A kind of visible light three-layer wave-lined colorful optical fiber and its manufacturing method

A technology of visible light and optical fiber, applied in cladding optical fiber, optical waveguide light guide, multi-layer core/clad optical fiber, etc., can solve the problems of colored light irradiation, quietness, and the existing technology of colorful lighting without ordinary mixed light sources, etc. problem, to achieve the effect of light dispersion and clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

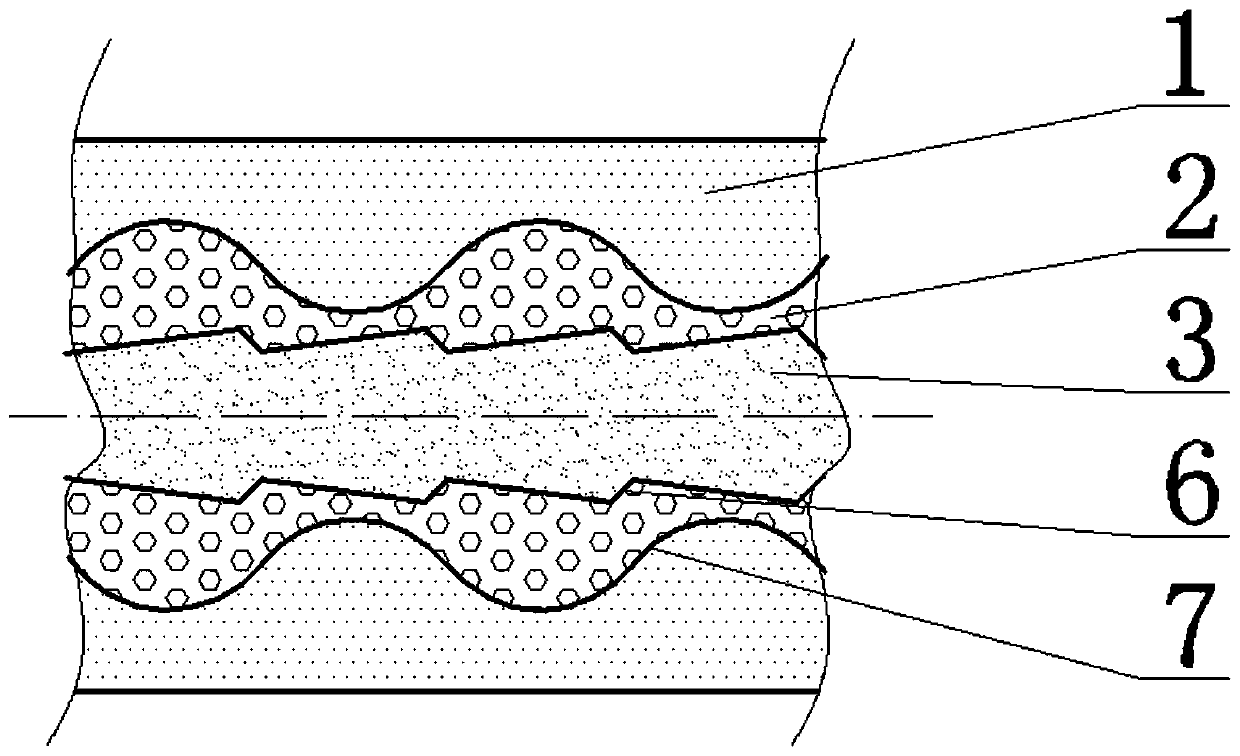

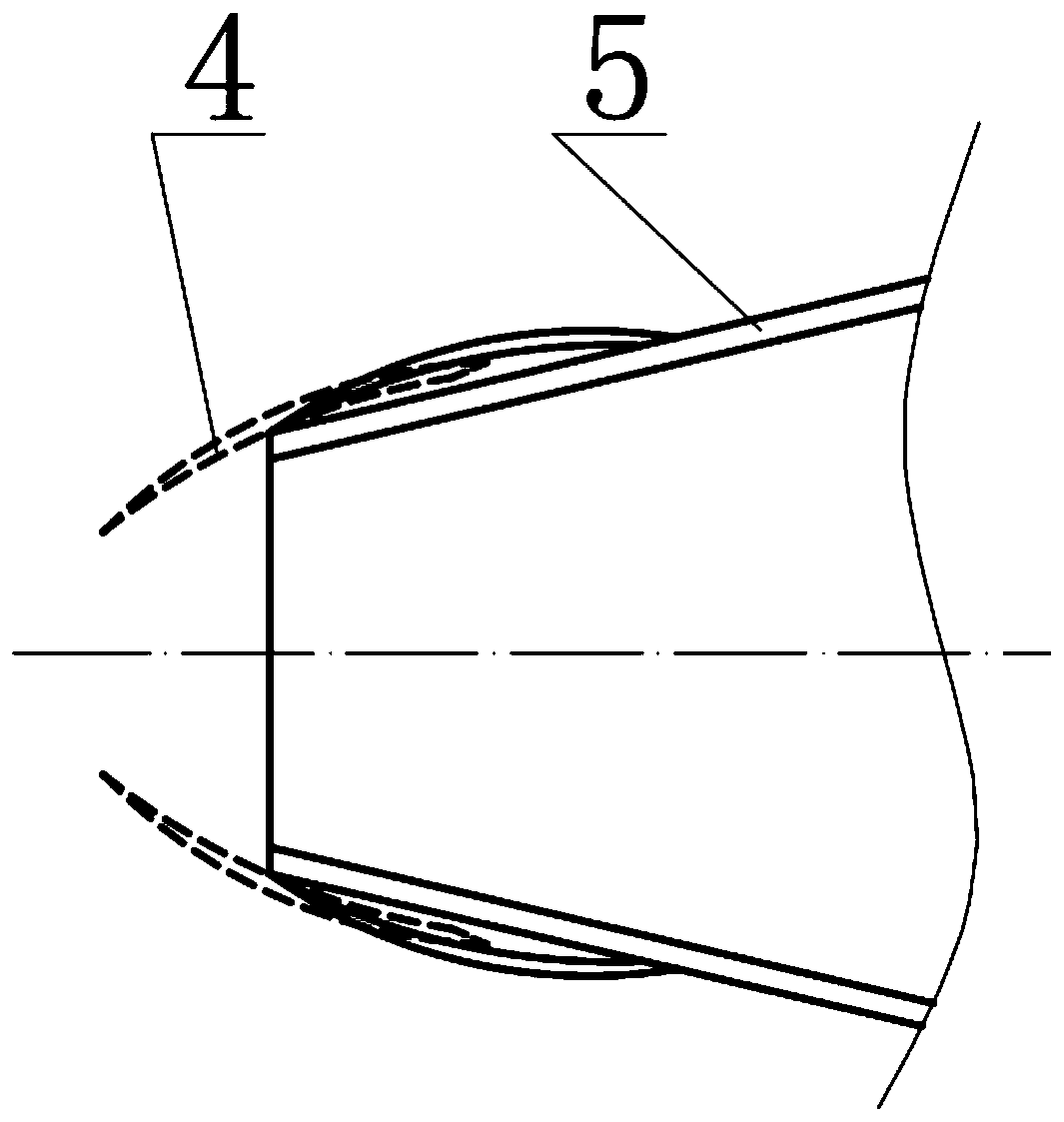

[0028] Such as figure 1 A visible light three-layer wave-lined colorful optical fiber is shown, the colorful optical fiber is composed of outer fluoromonomer methacrylate-2,2,2-trifluoroethyl ester polymer and bubble composite casing 1, the middle part The intermediate layer 2 composed of polymethyl methacrylate and glass slag particles and the inner aromatic polycarbonate core material 3, the longitudinal section of the casing 1 and the second layer 7 of the intermediate layer 2 is sinusoidal, and the sinusoidal wavelength is 20cm , the wave height is 0.3mm, the reference axis of the sine wave shape is parallel to the axis of the core material 3; the longitudinal section of the middle layer 2 and the first sub-layer 6 of the core material 3 is in a zigzag shape, and the dedendum connection lines corresponding to the dedendum between all teeth They are all parallel to the axis of the core material 3. The tooth surfaces of the sawtooth are divided into sunny slopes and shady sl...

Embodiment 2

[0045] The whole is consistent with Example 1, the difference is:

[0046] The longitudinal section of the shell 1 and the second layer 7 of the middle layer 2 is sinusoidal, with a sinusoidal wavelength of 24 cm and a wave height of 0.4 mm;

[0047] The longitudinal section of the first subdivision layer 6 is sawtooth-shaped, and the dedendum connection lines corresponding to the dedendum between all teeth are parallel to the axis of the core material 3. The tooth surfaces of the sawtooth are divided into sunny slopes and shady slopes, wherein The angle between the sunny slope surface and the line connecting the corresponding dedendum is 0.1°, the angle between the shady slope surface and the line connecting the corresponding dedendum is 1°, and the distance between adjacent dedendums is 10cm;

[0048] The outer diameter of the whole colorful optical fiber is 15mm;

[0049] The manufacturing method of the above-mentioned visible light three-layer wave-lined colorful optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com