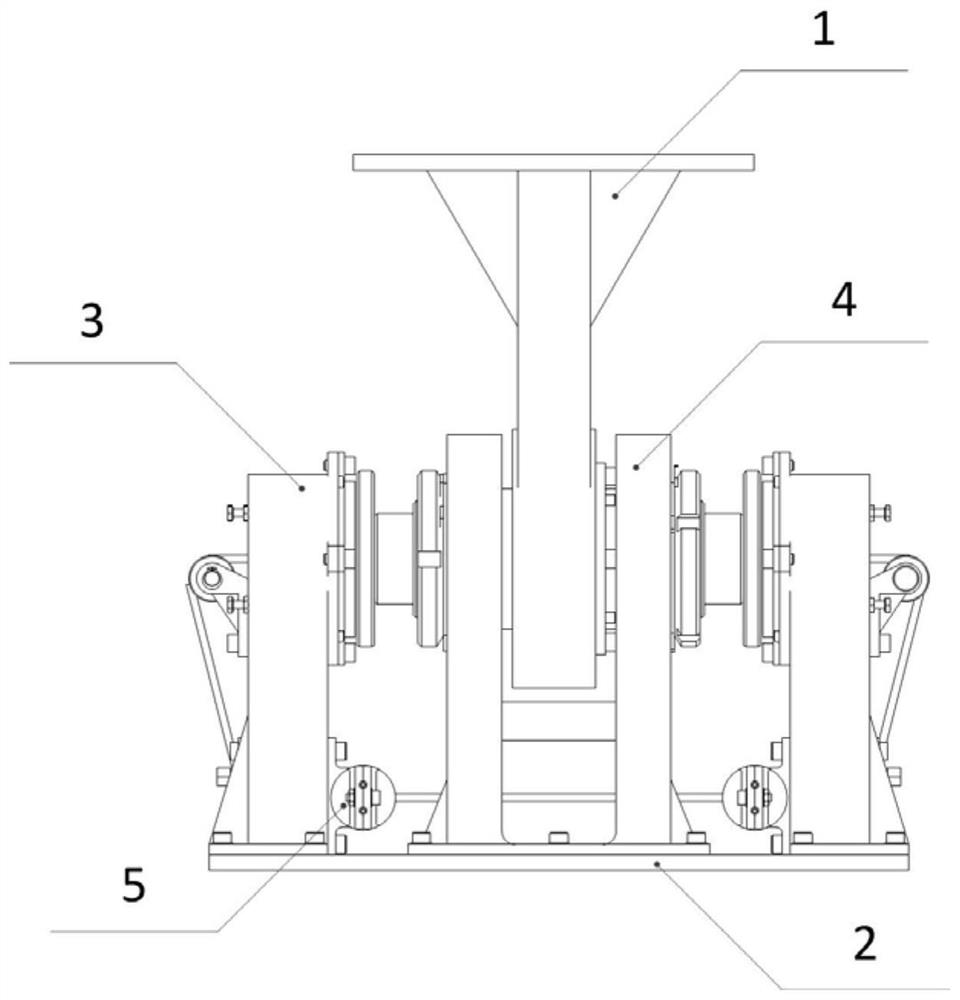

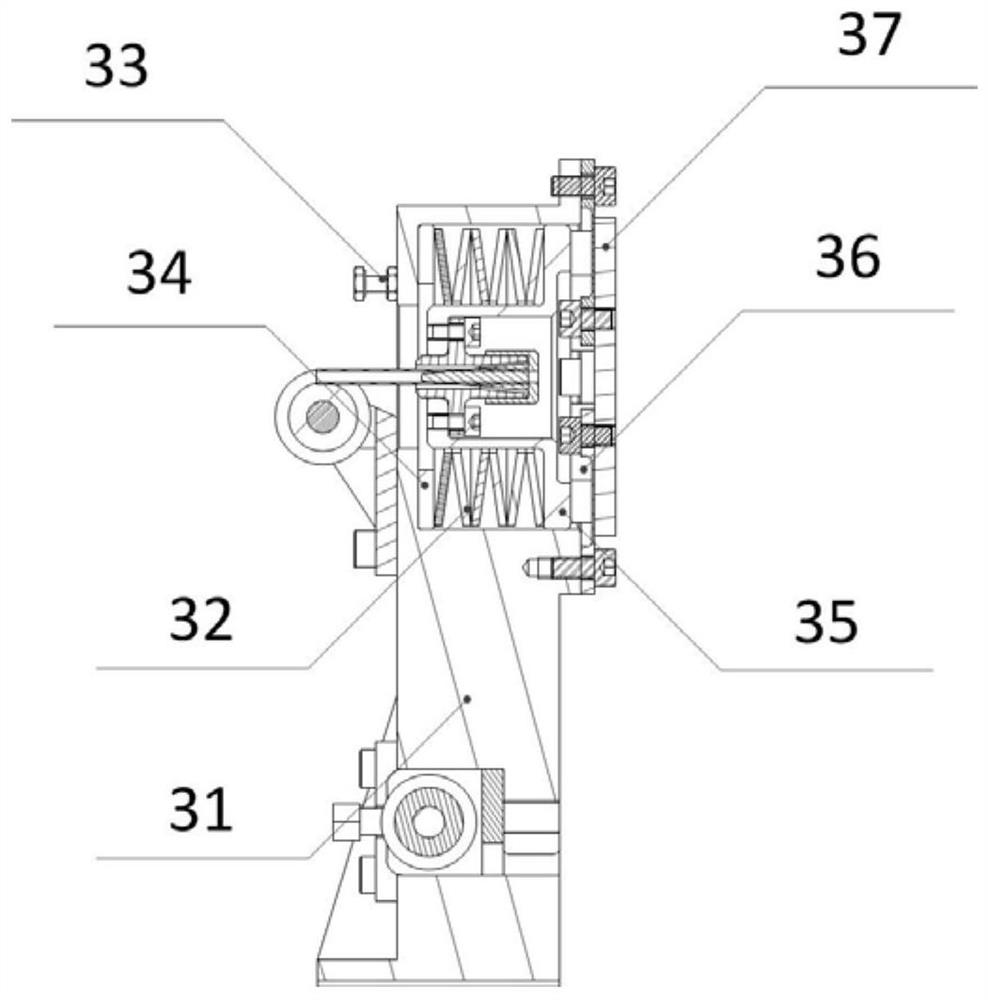

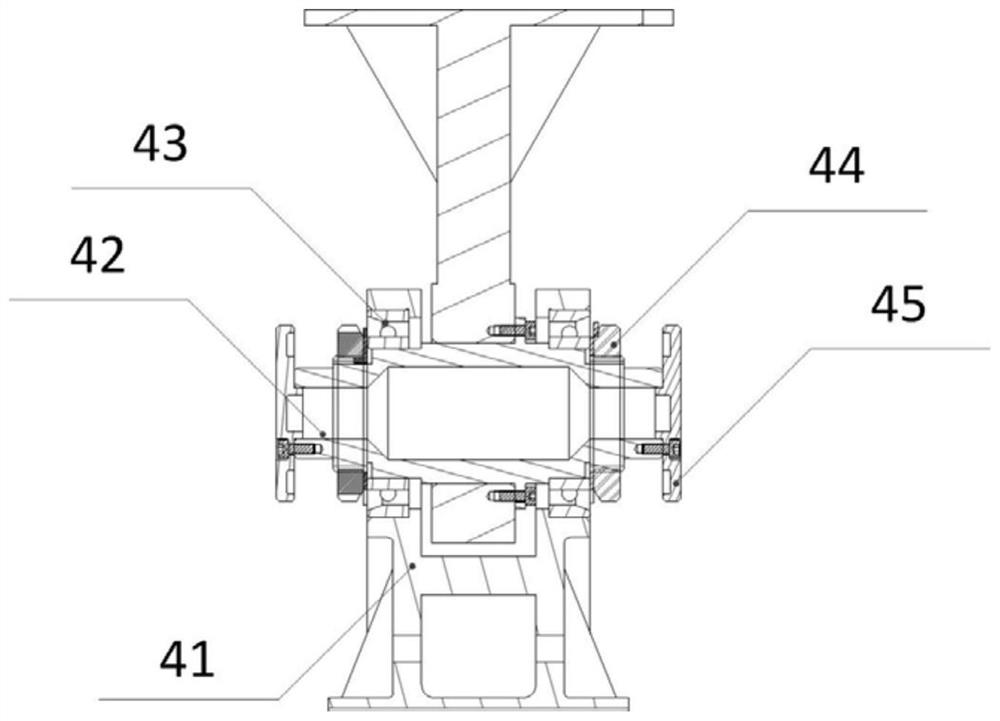

[0034] The invention discloses a locking joint with high thermal stability, comprising a first connecting piece 1, a second connecting piece 2, a constant pressure locking device 3, a rotating shaft assembly 4, and a low-impact release device 5; the first connecting piece 1 and the second The connectors 2 are respectively fixedly connected with a rod. The first connector 1 and the second connector 2 form a rotating pair through the rotating shaft 42 and the bearing 43, so that the first connecting member 1 and the second connecting member 2 are hinged, and the two ends of the rotating shaft 42 A constant pressure locking device 3 with constant pressing force is provided, and the constant pressure locking device 3 can realize locking through a low-impact release device 5 . The present invention realizes the two-plane symmetry of the entire joint with respect to the axis of the passing rod through the reasonable layout of the constant pressure locking device 3, the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com